Horizontal damping device for landing gear

A shock absorber, landing gear technology, applied in landing gear, transportation and packaging, aircraft parts, etc., can solve the problems of inability to use initial pressure, poor sealing performance of shock absorbers, aircraft vibration damage, etc., to reduce vibration damage , the effect of reducing the bending moment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

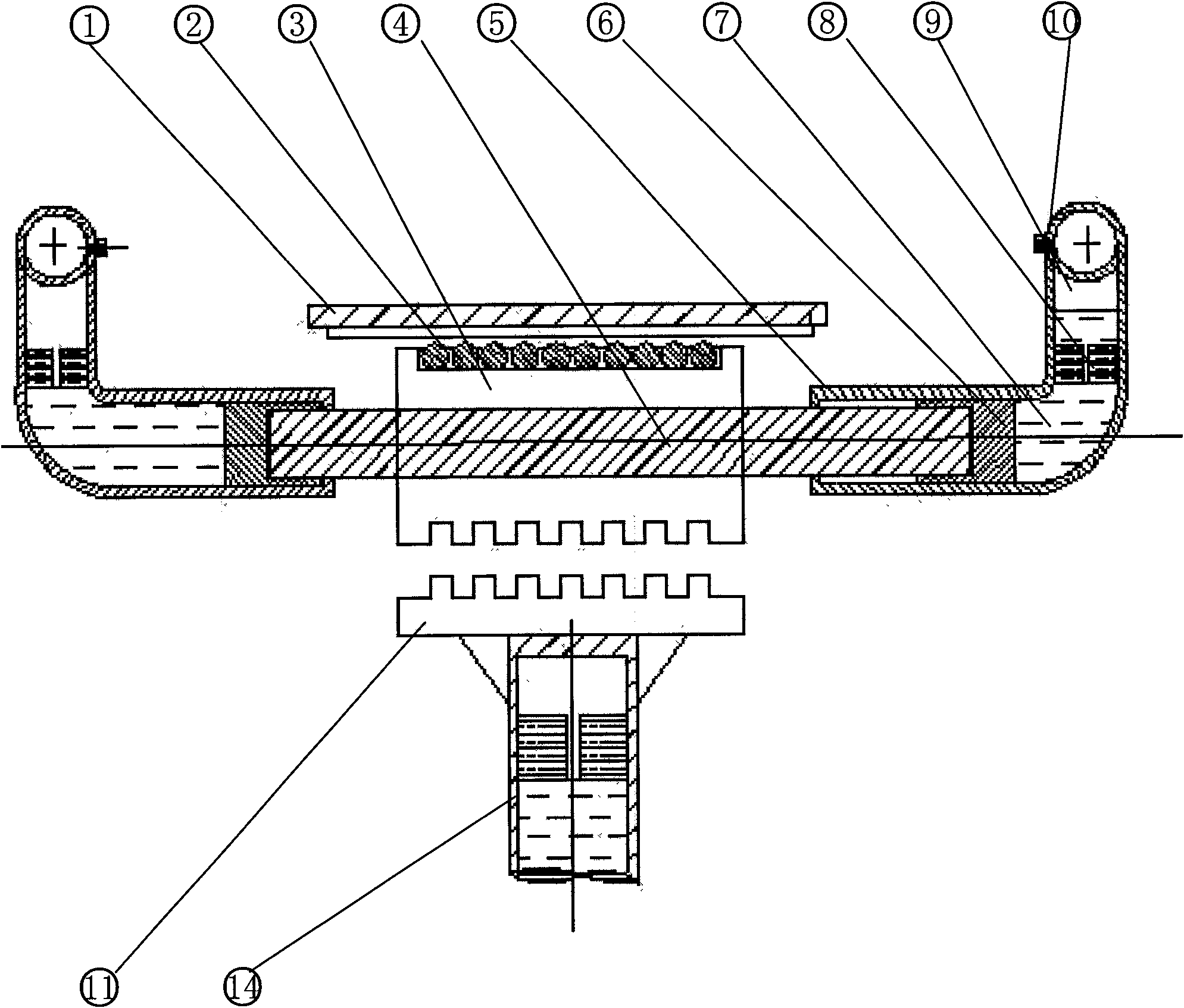

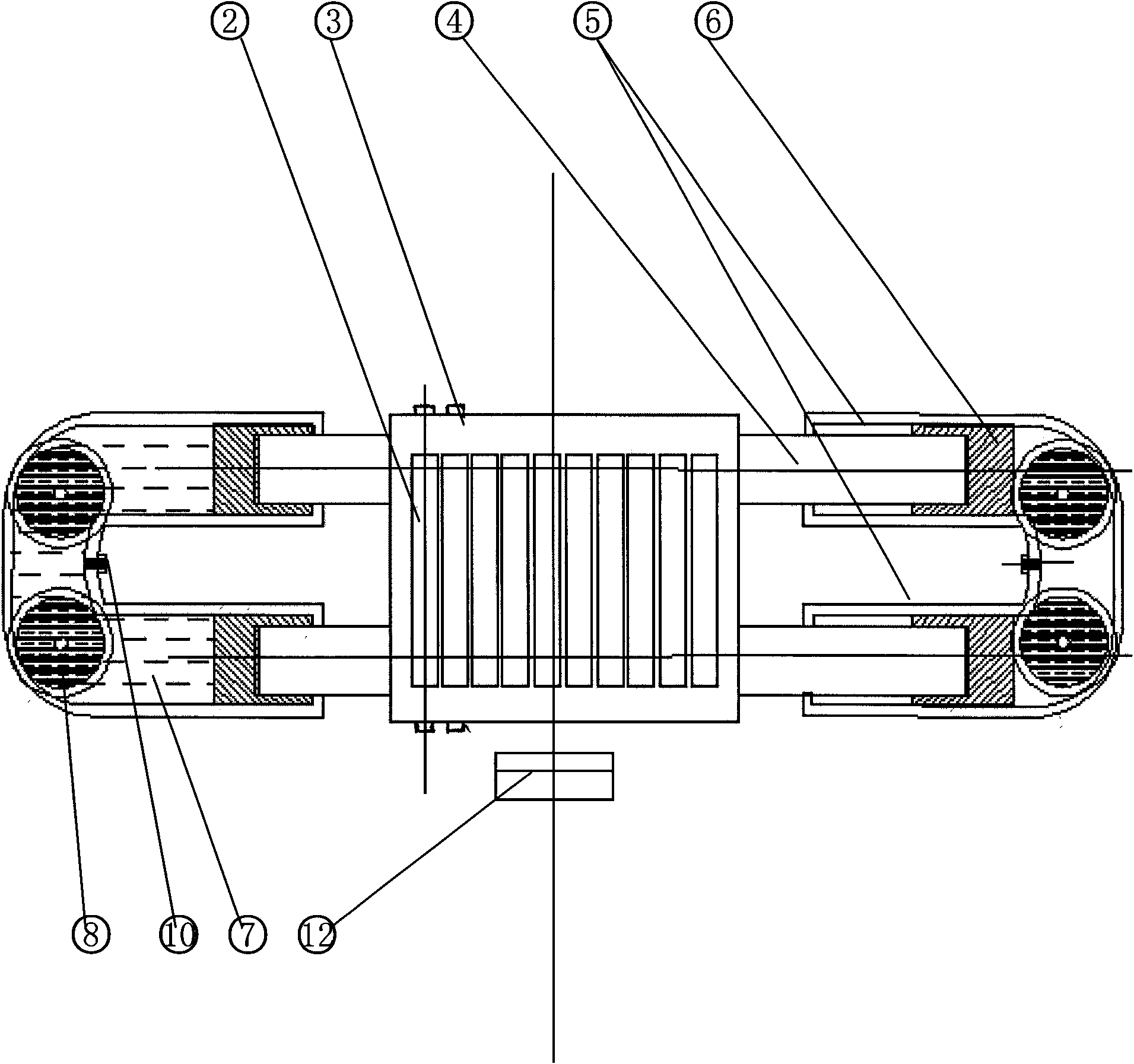

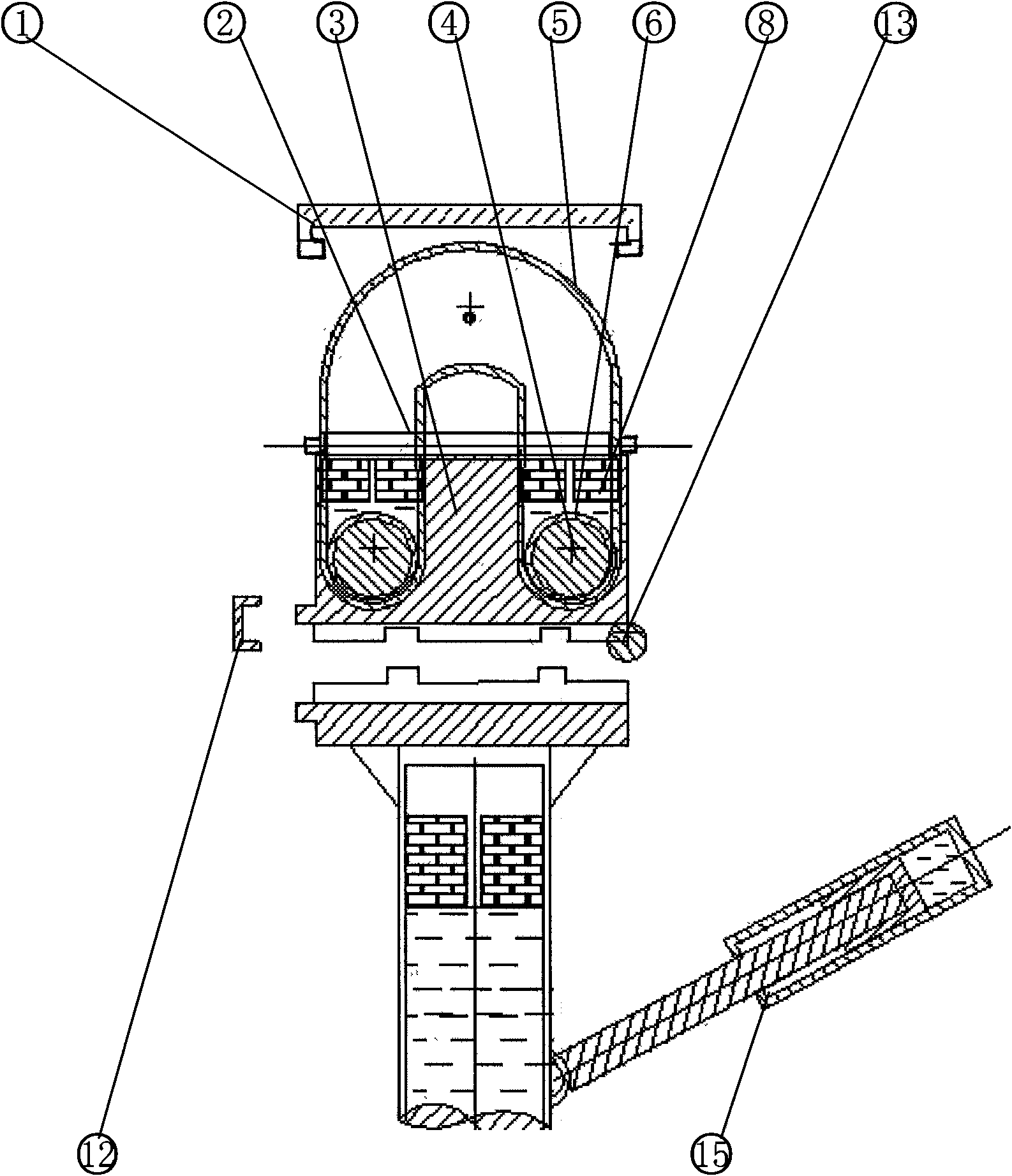

[0012] The top plate (1) is fixedly installed on the bottom of the fuselage, and there is a raceway on it for the movement of rolling elements. Ribs can withstand bidirectional axial loads and prevent the rollers from breaking away from the top plate; the rolling elements (2) are cylindrical rollers, and the diameter of both ends of the rollers arranged in the front is smaller than that of the tip in the middle or is converging conical. Installed in the groove on the top of the supporting frame (3), there are grooves for placing the rolling elements (2) on both sides of the groove, and a circular hole is opened in the groove, and the two ends of the cylindrical roller pass through the circular hole and extend into the top plate (1) In the concave rib, the support frame cannot be separated from the top plate, preventing the undercarriage from transmitting the torque to the shock absorber placed horizontally through the support frame (3); the top plate (1), the rolling body (2) a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com