Double-driving shaft composite automatic finishing method for blisk

A technology of finishing and integral blisk, applied in metal processing equipment, manufacturing tools, grinding/polishing equipment, etc., can solve problems such as limited technical effect, and achieve the effect of great social value and economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

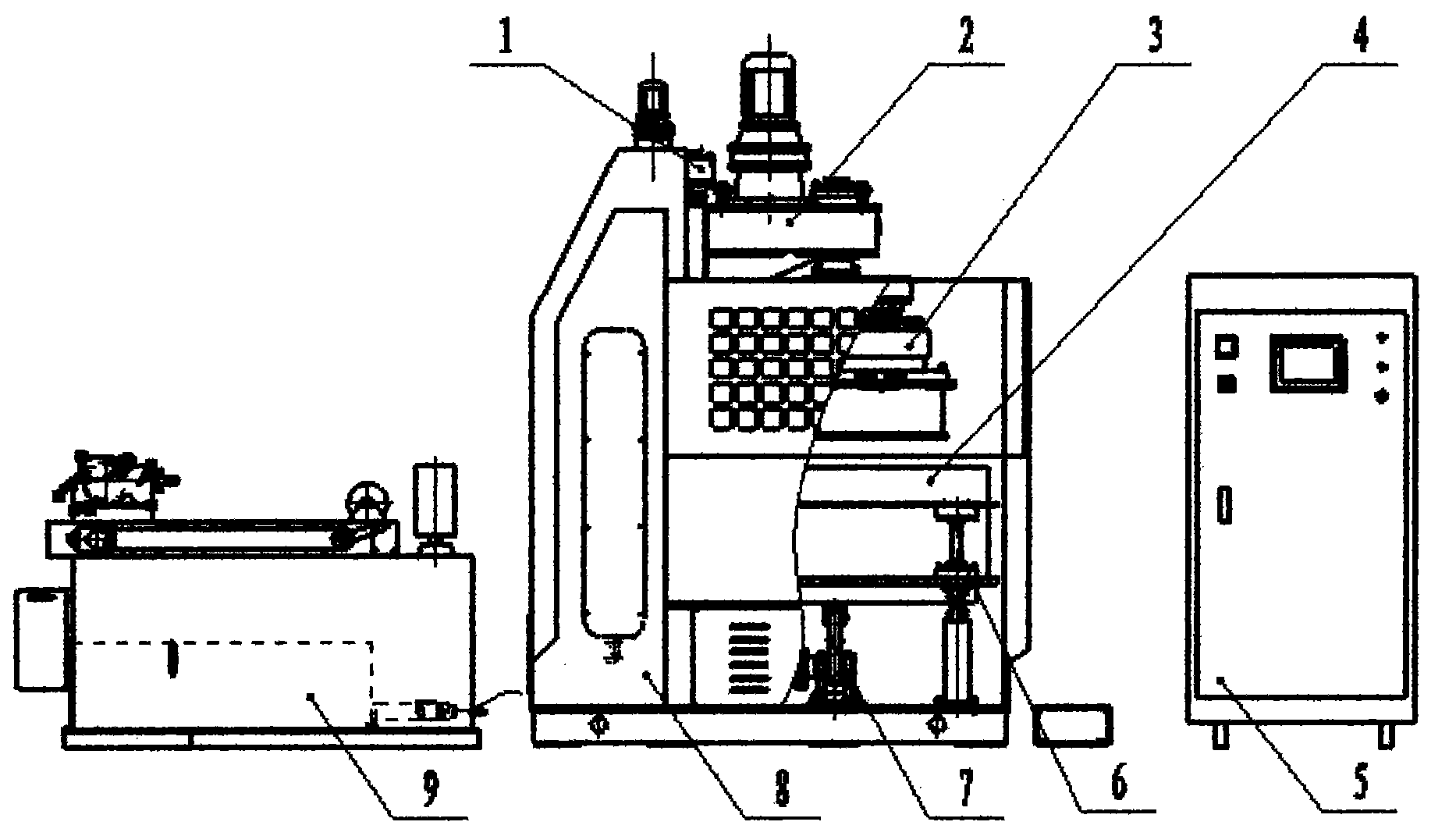

[0045] A compound automatic finishing method with dual drive shafts for integral blisks: use special equipment with a rotating table for processing; the special equipment with a rotating table has fixed rotating shafts; the double-driven blisks are The shaft composite automatic finishing processing method is specifically:

