Methods of producing cross-linked polysaccharide particles

A technology of granules and polysaccharides, which is applied in the field of cross-linked polysaccharides and its preparation, and can solve problems such as yellowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0108] 1. Ca(OH) 2 Preparation of cross-linked guar gum

[0109]Water, QUAT 188 (3-chloro-2-hydroxypropyltrimethylammonium chloride), sodium hydroxide and guar chips were added to the TR-JE reactor and mixed. The mixture was then heated to 130°F and kept constant at 130°F for 1.5 hours. The guar splits were allowed to cool, washed for 3 minutes in a ratio of 10:1 (water:guar splits), filtered and collected.

[0110] A 25% aqueous solution of calcium hydroxide and deionized water were added to the wet soybean chips and mixed. A 65% solution of Quat 188 was slowly added to the mixture. One or more evacuation steps are performed. The mixture was then heated to 60°C for 1 hour. A 1% dispersion is available.

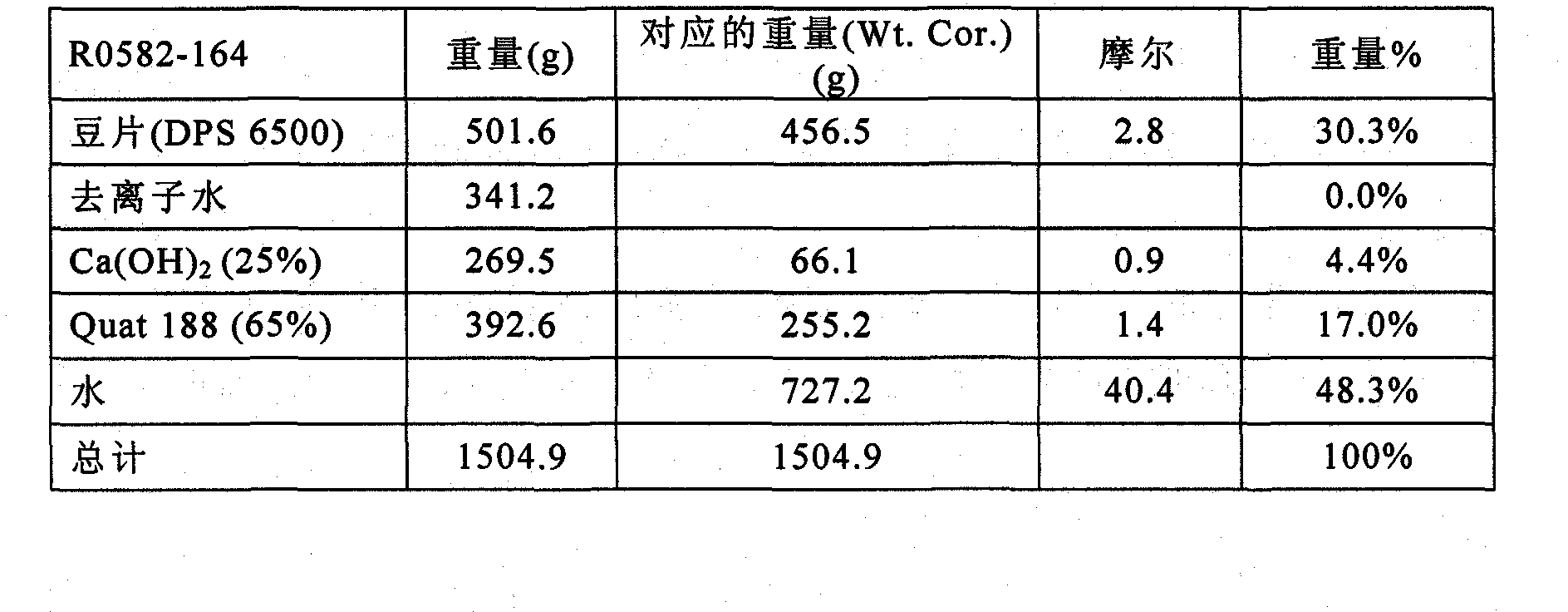

[0111] These flakes are then ground, usually using a flash mill, and an off-white powder is collected. The following is the feeding amount of sample R0582-164 (JAGUAR-17 type).

