Driving device

A driving device and driven technology, applied in valve devices, engine components, machines/engines, etc., can solve the problem of ineffective control of engine intake and exhaust and combustion conditions, and inability to control the opening and closing phases of intake and exhaust valves and lift. , engine and lift characteristic curves are invariable, etc., to reduce assembly costs, improve reliability and stability, and reduce development costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

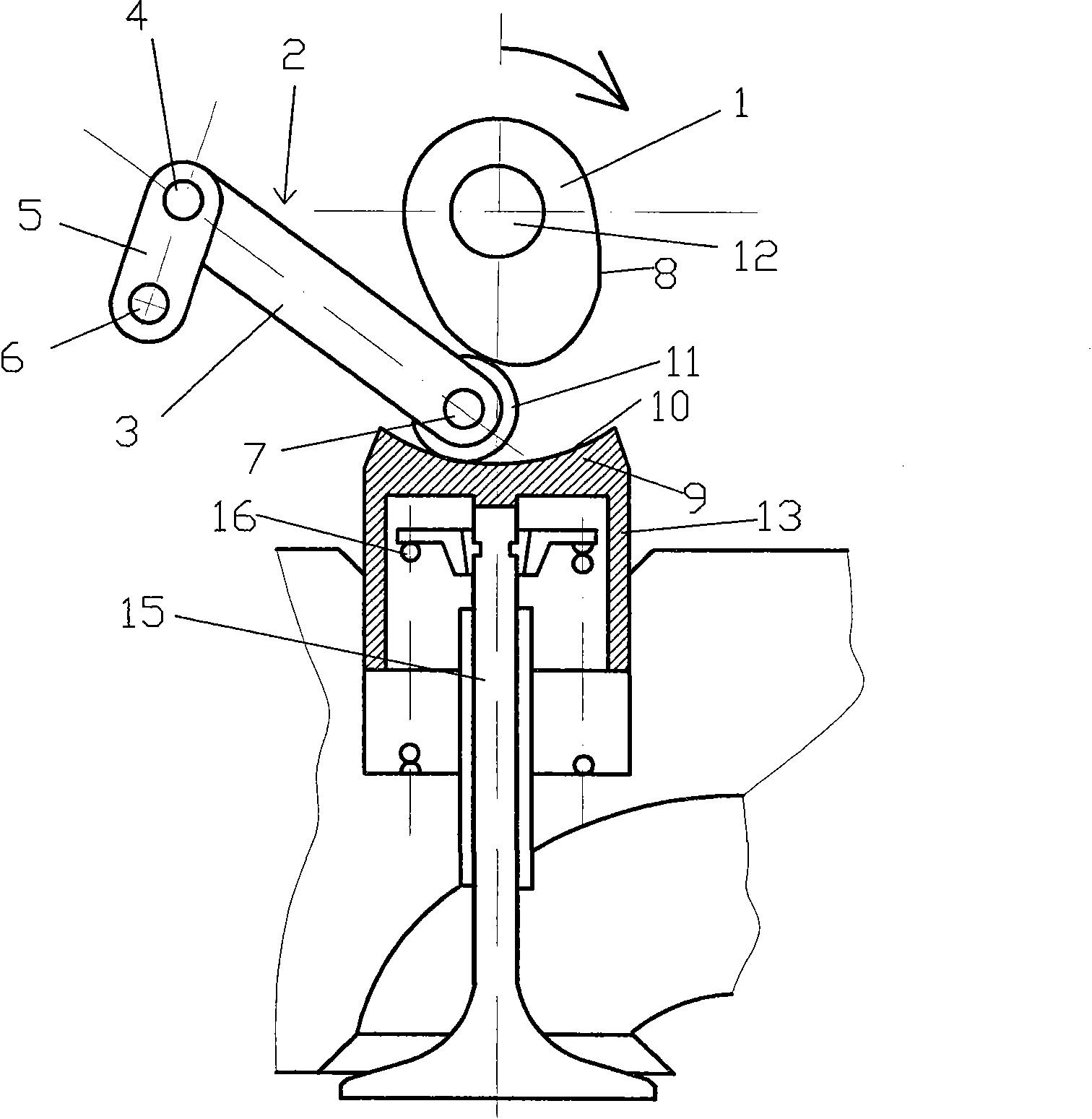

