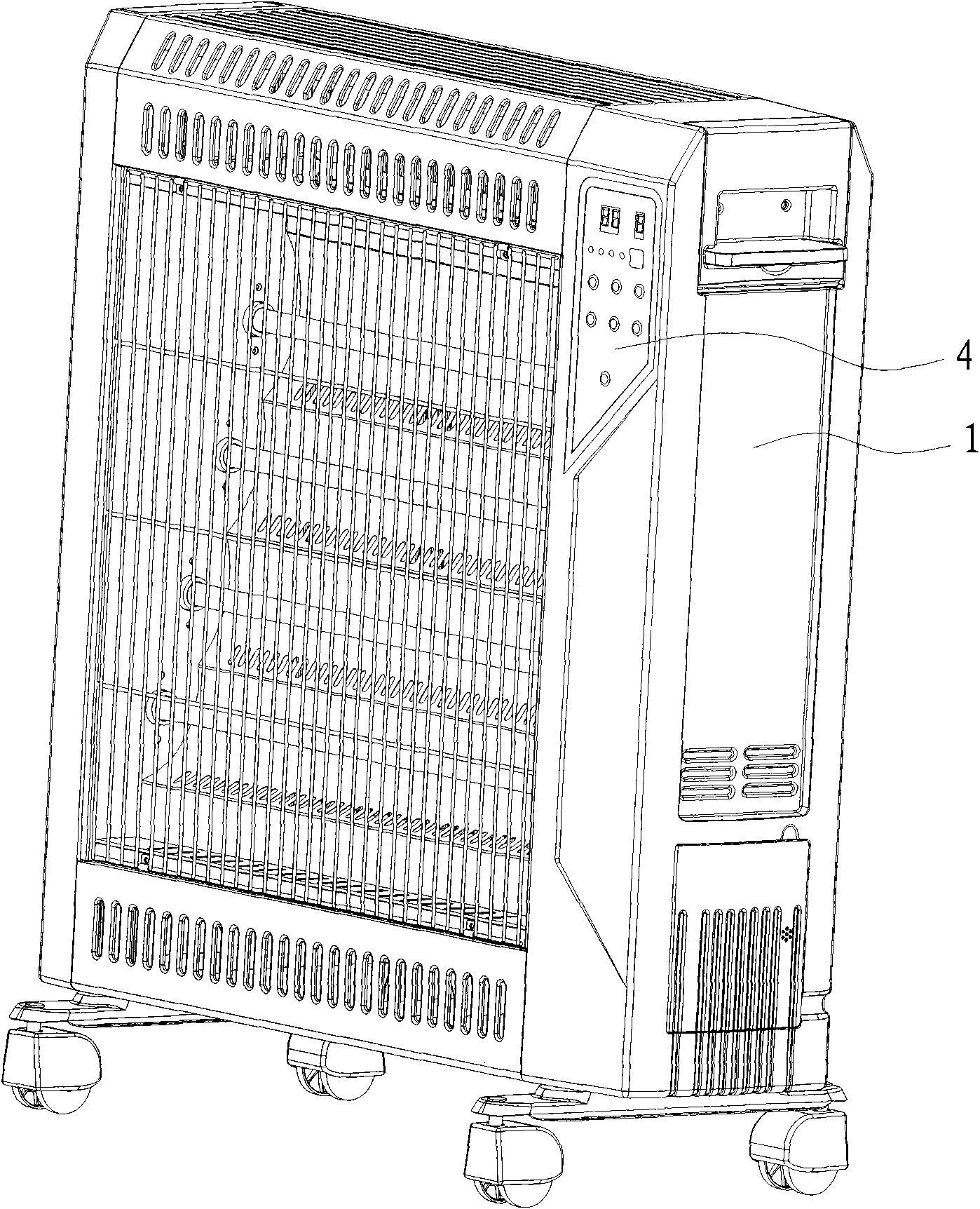

Circulating and reflecting electric heater

An electric heater and heat reflecting plate technology, applied in the field of electric heaters, can solve the problems of not being able to give full play to the effects of reflection and convection, no unified use of reflection and convection, unreasonable structural design, etc. The effect of increasing the area and improving the heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

