Dedusting and desulfurization synergistic comprehensive energy-saving and emission-reducing device based on flue gas cooling

An energy-saving device and flue gas cooling technology, applied in the field of power station boilers, can solve the problems of the loss of meaning of the booster fan, the reduction of fan efficiency, and the increase of initial investment, and achieve the effect of simple structure, stable operation and small investment.

Inactive Publication Date: 2011-06-15

XI AN JIAOTONG UNIV +1

View PDF5 Cites 22 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

With the continuous improvement of environmental protection requirements, the bypass flue of the desulfurization system is no longer installed in the new units, and the bypass flue of the in-service units will also be cancelled. The cancellation of the bypass flue and GGH will cause the booster fan to lose its existence.

If the arrangement of the booster fan and the induced draft fan is still adopted separately, a lot of space will be wasted, unnecessary initial investment will be increased, and the working point of the booster fan and the induced draft fan will be asynchronously, resulting in a decrease in fan efficiency.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

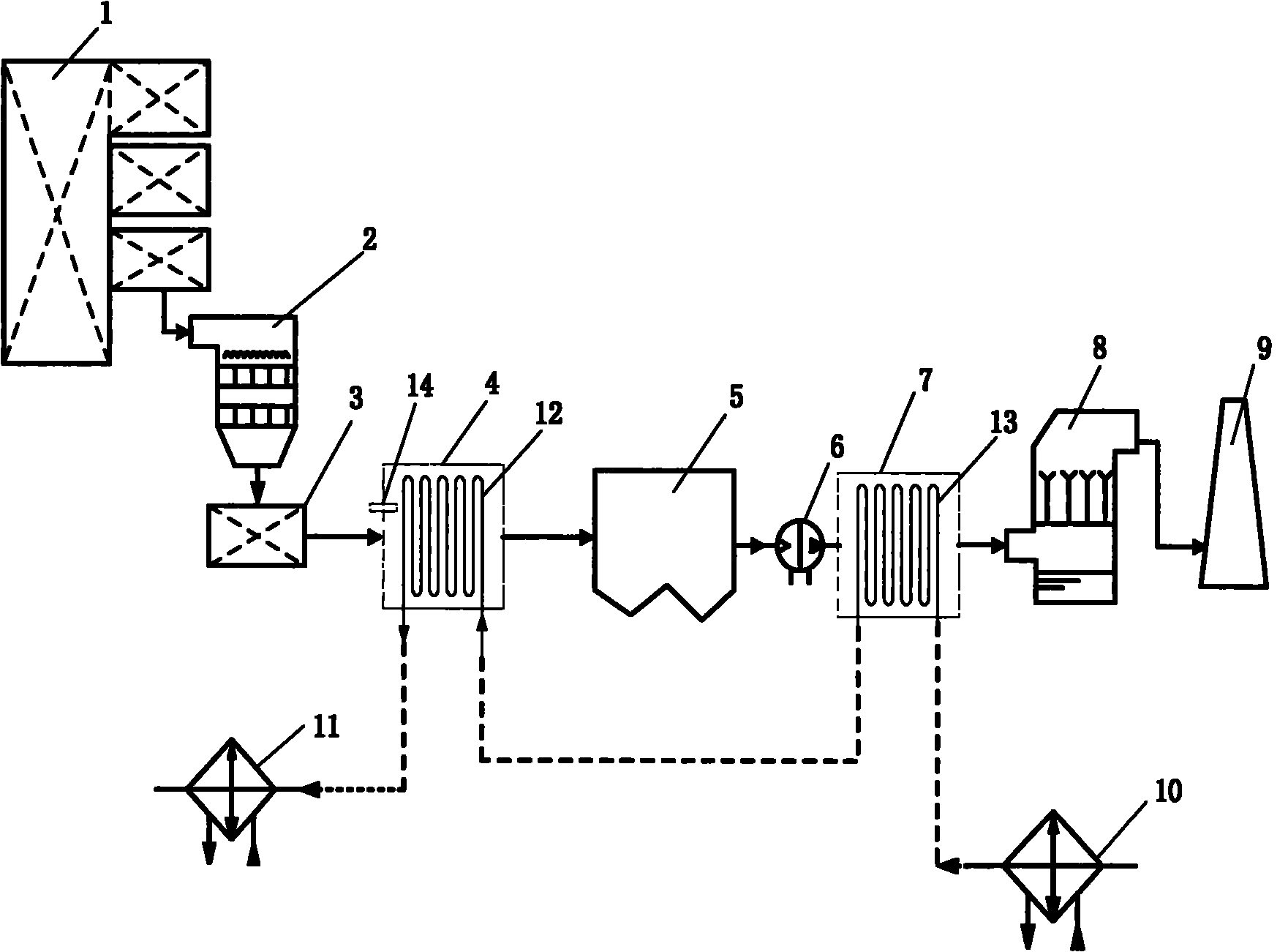

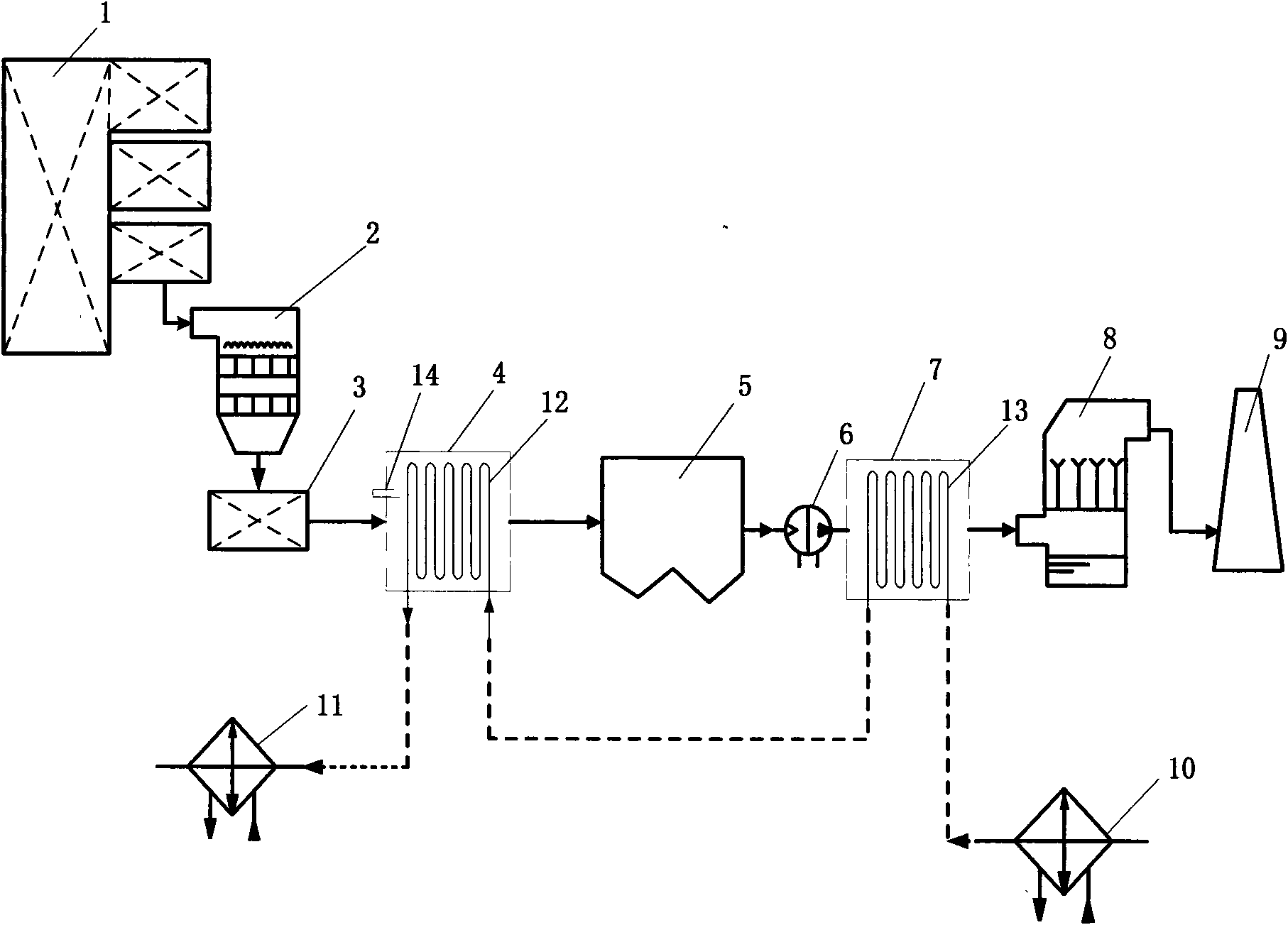

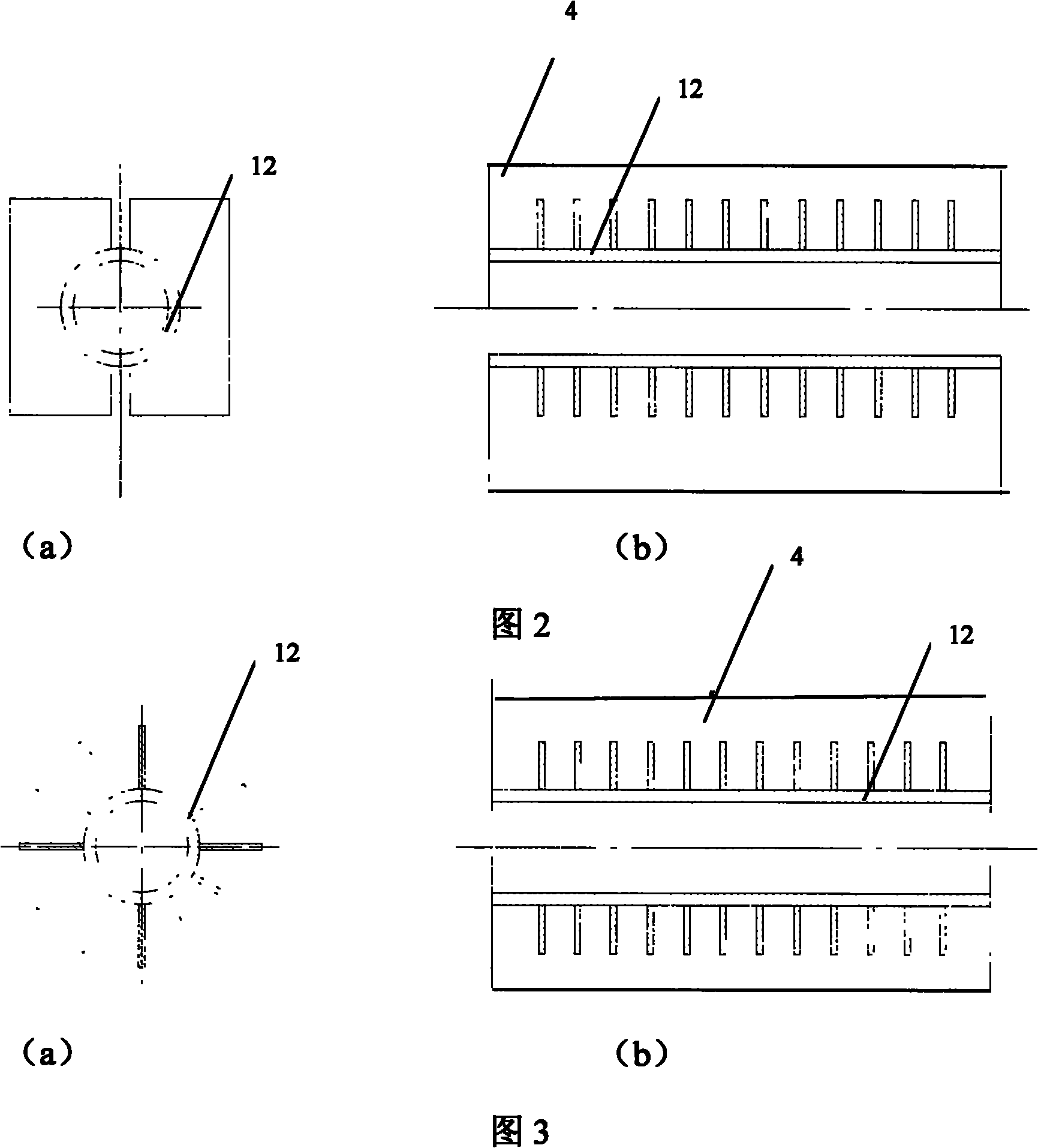

The invention relates to a dedusting and desulfurization synergistic comprehensive energy-saving and emission-reducing device based on flue gas cooling, the energy-saving desulfurization and dedusting synergistic comprehensive control technology taking the flue gas cooling as the core is adopted, and the device has the characteristics of low investment, simple structure, obvious effects and is stable in operation and can complete energy-saving synergy, desulfurization synergy, dedusting synergy and system transformation for optimizing an induced draft fan and a booster fan and realize the purposes of energy conservation and emission reduction with integrated comprehensive control.

Description

A comprehensive energy saving and emission reduction device for dust removal, desulfurization and efficiency enhancement based on flue gas cooling technical field The invention belongs to the technical field of power plant boilers, and in particular relates to a comprehensive energy-saving and emission-reducing device for dust removal, desulfurization and efficiency enhancement based on flue gas cooling. Background technique In recent years, the average annual output of raw coal in my country is about 3.05 billion tons, and the raw coal for power generation is 1.56 billion tons. Coal-based thermal power generation still accounts for more than 80% of the total power generation. For thermal power plants, the exhaust heat loss is the largest among all the heat losses of the boiler, generally 5% to 8%, accounting for 80% or more of the total heat loss of the boiler. The main factor affecting the heat loss of the exhaust gas is the exhaust gas temperature of the boiler. The act...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F23J15/00

Inventor 赵钦新张知翔姜衍更王云刚成丁南鲍颖群苟远波

Owner XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com