Three-dimensional source separated pressure-releasing gas treatment method

A technology of separating source and gas, applied in the directions of gas discharge, earth-moving drilling, safety devices, etc., can solve the problems of gas influx, gas overrun, etc., to eliminate gas overrun, reduce gas overrun, and widely practicable Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

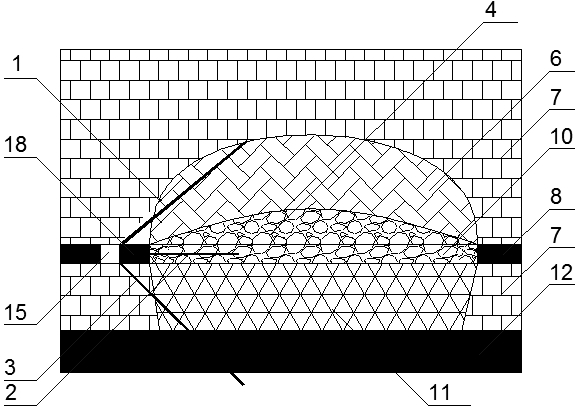

[0016] In this embodiment, the gas treatment method in the case where the protected layer 12 is in the lower part of the protective layer 8 is taken as an example, as figure 2 shown. Under the condition of coal seam group, the coal seam with no risk of coal and gas outburst or less risk of coal and gas outburst is selected to be mined first. The coal seam mined first is called protective layer 8. After the mining of protective layer 8, the risk of outburst in adjacent coal seams is eliminated or reduced. The coal seam is called the protected layer 12, and the protected layer 12 appears on the upper part of the protective layer 8, and also appears on the lower part of the protective layer 8.

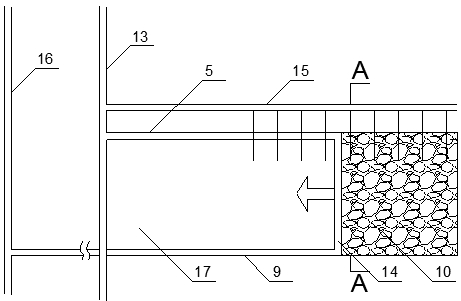

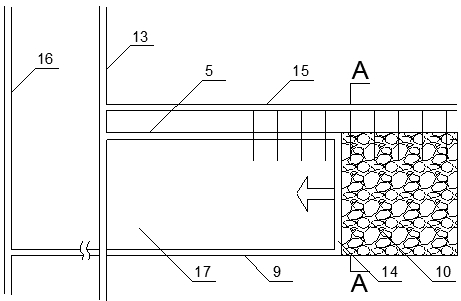

[0017] figure 1 As shown, in the three-dimensional split-source pressure relief gas treatment method of the present invention, first, after the preparation of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com