Hydraulic chuck for core drilling machines

A technology for hydraulic chucks and core drilling rigs, which is applied to drill pipes, drill pipes, and drilling equipment. It can solve problems such as slippage, deflection of underground torque transmission, and weakened clamping force. It achieves low loss, good economy, and Neutral good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The hydraulic chuck of the core drill of the present invention will be further described in detail below through specific examples.

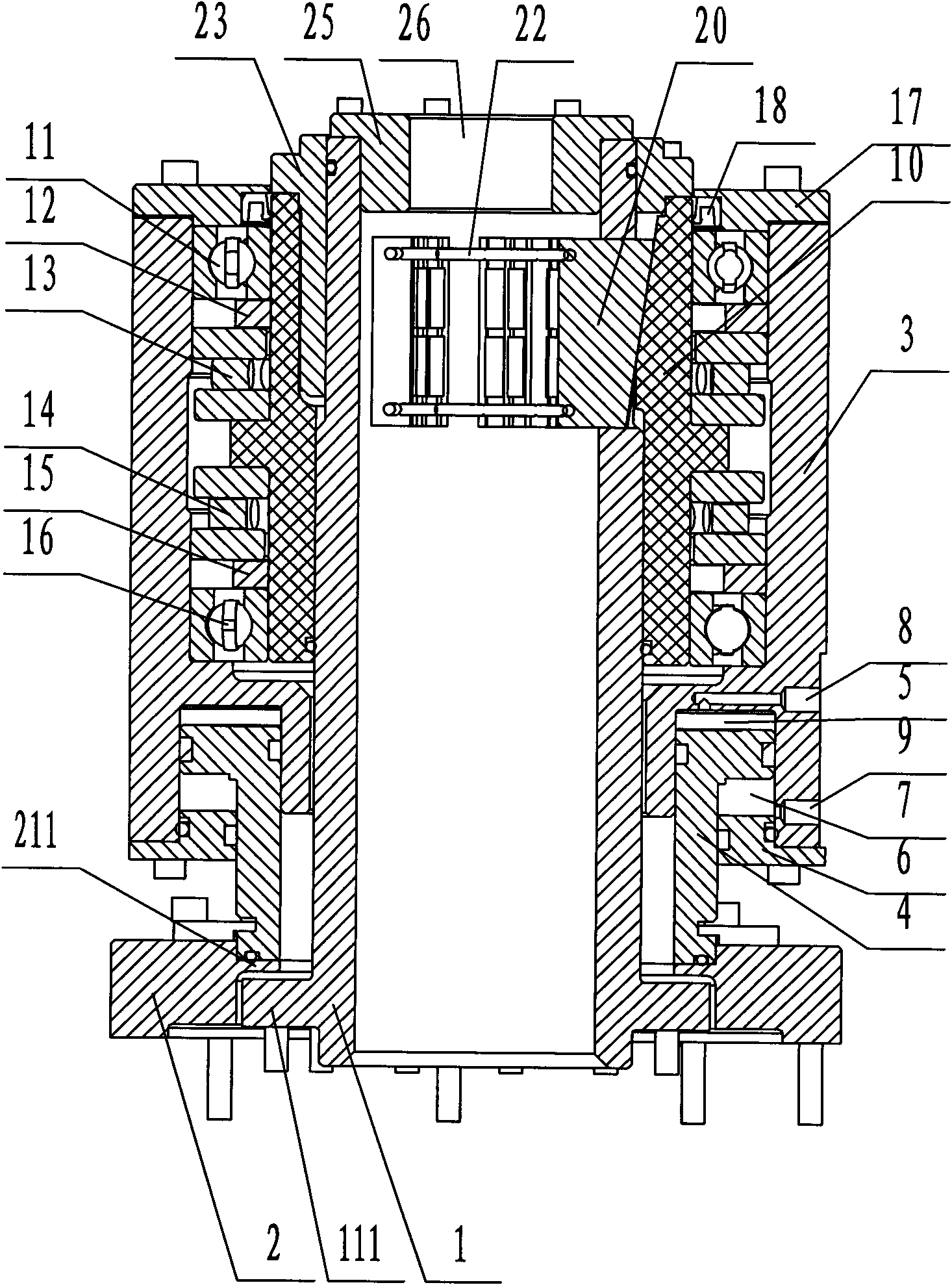

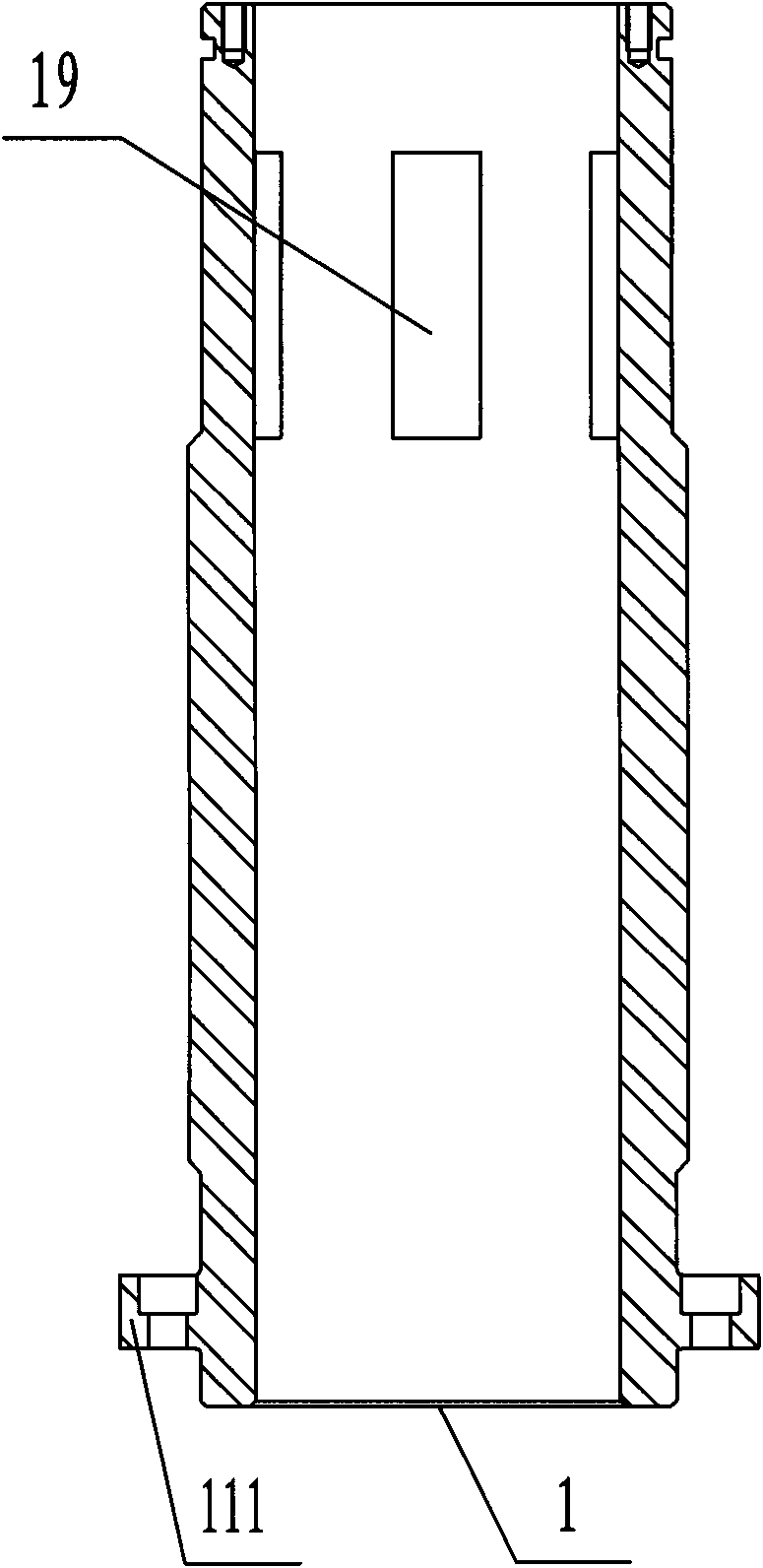

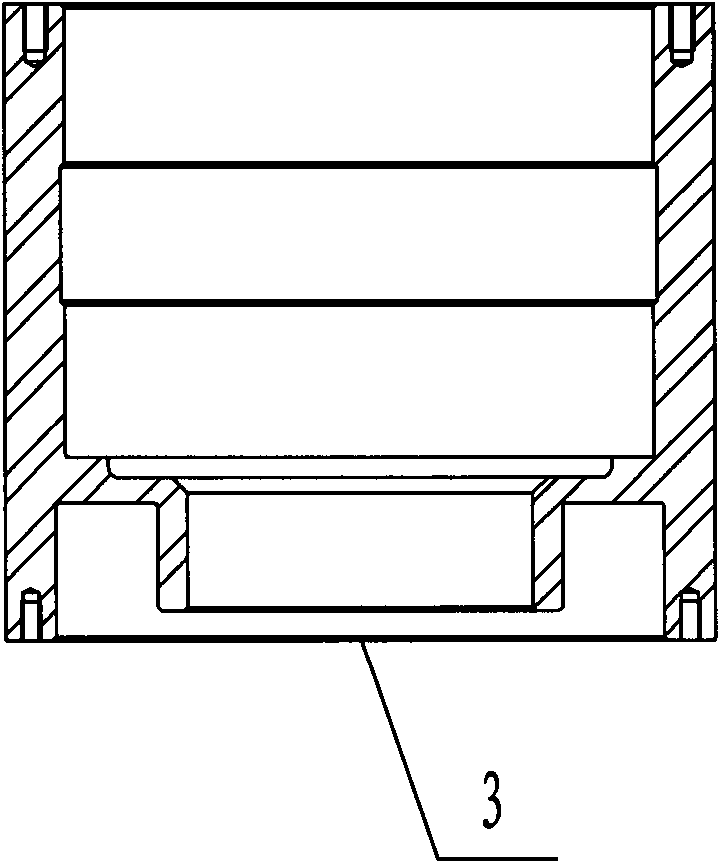

[0028] Such as figure 1 As shown, the hydraulic chuck of a core drilling machine includes a hollow mandrel 1. The lower part of the outer wall of the mandrel 1 is movably arranged in the power head cover 2, and the lower part of the outer wall of the mandrel 1 is provided with a boss 111. A limit block 211 is provided on the power head cover 2 of the power head. The limit block 211 is located above the boss 111 and is used for the axial limit between the spindle 1 and the power head cover 2. A chuck oil cylinder is provided on the outside, and the structure of the chuck oil cylinder is: an outer cylinder liner 3, and the structure of the outer cylinder liner 3 is as image 3 As shown, the inner cylinder liner 4 is movably sleeved in the cavity at the lower end of the outer cylinder liner 3, an upper oil chamber 5 is formed between the outer c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com