System and method for recognizing different defect types in paper defect visual detection

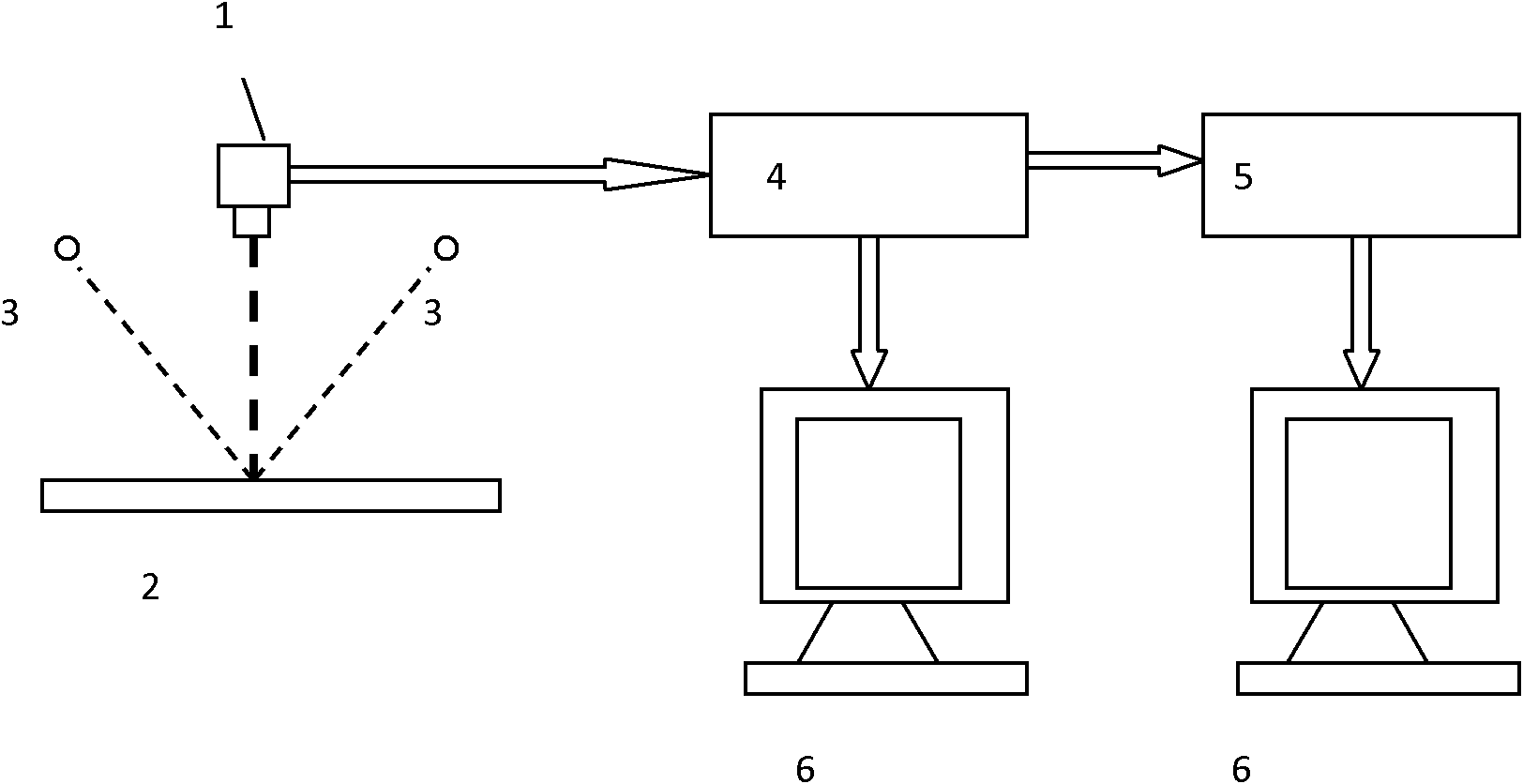

A technology for visual inspection and defect types, which is applied in the field of systems for identifying different defect types, and can solve problems such as increasing the difficulty of inspection and difficulty in real-time processing by PCs and industrial computers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

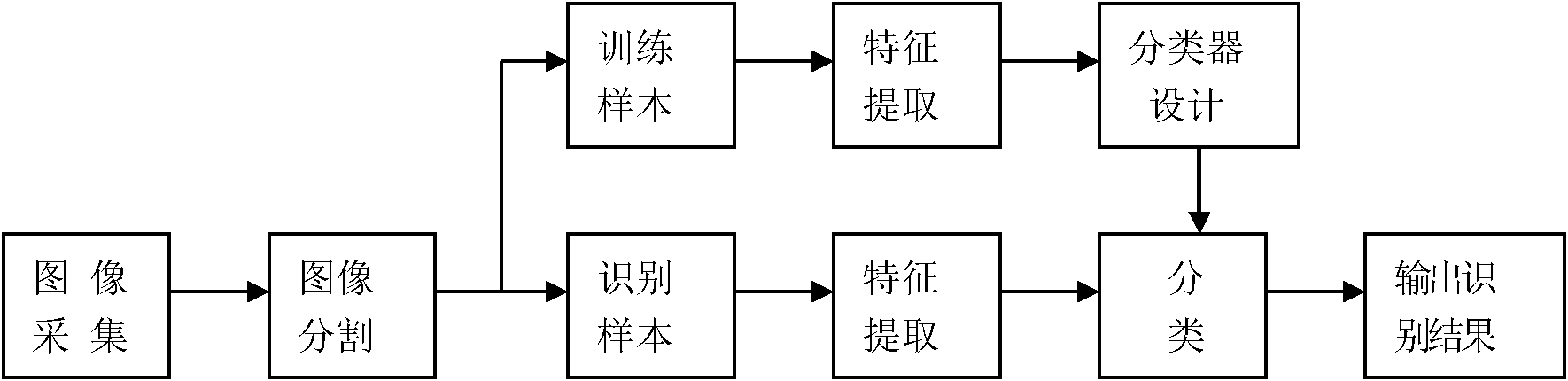

Method used

Image

Examples

Embodiment

[0052] A total of 100 images of typical defects collected by the camera, mainly including broken edges, holes, folds, grass fibers and some relatively rare defects, were tested and analyzed with 100 images without defects. Such as Figure 4 Shown in are images with various paper defects and images without defects. A certain number of defective images and non-defective images are randomly selected from the above images as training samples for training, and the rest are used as test samples for training and identification based on the SVM method. The overall test results are shown in Table 1. In order to highlight the superiority of this algorithm In order to improve the performance, artificial neural network algorithm was used to test under the same conditions, and the results are shown in Table 2. At the same time, the kernel parameters of the SVM algorithm are changed, and the corresponding results are shown in Table 3.

[0053] Experimental steps:

[0054] Step 1, use thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com