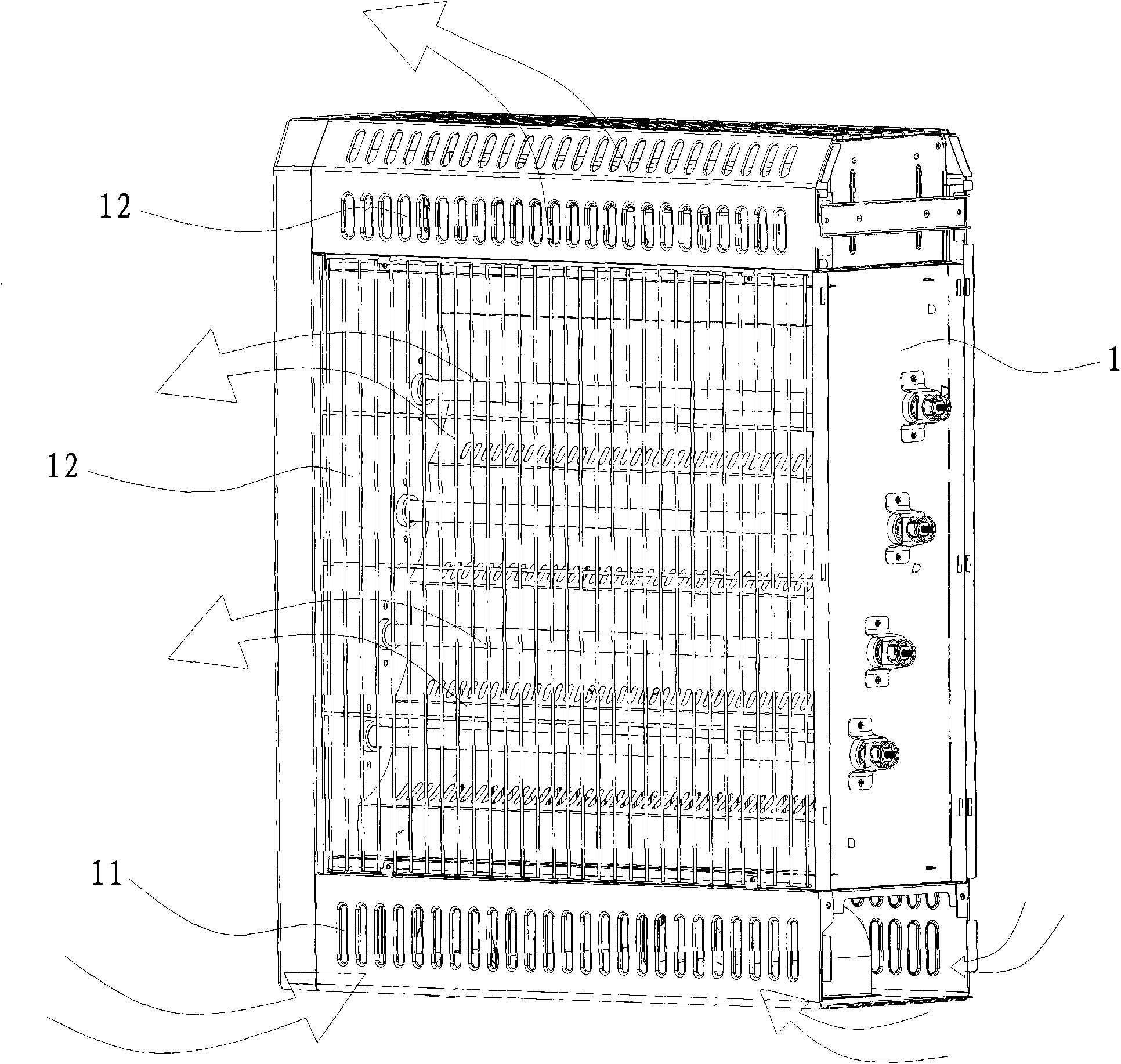

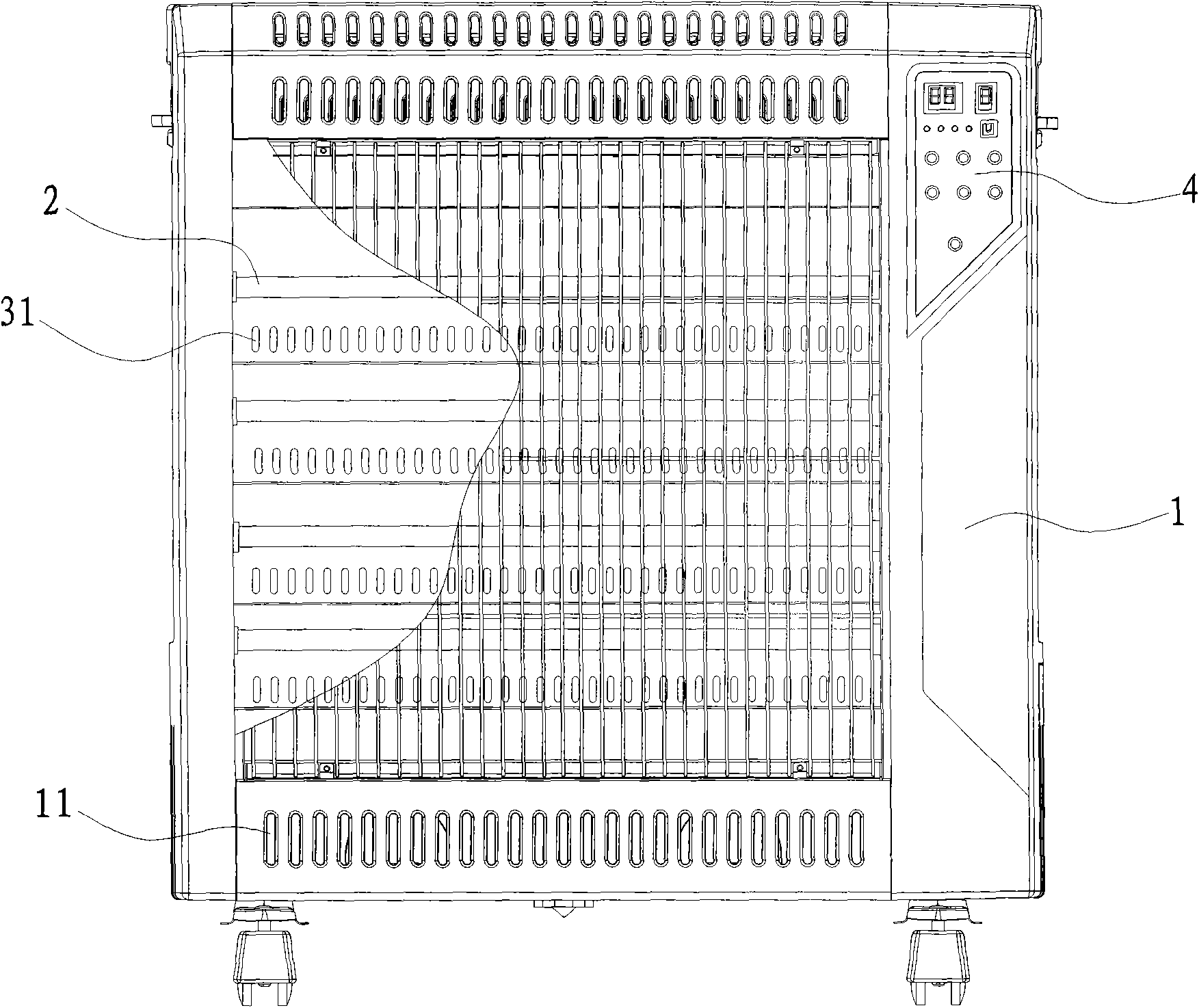

[0041] The second embodiment, compared to the first embodiment, such as Figure 7 As shown, the improvement mainly lies in that in the heat reflection plate 3, the shape of the reflection groove c is a right angle. The heating device 2 is located in the right-angle reflective groove c. The air flow hole 31 on the reflective groove c is located on the bottom edge of the right-angled reflective groove c. This right-angle reflective groove c can reflect heat from both horizontal and vertical directions, such as Figure 7 As shown, the reflected heat can be reflected from the upper air outlet 12 and the left side air outlet 12 of the casing 1 . Other parts are the same as those of the first embodiment, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vertical spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com