Double-purpose valve

A dual-purpose, valve stem technology, applied in valve details, valve device, valve operation/release device, etc., can solve the problems of inconvenient operation, low work efficiency, slow opening and closing speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

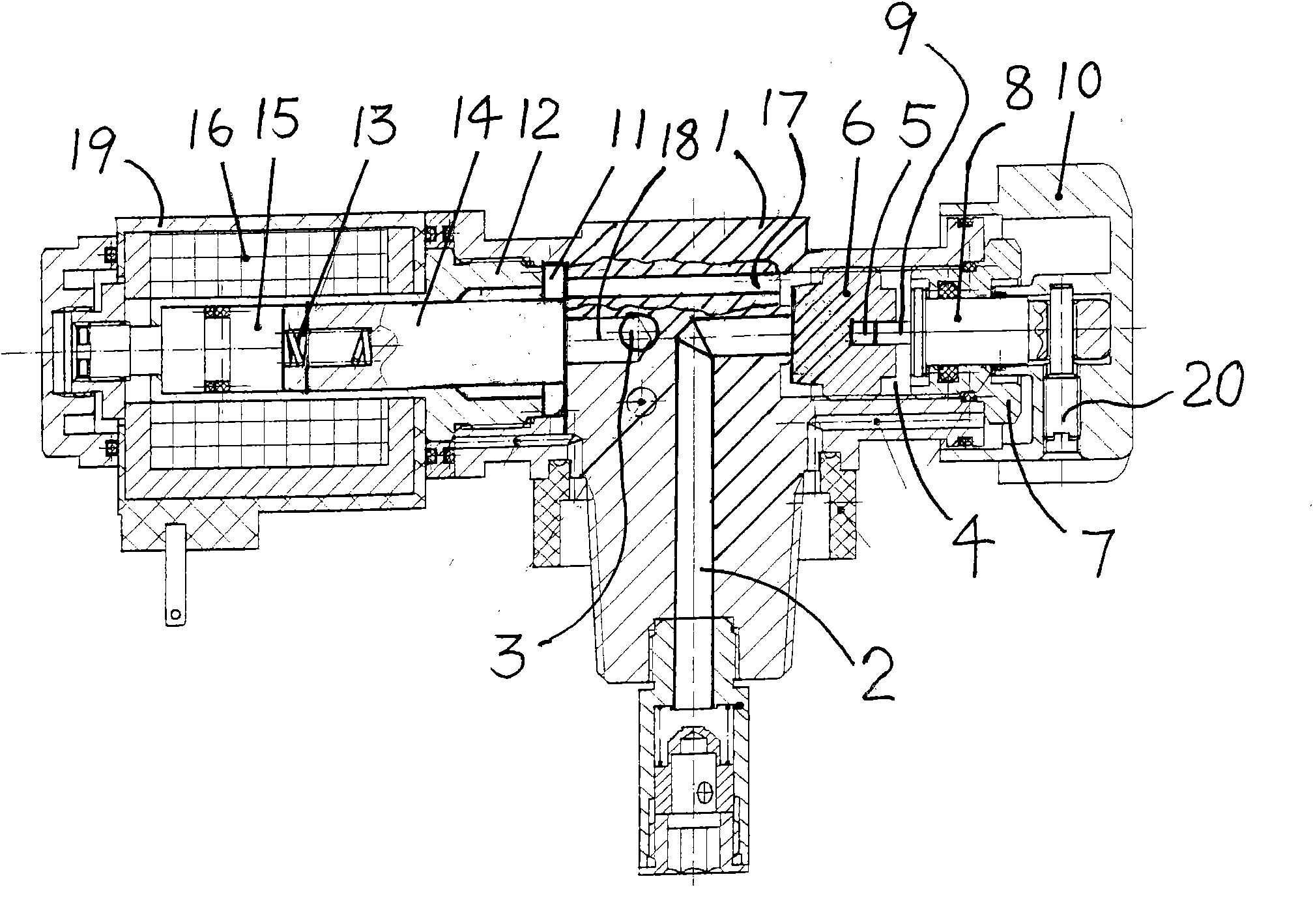

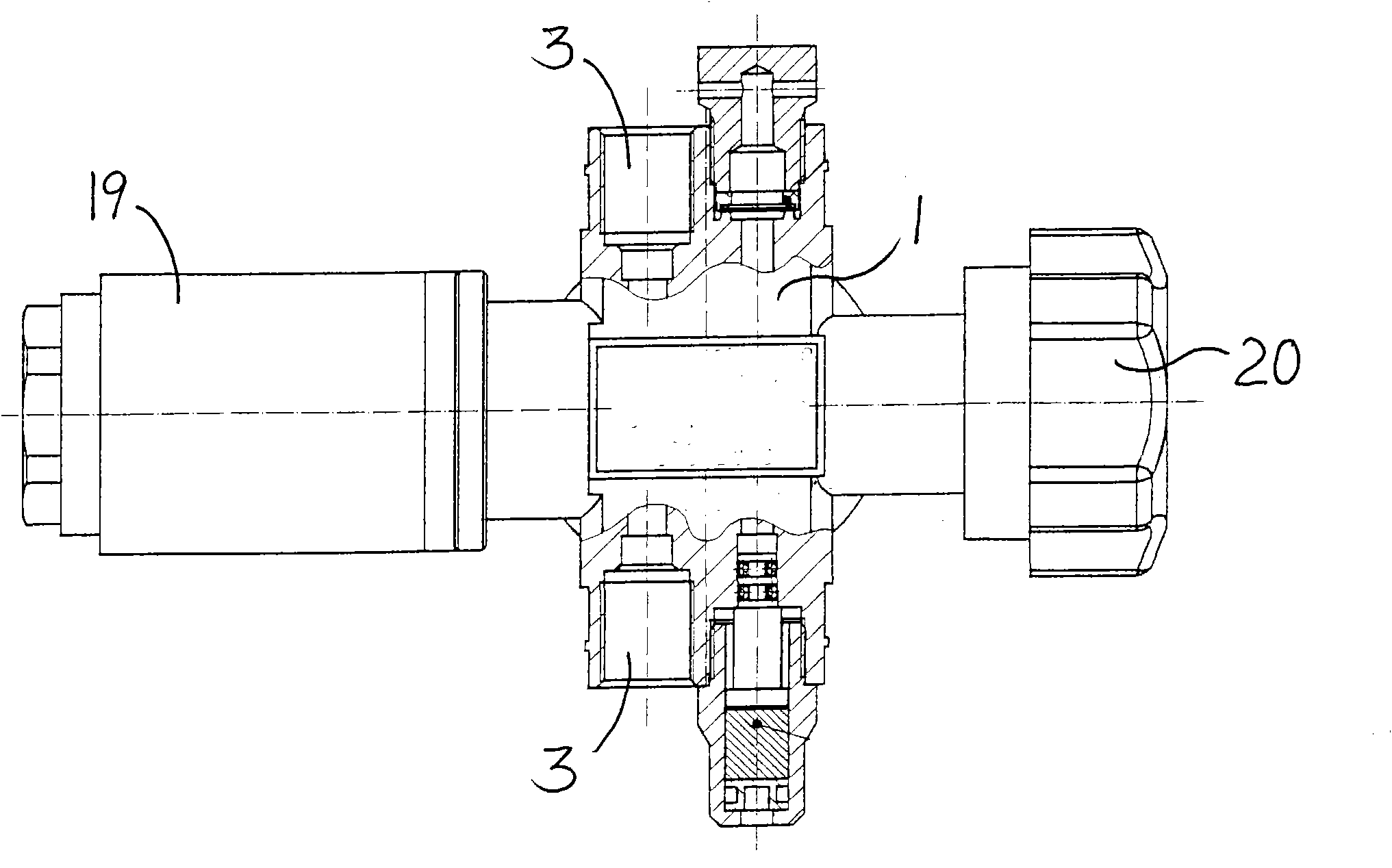

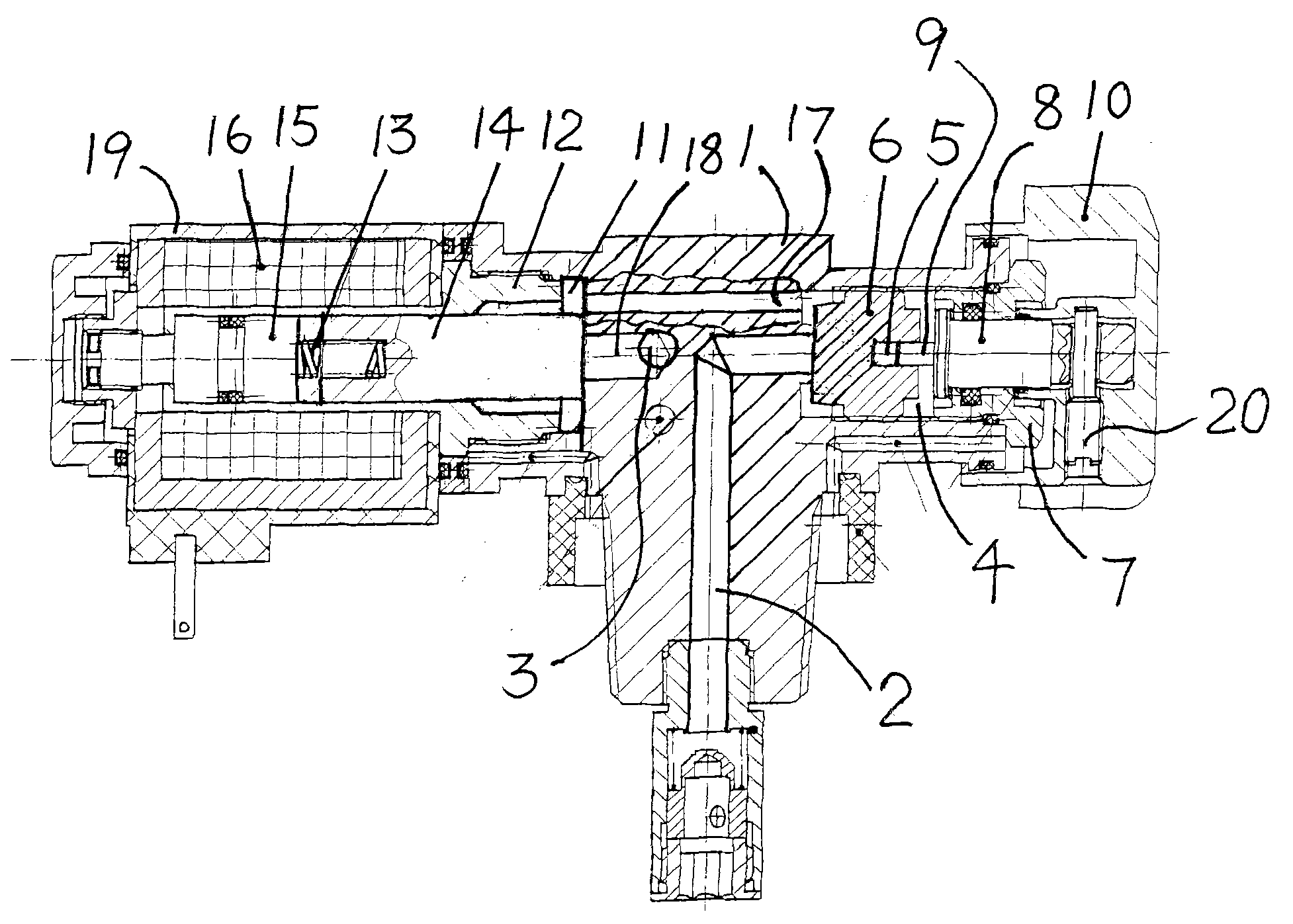

[0008] Embodiment 1: refer to figure 1 figure 2 . figure 1 The left side is the solenoid valve, and the right side is the manual valve. The valve of the manual valve closes the gas source port, and the moving iron core of the solenoid valve closes the second transition hole. Gas or liquid cannot pass from the gas source port to the gas outlet. Twist the handwheel to make the valve stem and the insert on it rotate synchronously with the handwheel, and at the same time, because the insert is embedded in the slot of the valve, the valve (to the right) that is threaded with the counterbore is forced to move in a straight line, so that the valve is separated from the air source At this time, the gas or liquid enters the sink hole through the gas source port, then enters the first transition hole through the sink hole and stays in the connection port on the left side of the first transition hole, and then applies a working voltage to the electromagnetic coil to move The magnetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com