Supercritical water processing control system and control method thereof

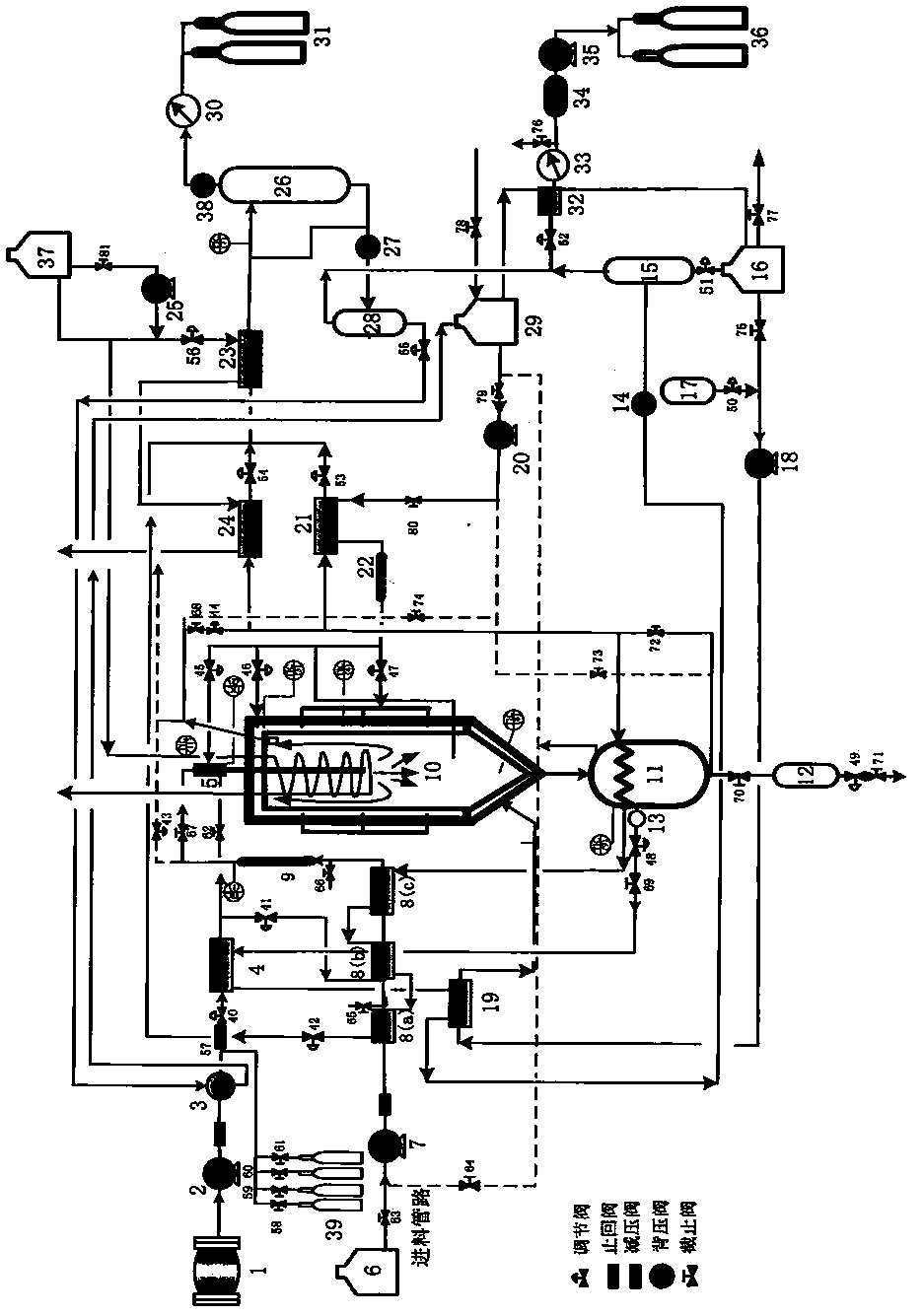

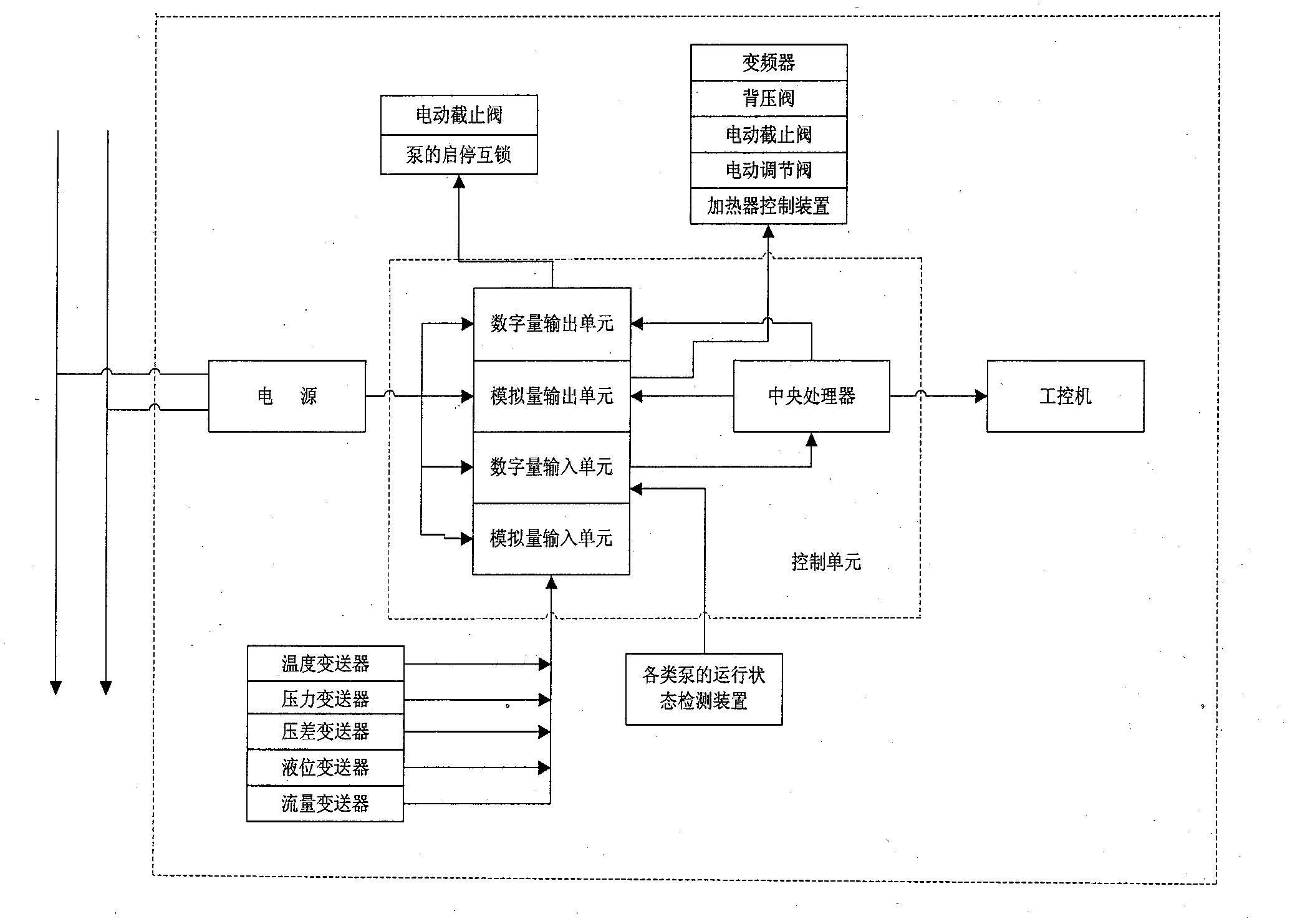

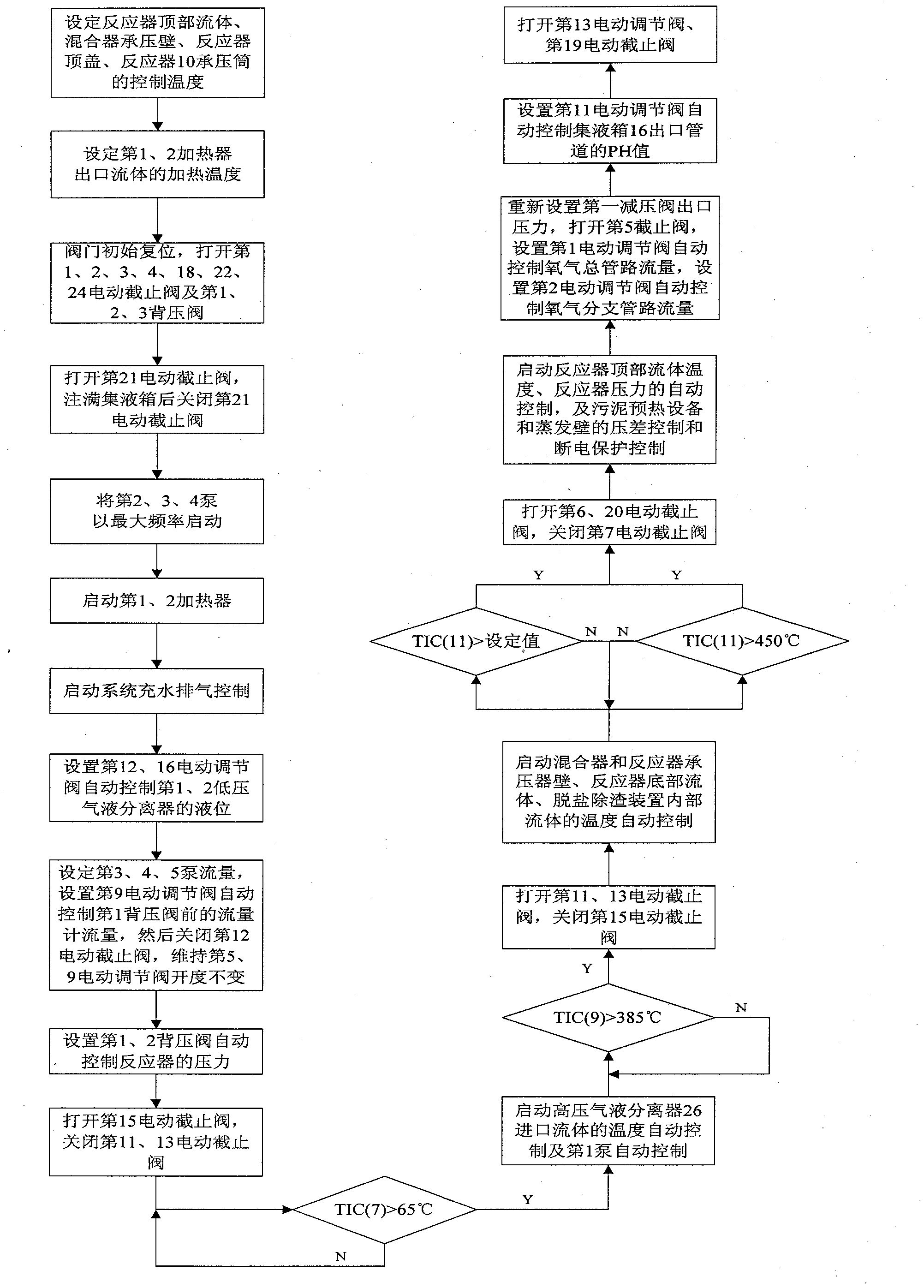

A technology of supercritical water and treatment control, applied in the direction of oxidized water/sewage treatment, comprehensive factory control, comprehensive factory control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0165] Example: I / O is at addresses 8 and 9 in the S7-400H CPU; addresses 10 and 11 are not used. Accessing L ID8 will cause the system to load the value DW#16#00000000 into the accumulator.

[0166] 4. Communication function

[0167] For programming device (PG) communication functions such as downloading and deleting blocks, one of the two CPUs must be selected even if the function affects the entire system on the redundant link. In redundant operation, data modified in one of the central processing units will affect other CPUs on the redundant link.

[0168] 5. The function of the synchronization module

[0169] The communication between two redundant S7-400H CPUs uses a synchronization module. Each CPU requires two synchronization modules, connected in pairs via fiber optic cables. The system supports hot-swappable synchronization modules, allowing users to participate in the maintenance of fault-tolerant systems and to control the failure of redundant connections witho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com