[0112] Table 1:

[0113]

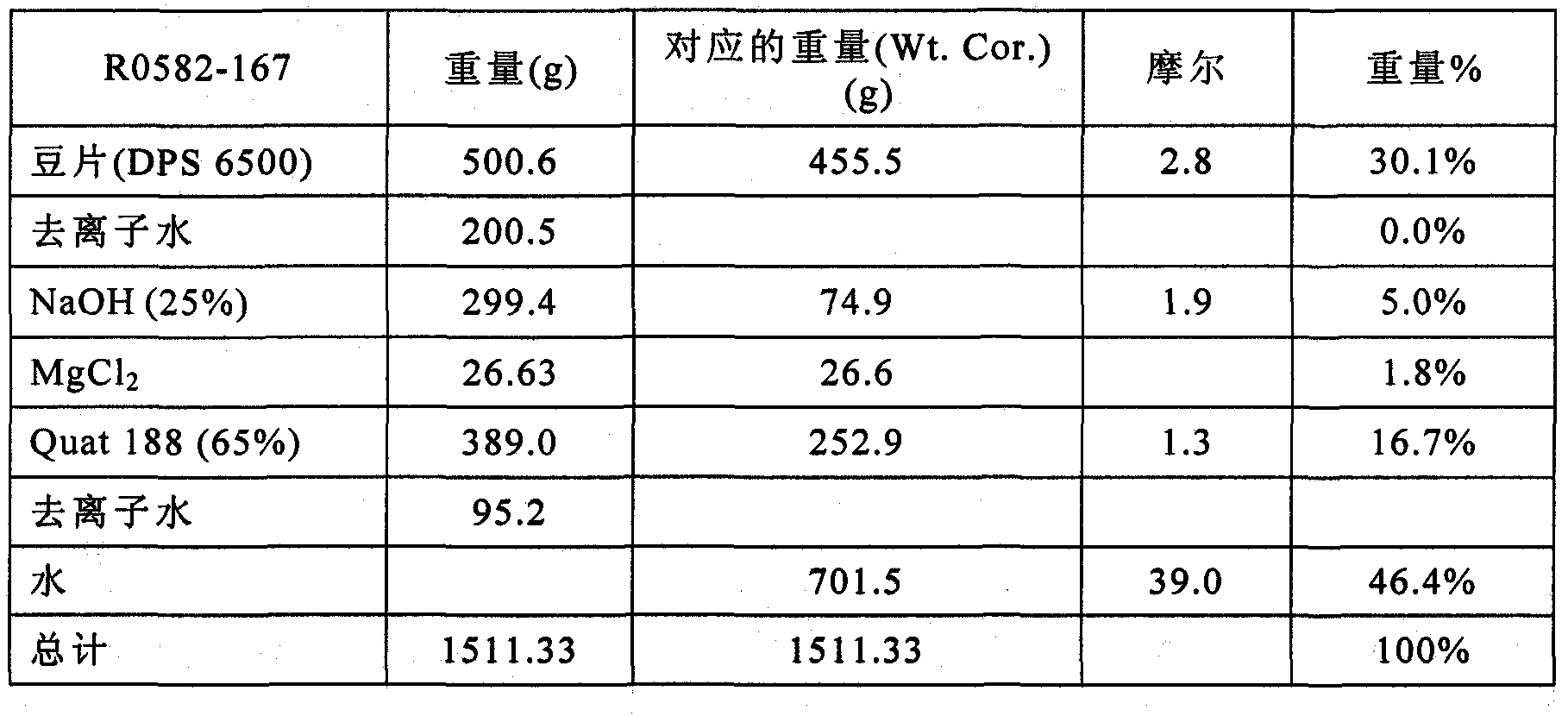

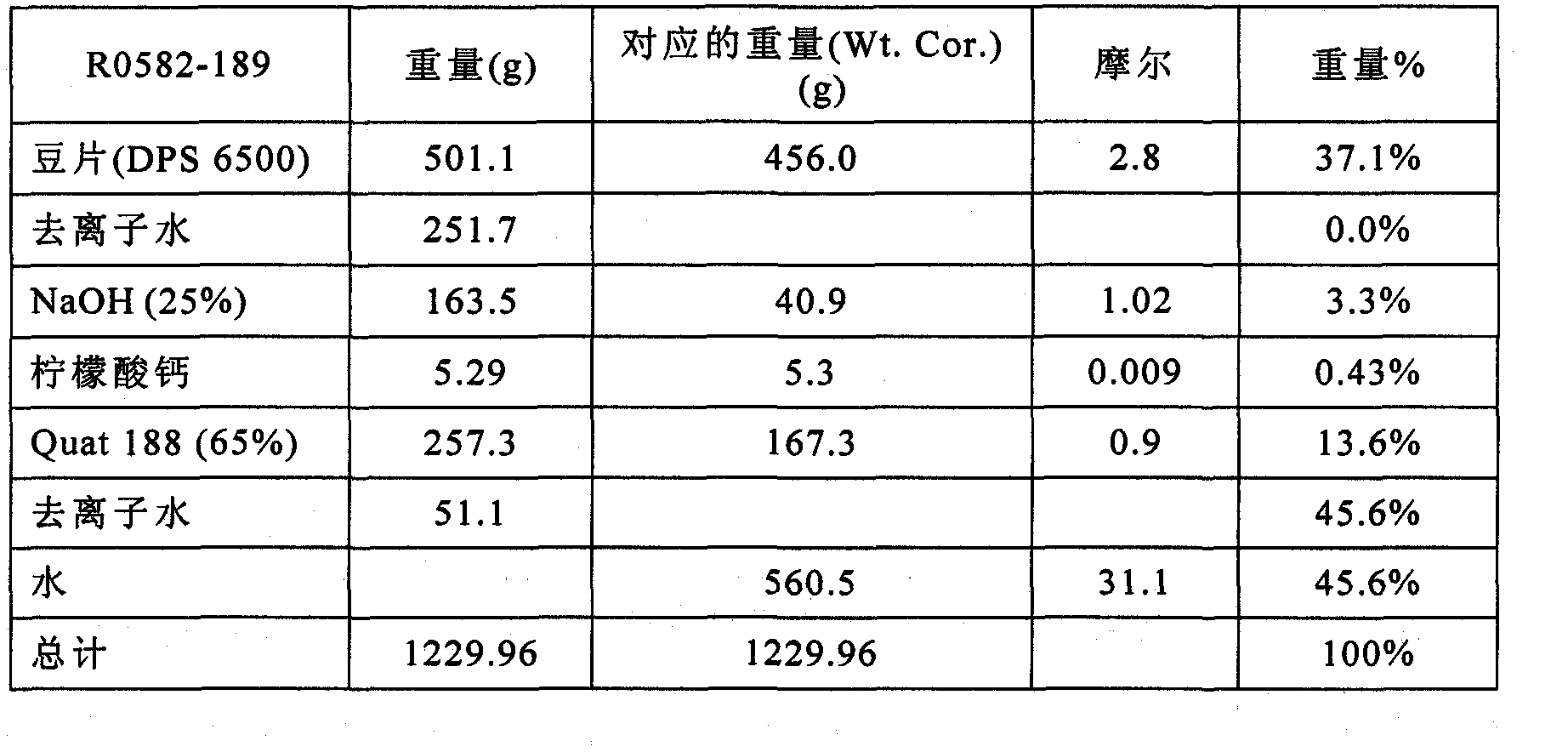

[0114] Table 2

[0115]

RxtrGel %M

1W%M ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com