Machine core structure of heavy load holder

A technology of a gimbal and movement, applied in the field of cameras, can solve the problems such as the misalignment of the occlusal surfaces of the horizontal worm gear and the horizontal worm, affecting the horizontal image quality of the camera, affecting the smoothness and stability of the heavy-duty gimbal, and solving the error gap of the worm gear and the worm. , smooth rotation, good horizontal image quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the drawings and examples.

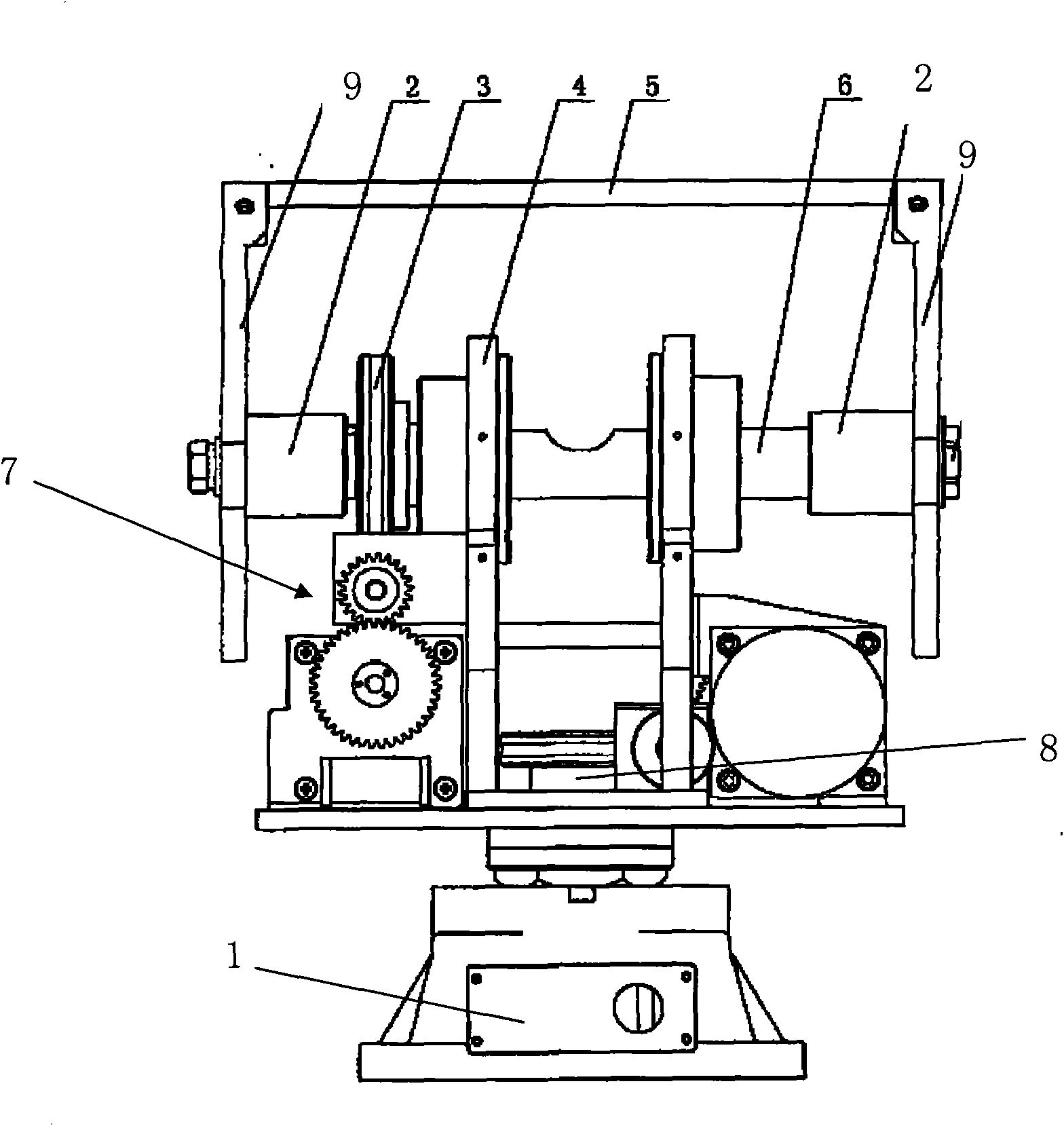

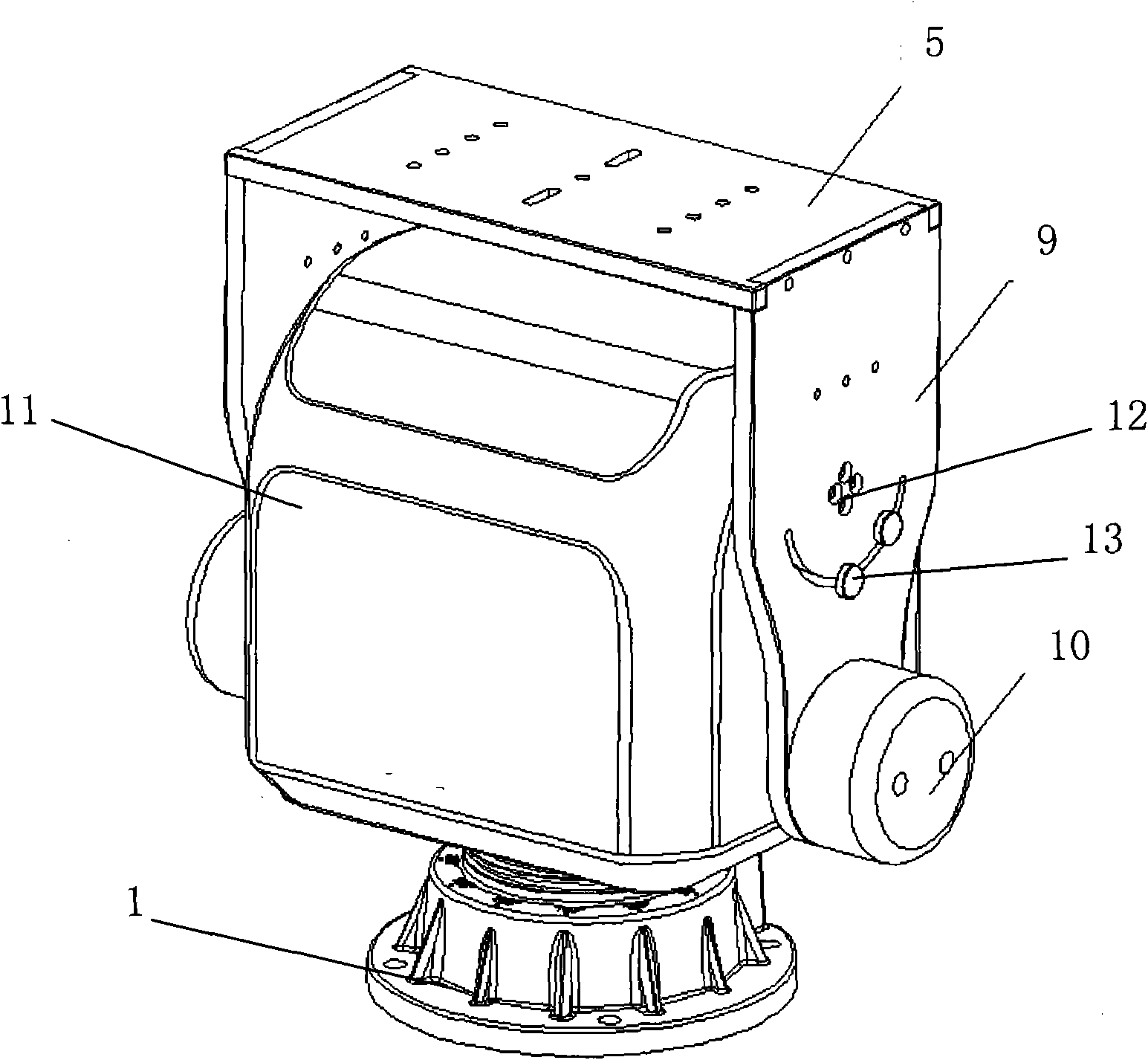

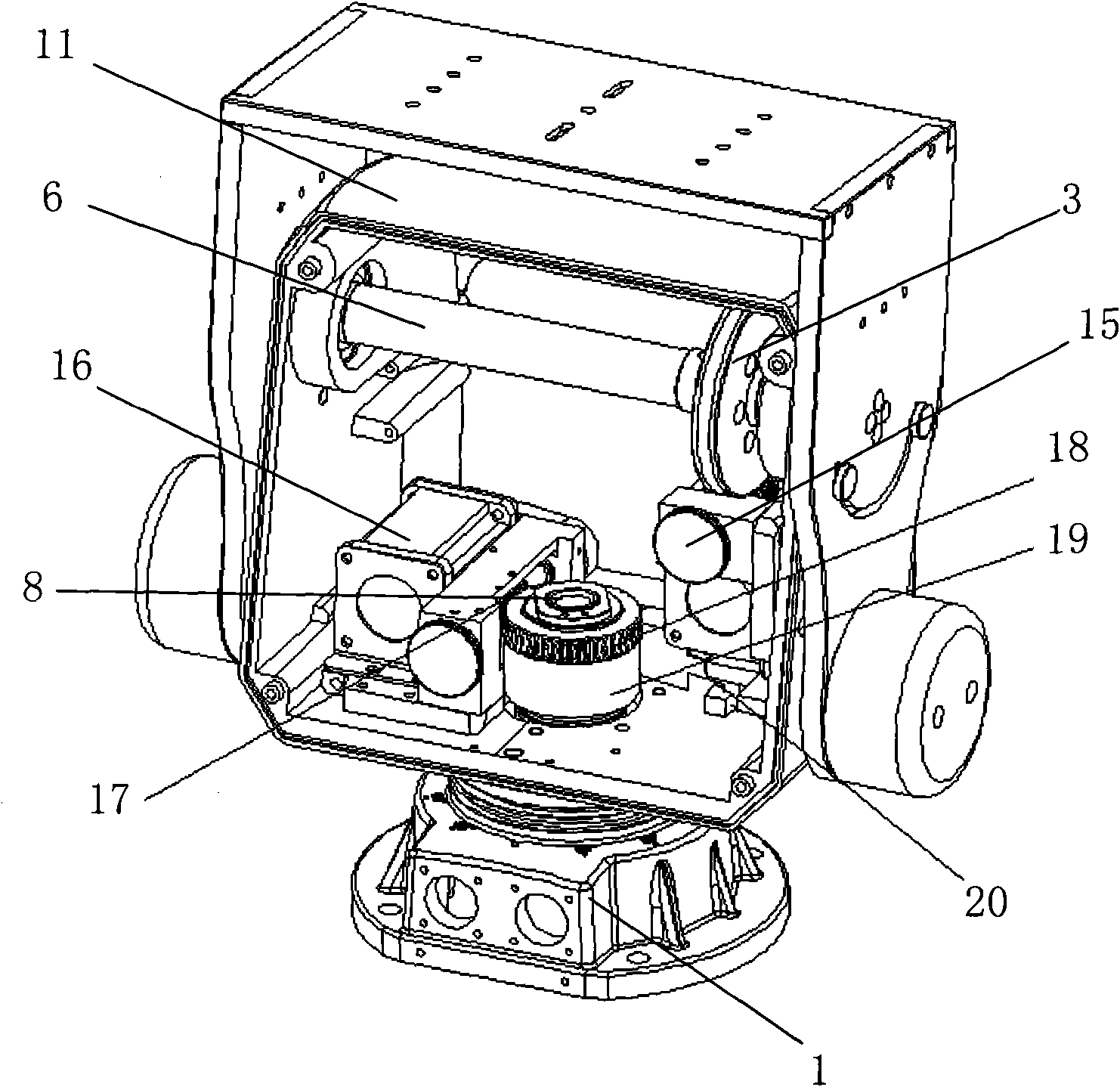

[0024] figure 2 It is a structural representation of the heavy-duty platform of the present invention; image 3 It is a schematic diagram of the movement structure of the heavy-duty platform of the present invention; Figure 4 It is a plan view of the movement structure of the heavy-duty platform of the present invention in the horizontal worm gear part.

[0025] Such as Figure 2 to Figure 4 As shown, the heavy-duty pan / tilt includes: base 1, fixed to the preset position of the camera, supporting the heavy-duty pan / tilt and the camera; The fixed camera rotates vertically and horizontally; the casing 11 is arranged outside the core to surround and protect the core; the shield is connected by the end plates 9 respectively arranged on both sides of the shell and the shields connecting the end plates plate 5, the camera is fixed on the shield connecting plate, and mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com