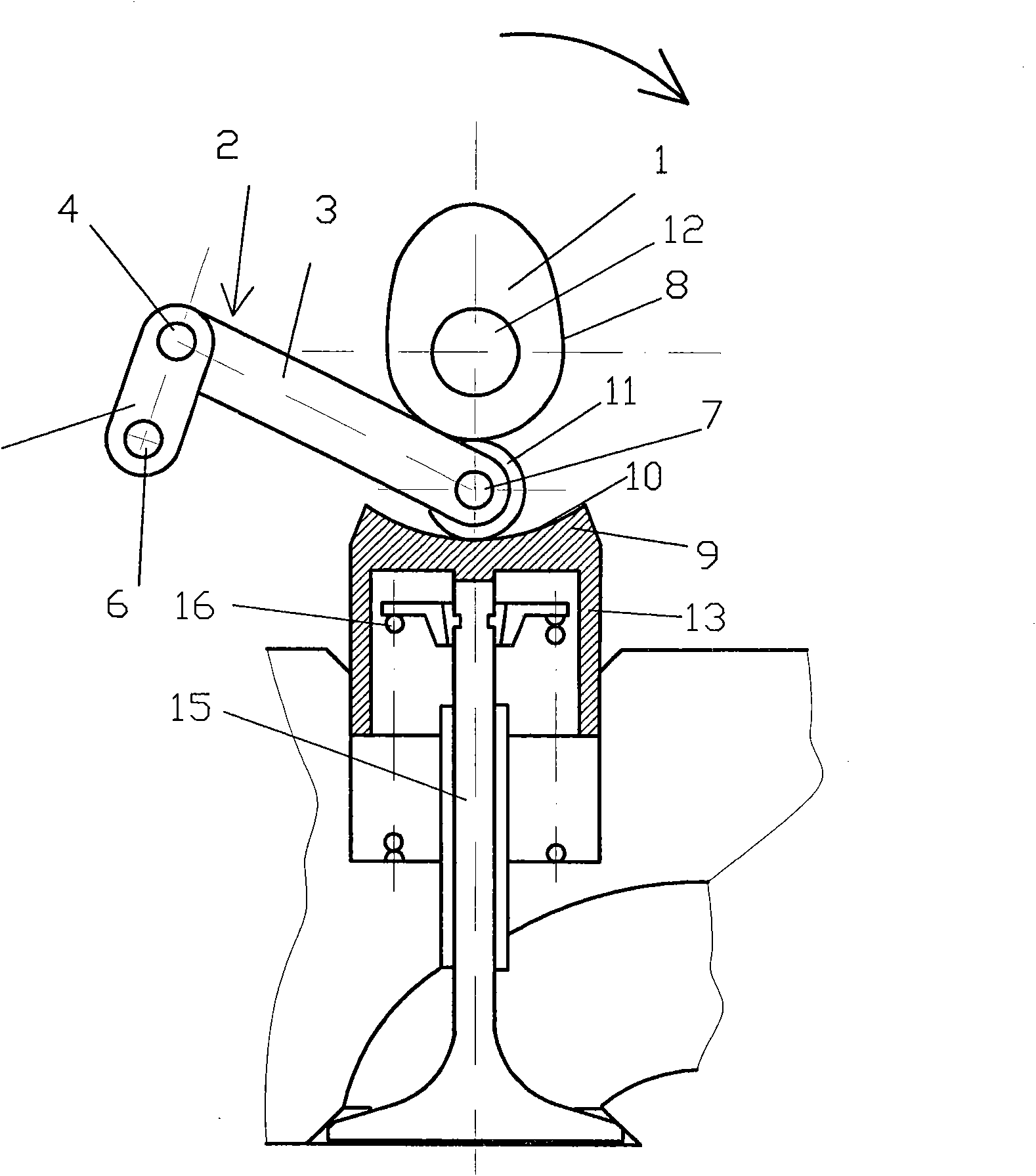

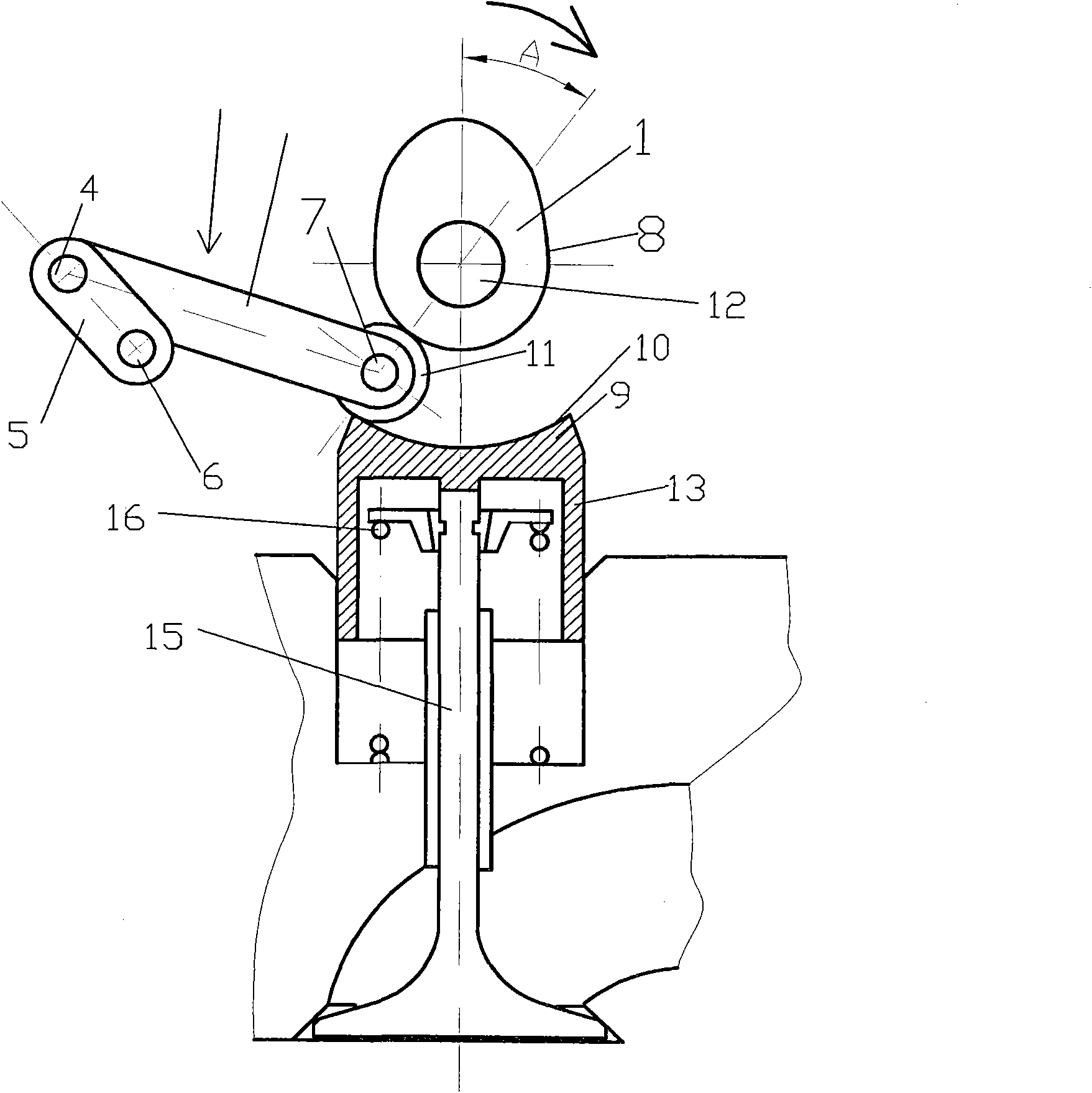

[0024] figure 1 A first embodiment of the drive device according to the invention is schematically represented. In this embodiment, the driving device drives the reciprocating motion of the engine cylinder valve stem.

[0025] Such as figure 1 As shown, the driving device has a cam 1 and a transmission mechanism 2 . The cam 1 is mounted on a camshaft 12 . The camshaft 12 is powered by a power unit not shown in the figure, thereby driving the cam 1 to rotate. The transmission mechanism 2 includes a connecting rod 3, a crank 5, a guide 9 and a roller 11, the connecting rod 3 and the crank 5 are rotatably connected by a pin 4, the crank 5 is hingedly supported on the drive shaft 6, and the guide 9 is located on the upper part of the tappet 13 and integrally formed with the cylinder valve tappet 13, its top surface has an arc surface 10, and the roller 11 is hingedly connected to the end of the connecting rod 3 close to the cam 1 and the guide 9 through the pin 7 , the roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com