Turbine drilling tool bearing block having permanent magnet bearing

A technology of permanent magnetic bearings and turbodrilling tools, which is applied to drill pipes, drill pipes, earthwork drilling, etc., can solve problems such as overheating and wear, rolling elements prone to pitting and crushing, and bearing clearance cannot be guaranteed, etc., to achieve Low energy consumption, reduced number of trips and improved life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings.

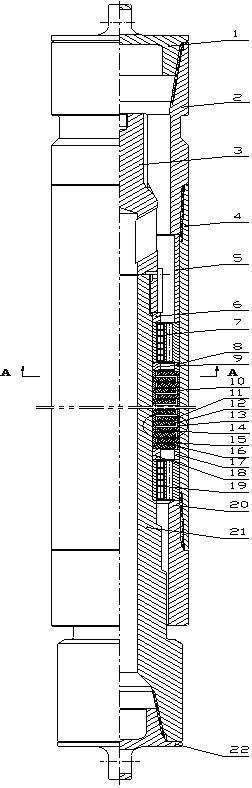

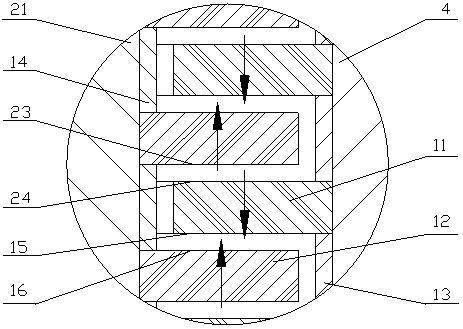

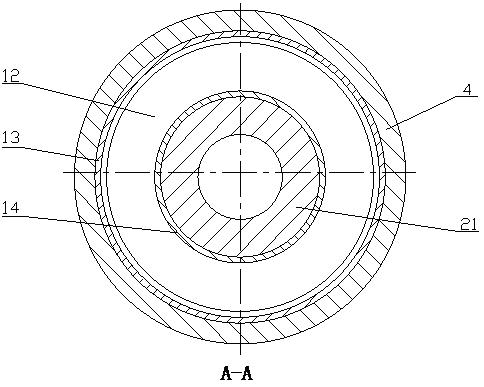

[0016] like figure 1 , figure 2 , image 3 As shown, a support section of a turbodrilling tool with a permanent magnetic bearing in the present invention is mainly composed of an upper joint 2, a connecting shaft 3, radial bearings (7, 19), a permanent magnetic bearing group 10, a lower short section 20, and a support section Shaft 21 and housing 4 constitute. The permanent magnetic bearing group 10 includes 15 to 25 pairs of permanent magnetic bearings, and the permanent magnetic bearing is composed of a fixed magnetic ring 11 , a moving magnetic ring 12 , an outer jacket 13 and a shaft sleeve 14 . The fixed magnetic ring 11 and the overcoat 13 are installed on the inner wall of the housing 4, the moving magnetic ring 12 and the shaft sleeve 14 are installed on the supporting joint shaft 21, and the moving magnetic ring 12, the fixed magnetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com