Welded-type rear cover of automobile through axle housing

A welding type, axle housing technology, applied in the directions of axles, wheels, vehicle parts, etc., can solve the problems of not easy to weld to the through axle housing, poor weldability of the rear cover, easy to open welding, etc., to achieve light weight, good weldability, The effect of not easy to leak oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

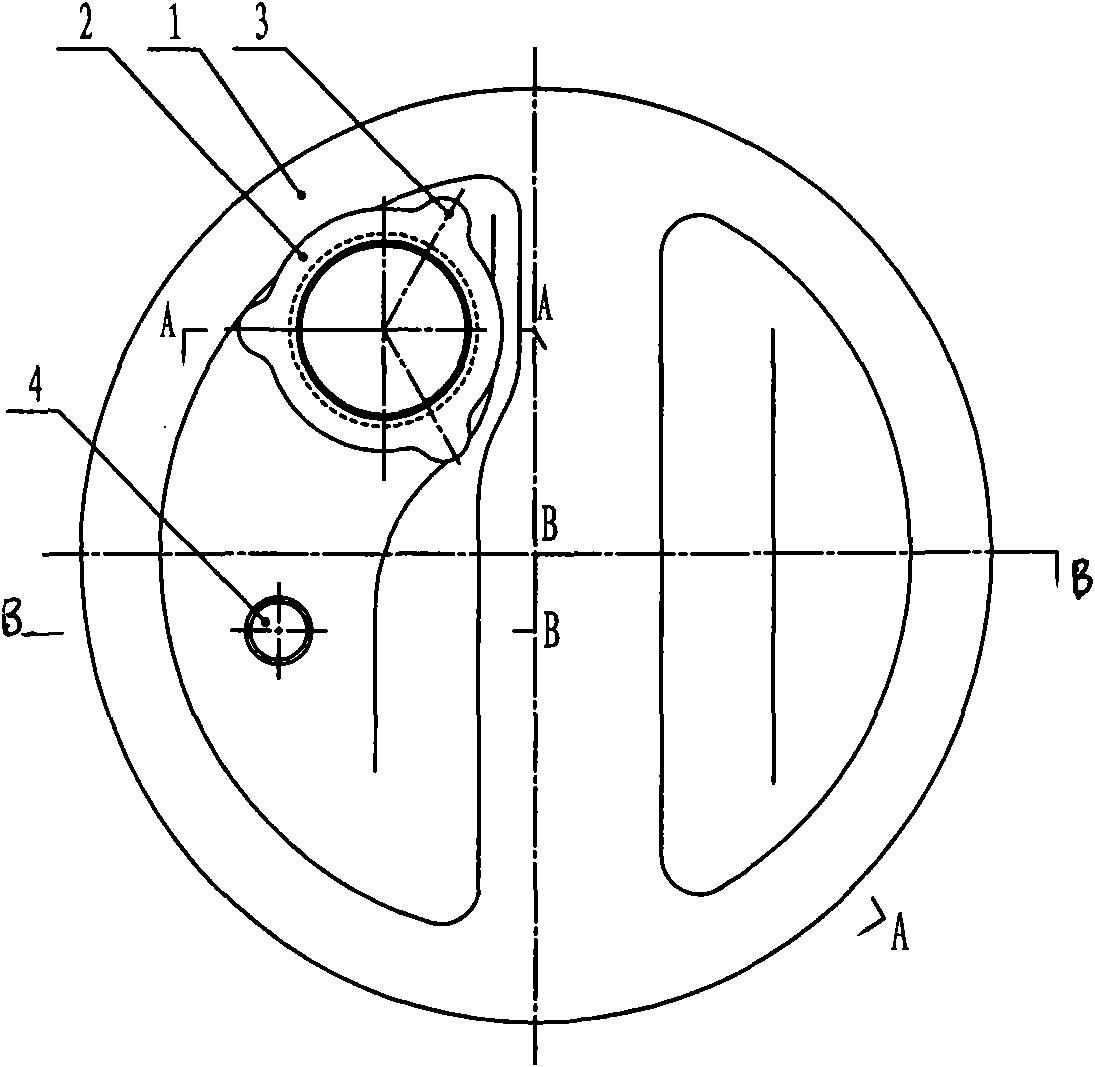

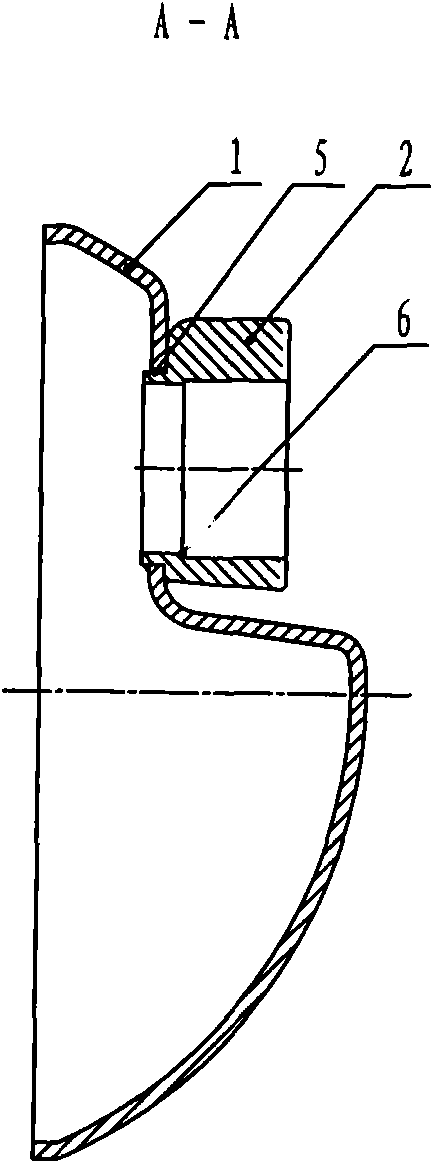

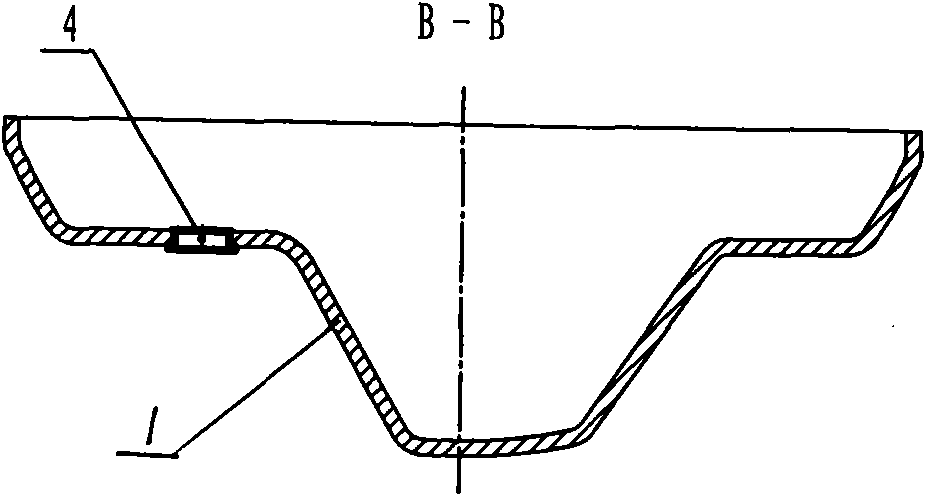

[0012] From Figure 1-Figure 3 It can be seen from the figure that: a welded rear cover of automobile through-axle casing is characterized in that: the welded rear cover of automobile through-axle casing is mainly formed by welding a cover body 1 and a connecting seat 2, and the cover body 1 is in the form of The cavity is in the shape of a circular basin, and the cover body 1 can be a steel stamping part. The middle part of the front surface of the cover body 1 is to the right of a vertical frustum-shaped protrusion, and the left and right parts of the front surface of the cover body 1 are both It is an arc-shaped plane, and a seat hole 5 is set on the upper part of the left arc-shaped plane of the cover body 1, which is used for welding the connecting seat 2, and an oil hole 4 with internal thread is set on the lower part of the left arc-shaped plane of the cover body 1 , for screwing the oil drain plug, welding the connecting seat 2 in the seat hole 5 on the cover body 1, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com