Porous rubber material member and full-frequency range vibration acoustical property analysis method thereof

A technology of porous rubber and statistical energy analysis, which is applied in the field of porous rubber material components and their full-range vibro-acoustic performance analysis, and can solve problems such as inability to predict vibration and acoustic response in the intermediate frequency region

Active Publication Date: 2011-06-15

ZHEJIANG UNIV OF TECH

View PDF6 Cites 24 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

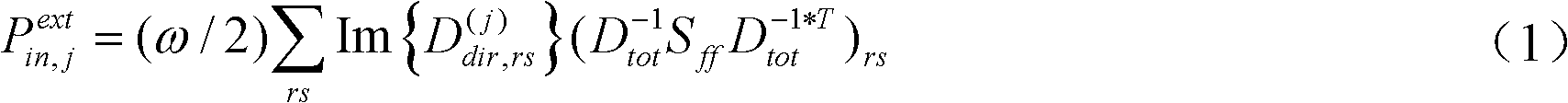

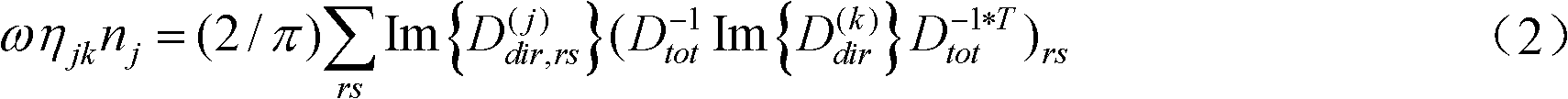

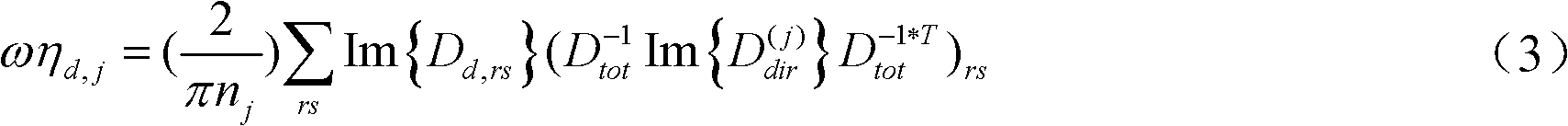

The traditional finite element analysis method (FiniteElementAnalysis-FEA) and statistical energy analysis method (StatisticalEnergyAnalysis-SEA) can better analyze and calculate the response of vibration and sound in the low frequency and high frequency range respectively, but these two methods are not effective Prediction of vibration and acoustic responses in the mid-frequency region

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a porous rubber material member. The member comprises a thin covering layer and a hole sound absorption layer which are integrated and made of a rubber material, wherein holes of the hole sound absorption layer are blind holes. The hole condition of the porous rubber material member is different from that of the common porous sound insulation material; in order to exert a sound absorption function, air holes of the common porous material are open and intercommunicated, and sound absorption property is higher when the number of the air holes is larger; the blind holes are directly and vertically punched on a rubber plate, so the porous rubber material member is suitable for vibration reduction and sound insulation in an air medium, and meets the requirement of certain pressure resistance when underwater equipment works in a deep water area; movement resistance can be reduced because the porous rubber material member has smooth appearance; in addition, the hole sound absorption layer and the thin covering layer are combined to form a composite structure, so the porous rubber material member has high sound absorption and sound insulation properties.

Description

A porous rubber material component and its full-range vibro-acoustic performance analysis method technical field The invention relates to a porous rubber material component and a method for analyzing its full-frequency vibration-acoustic performance. Background technique Rubber is a kind of structural vibration damping material with viscoelasticity. In addition to the damping performance of suppressing vibration, the porous rubber material component also has excellent properties such as sound insulation, sound absorption, heat resistance, cold resistance, and flame retardancy, so it is very suitable for use. As a vibration and noise reduction actuator for large equipment. Scientists at home and abroad began research on porous rubber materials and their acoustic properties as early as the end of the 1930s. However, previous research work has mainly focused on the sound-absorbing properties of porous rubber materials. There are not many published literatures about its acou...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F16F1/377G06F17/50

Inventor 应申舜卢奂采姜伟

Owner ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com