Method and assembling device for assembling and disassembling stator and rotor of permanent magnet synchronous motor

A permanent magnet synchronous motor, stator and rotor technology, applied in electromechanical devices, electric components, manufacturing motor generators, etc., can solve the problems of unsafe operation of workers, difficulty in ensuring production efficiency and product quality, uncontrollable speed of stator and rotor, etc. , to achieve the effect of convenient operation, simple structure and low cost

Active Publication Date: 2011-06-15

襄阳中车电机技术有限公司 +1

View PDF5 Cites 32 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to aim at the attraction of the existing permanent magnet synchronous motor when the stator and rotor are combined and disassembled, which will cause the relative movement speed of the stator and rotor during the disassembly and assembly process of the permanent magnet synchronous motor to be uncontrollable and unsafe for workers to operate. At the same time, the production efficiency and The problem of product quality is also difficult to guarantee. A permanent magnet synchronous motor is proposed. When the permanent magnet synchronous motor is assembled, the permanent magnet synchronous motor is dismantled and assembled. Guaranteed permanent magnet synchronous motor stator and rotor combination, disassembly method and assembly device

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

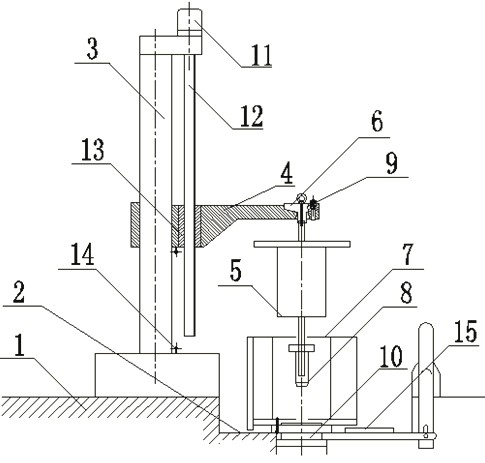

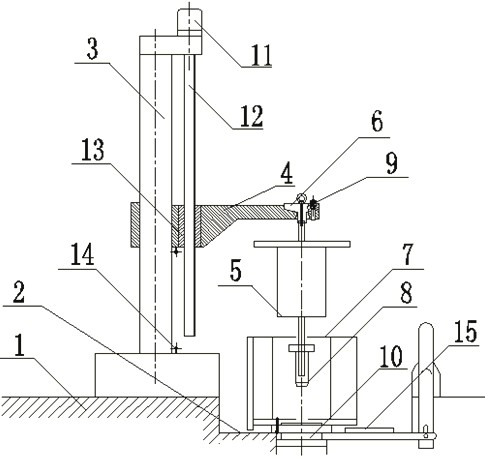

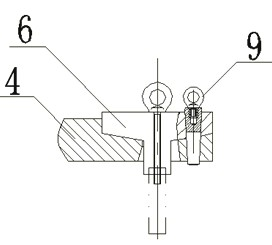

The invention provides a method and assembling device for assembling and disassembling a stator and a rotor of a permanent magnet synchronous motor. The method is characterized by adopting a rocker arm vertical permanent magnet synchronous motor stator and rotor assembling and disassembling method to fix a rotor on a rocker arm by a floating positioning seat, with the excircle and end face at the shaft extension end or the excircle and end face at the extension end of the rotor as the positioning surfaces, plugging a tapered positioning pin after the floating positioning seat is fixedly positioned, ensuring the axis of the rotor to be vertical to the horizontal plane and on the same straight line with the center line of a stator and arranging a pilot rod at the front end of the rotor; fixing the stator on a stator positioning disc by a bolt, with a bearing chamber at the end where the end cover is assembled and the end face of the bearing chamber as the positioning surfaces; installing the stator positioning disc on which the stator is installed in the center of a stator fixing station and ensuring the central axis of the stator to be vertical to the horizontal plane and coaxial with the floating positioning seat of the rotor; installing the rocker arm on a column, driving the rocker arm to move up and down via a screw drive mechanism and driving the rotor installed on the rocker arm to move up and down together when the rocker arm moves up and down to realize assembly and disassembly of the stator and the rotor of the permanent magnet synchronous motor.

Description

Permanent magnet synchronous motor stator and rotor assembly and disassembly method and assembly device technical field The invention relates to an assembly method and device of motor components, in particular to a vertical assembly of a large-power permanent magnet synchronous motor stator and rotor to overcome the magnetic field attraction of a permanent magnet and ensure controllable assembly speed and position of the stator and rotor assembly The method and device, especially when the stator and rotor of the permanent magnet synchronous motor with a larger power of 30KW or more are vertically or horizontally assembled or disassembled, the attraction force cannot be controlled manually. Background technique With the development of motor control technology, AC asynchronous motors are widely used because of their simple structure, reliable operation, long life, low cost and easy maintenance. However, compared with DC motors, it has poor speed regulation performance, small...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H02K15/00H02K15/16

Inventor 黄谷香肖波罗先忠田奎森李锟肖军年

Owner 襄阳中车电机技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com