Preparation method of hollow monofilament three-dimensional fabric

A fabric and monofilament technology, applied in the field of textile fabrics, can solve the problems of low silk strength, not fastness to light washing, poor color fastness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A hollow monofilament three-dimensional fabric, the preparation process of which is as follows:

[0034] (1) Select polyester-cotton blended CVS40 / 60, CVS45 / 55, CVS50 / 50, CVS55 / 45, CVS60 / 40 with yarn counts of 20S, 30S, 40S, 50S, 60S, 70S, 80S and yarn counts respectively Hollow polyester monofilaments of 20D, 30D, 40D, 50D, 60D, 70D, and 80D are woven into fabric gray fabric by single-sided circular weft jacquard loom.

[0035] The amount of polyester-cotton blended CVS is 80%, and the amount of hollow polyester monofilament is 20%.

[0036] Among them, 20S corresponds to 20D, 30S corresponds to 30D, and so on, a total of 35 kinds of gray fabrics are obtained.

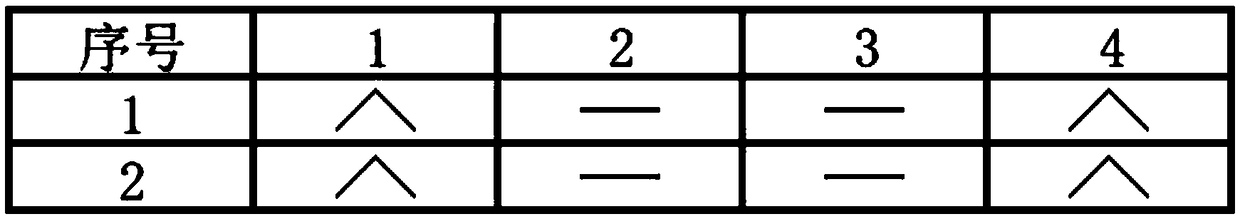

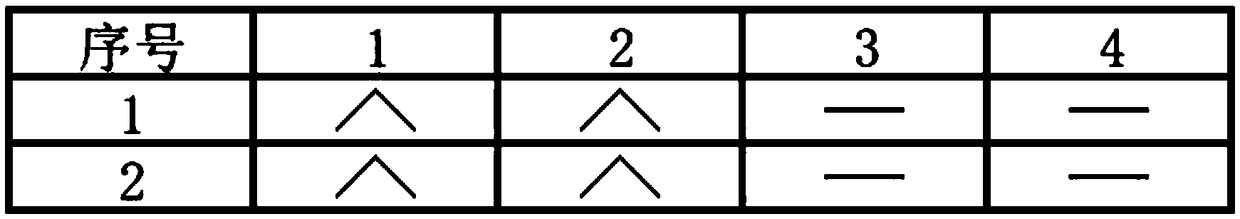

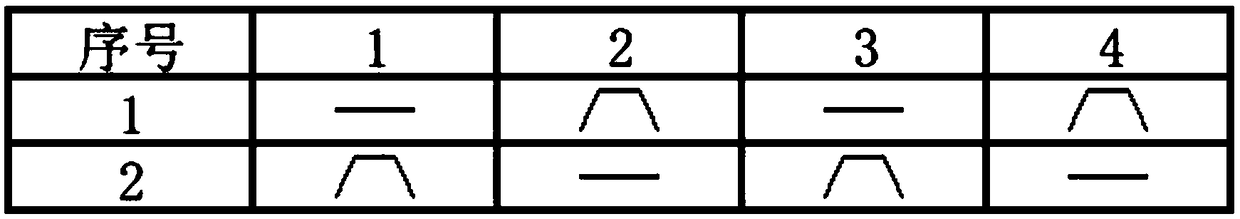

[0037] The fabric gray cloth has a staple fiber yarn surface, and several hollow polyester monofilaments are alternately woven up and down on the staple fiber yarn surface. Alternate up and down weaving, that is, the polyester-cotton blended fabric forms the short-fiber yarn surface, and the hollow polyester ...

Embodiment 2

[0052] (1) The polyester-cotton blended CVS55 / 45 with a yarn count of 40S and the hollow polyester monofilament with a yarn count of 40D are woven into a fabric gray fabric by a single-sided circular weft jacquard machine.

[0053] The dosage of CVS55 / 45 is 80%, 85%, 90%, 95% respectively, and the dosage of hollow polyester monofilament is 20%, 15%, 10%, 5%.

[0054] The weaving steps are the same as in Example 1.

[0055] The 4 fabric gray cloths after resetting are tested, and the test results are as follows:

[0056] 1) Shrinkage rate: vertical 2.4% ~ 3%, horizontal 3.5% ~ 4%

[0057] 2) Color fastness to washing 4~5, color fastness to perspiration 4~5, color fastness to water 4~5, color fastness to dry rubbing 4, color fastness to wet rubbing 3, color fastness to sweat Fastness level 4

[0058] 3) Bursting strength 70PSI ~ 75PSI, anti-pilling grade 3 ~ 4

[0059] Among them, the greige cloth of the fabric with the dosage of 85% CVS55 / 45 and the dosage of hollow polyest...

Embodiment 3

[0061] (1) The polyester-cotton blended CVS55 / 45 with a yarn count of 40S and the hollow polyester monofilament with a yarn count of 40D are woven into a fabric gray fabric by a single-sided circular weft jacquard machine.

[0062] The amount of CVS55 / 45 is 85%, and the amount of hollow polyester monofilament is 15%.

[0063] (2) Pre-shape the gray cloth of the fabric, the pre-shaping temperature is 150°C, 160°C, 170°C, 180°C, 200°C, and the speed is 15m / min, 20m / min, 25m / min, 30m / min .

[0064] All the other steps are the same as in Example 1.

[0065] The 20 greige fabrics that were re-shaped were monitored, and the test results were as follows:

[0066] 1) Shrinkage rate: vertical 2.4% to 3.5%, horizontal 3.5% to 4.5%;

[0067] 2) Color fastness to washing 4~5, color fastness to perspiration 4~5, color fastness to water 4~5, color fastness to dry rubbing 4, color fastness to wet rubbing 3, color fastness to sweat Fastness level 4;

[0068] 3) Bursting strength 70PSI ~ ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bursting strength | aaaaa | aaaaa |

| Bursting strength | aaaaa | aaaaa |

| Bursting strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com