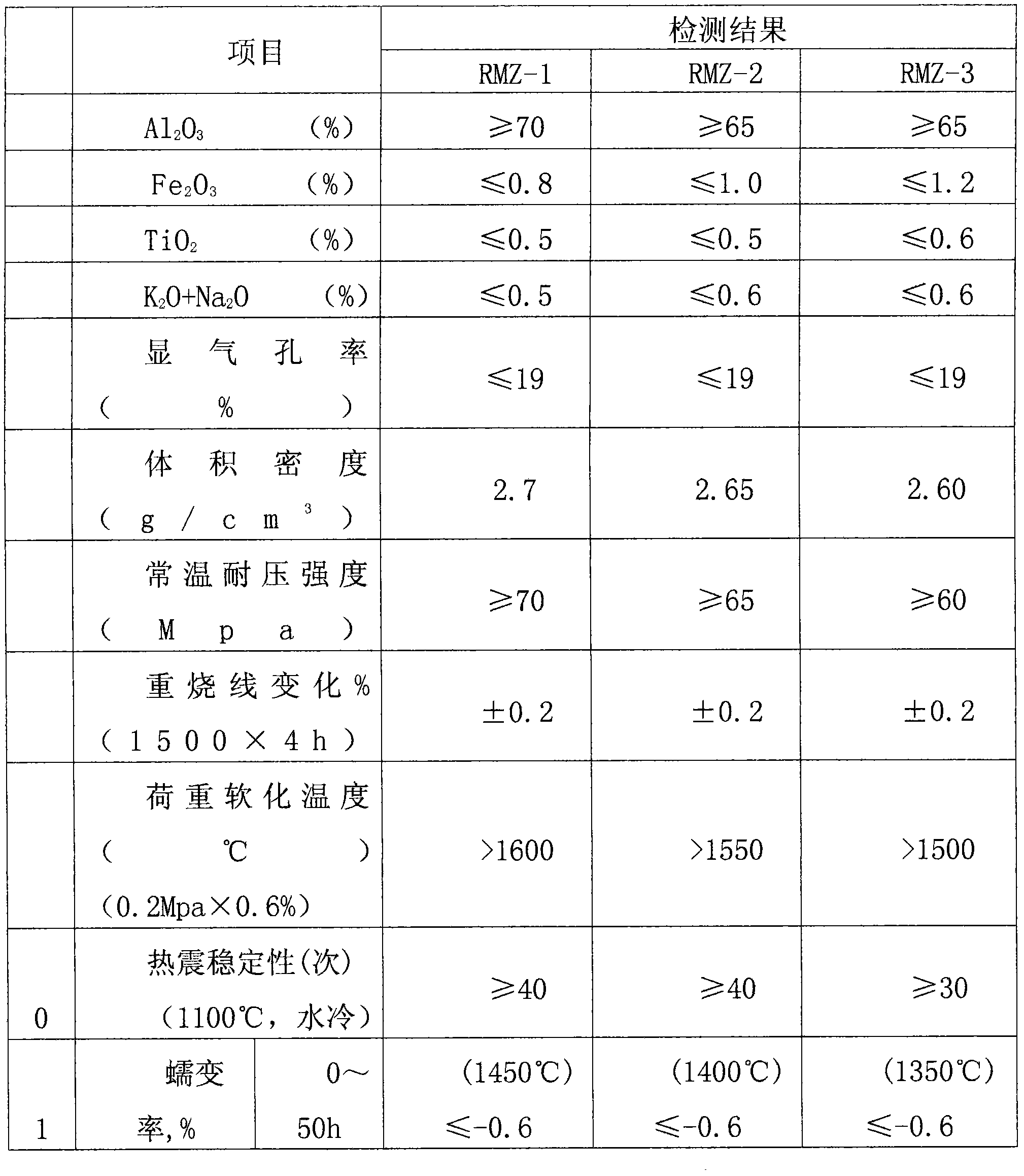

Tough mullite bricks for warm air ducts

A technology of hot air ducts and mullite bricks, applied in the field of refractory materials, can solve problems such as accidents, short life of hot air ducts, and easy redness, etc., to meet the requirements of longevity, good toughness, thermal volume stability, and resistance to CO erosion sex unaffected by the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the examples.

[0015] The technical solution adopted in the present invention is: a tough mullite brick for a hot air duct, which is calculated by weight: 5-40% of sintered mullite, 5-30% of sillimanite, 5-30% of andalusite, slab It is made of 5-30% corundum, 4-15% toughness additives and 3-10% bonded clay.

[0016] The preferred proportion by weight is: 30% of sintered mullite, 20% of sillimanite, 12% of andalusite, 20% of platy corundum, 10% of toughness additive and 8% of bonded clay. The thickness of the toughness additive is 1-10mm.

[0017] For the main raw materials, we use mullite and andalusite and other materials with high purity, creep resistance, thermal shock stability and stable linear change performance to control the index range of products to adapt to the working environment of pipeline lining; we introduce special additives In the high-temperature sintering reaction of the pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com