Device and method for controlling temperature and pressure of reactor of hypercritical water treatment system

A technology of treatment system and pressure control, applied in oxidation water/sewage treatment, non-electric variable control, control/regulation system, etc., can solve the problems of poor automatic regulation performance, affecting the reliable and long-lasting operation of the reactor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

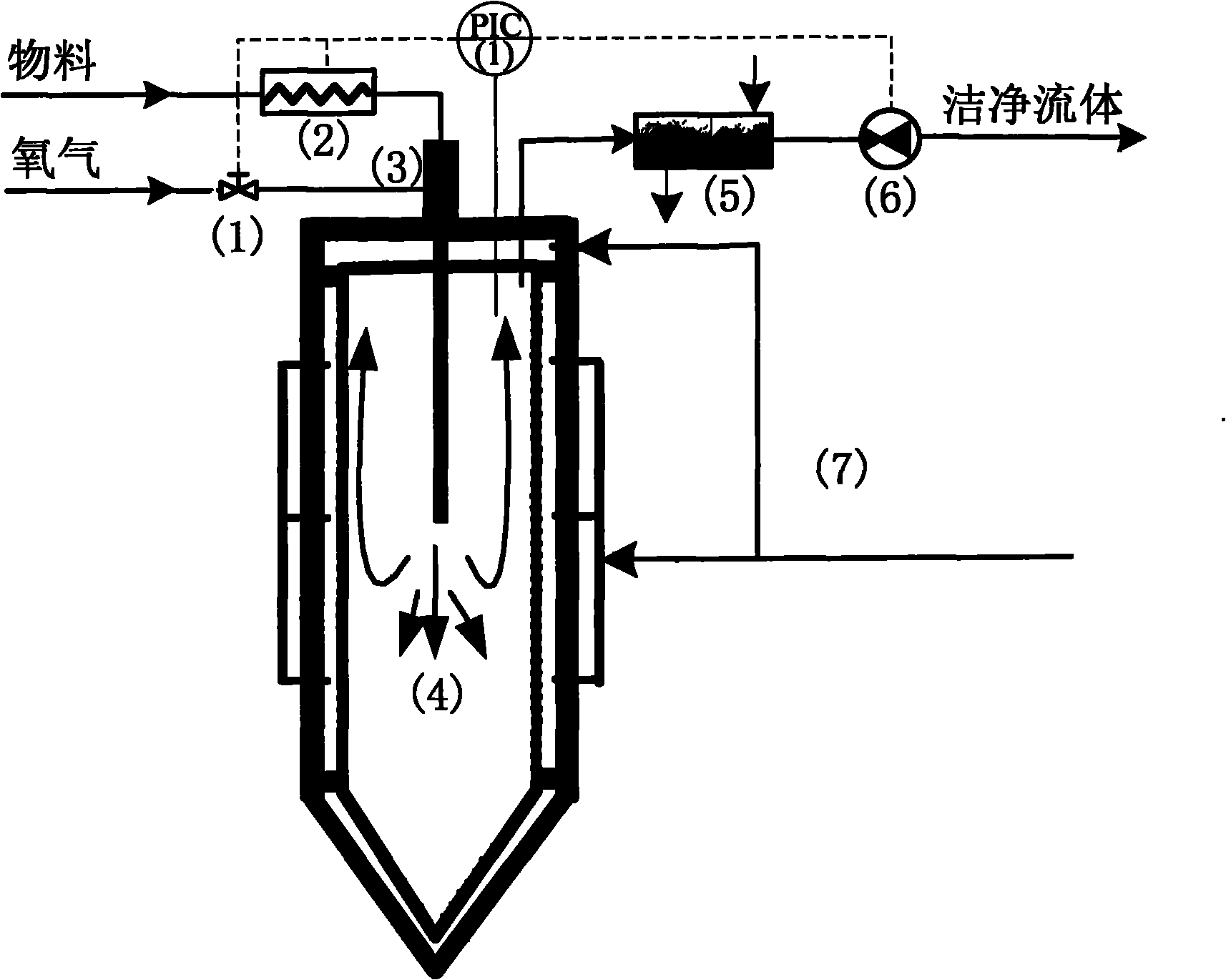

[0024] Such as figure 1 As shown, it is a schematic diagram of controlling the temperature and pressure of the fluid at the top of the supercritical water treatment reactor. 1 is an electric stop valve, 2 is an electric heater, 3 is a mixer, 4 is a reactor, 5 is a cooler, 6 is a back pressure valve, and 7 is evaporation wall water.

[0025] The working process of the supercritical water treatment reactor is as follows:

[0026] After being preheated by the heater 2, the waste organic material is fully mixed with oxygen in the mixer 3, and then enters the reactor 4 for desalination and reaction. Clean evaporation wall water enters the reactor 4 and forms a protective water film on the inner surface of the porous evaporation wall to avoid salt deposition and corrosion problems in the reactor. The reacted clean fluid flows out from the top outlet of the reactor 4, is cooled by the cooler 5 and depressurized by the back pressure valve 6, and then undergoes subsequent gas-liquid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com