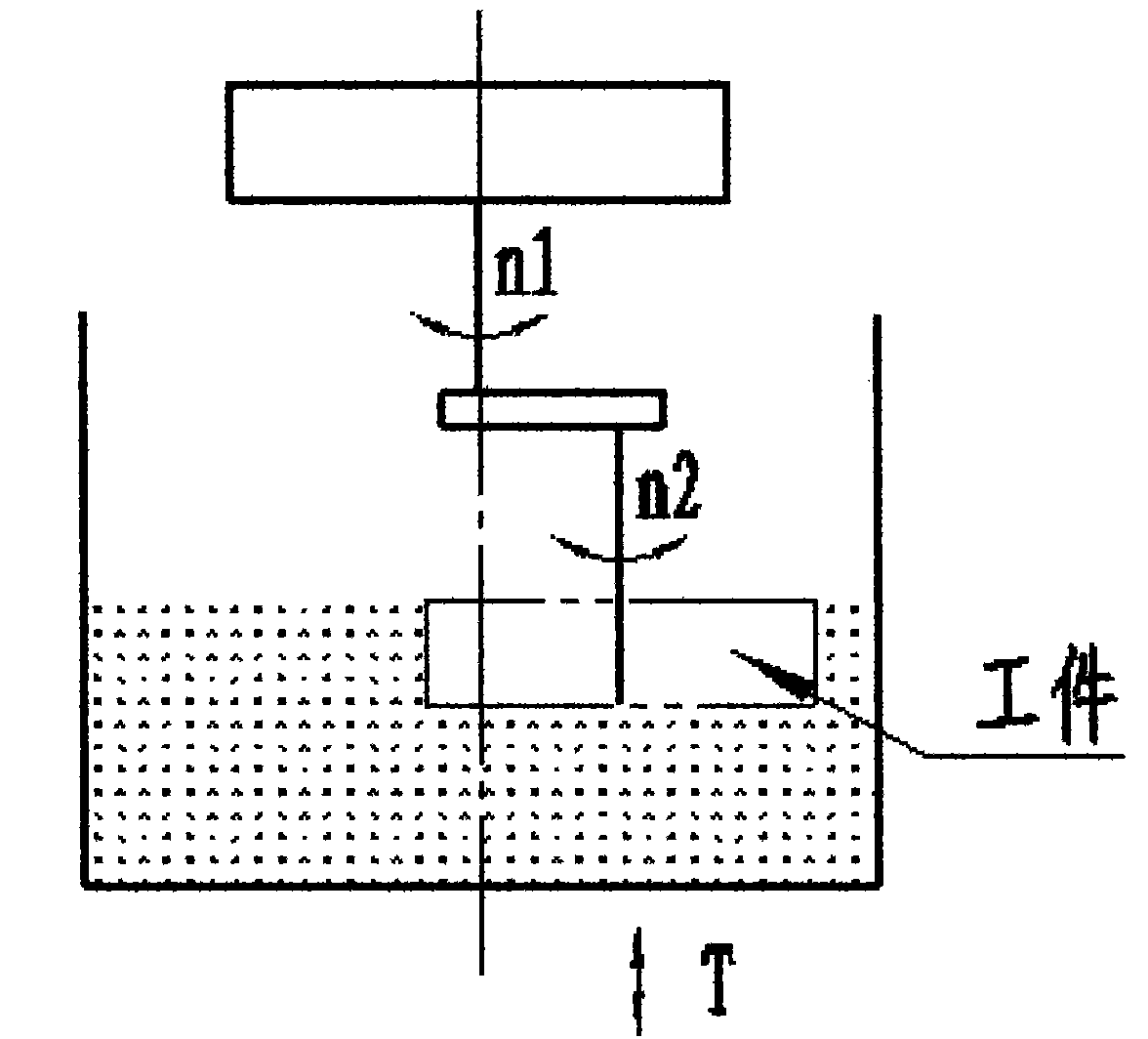

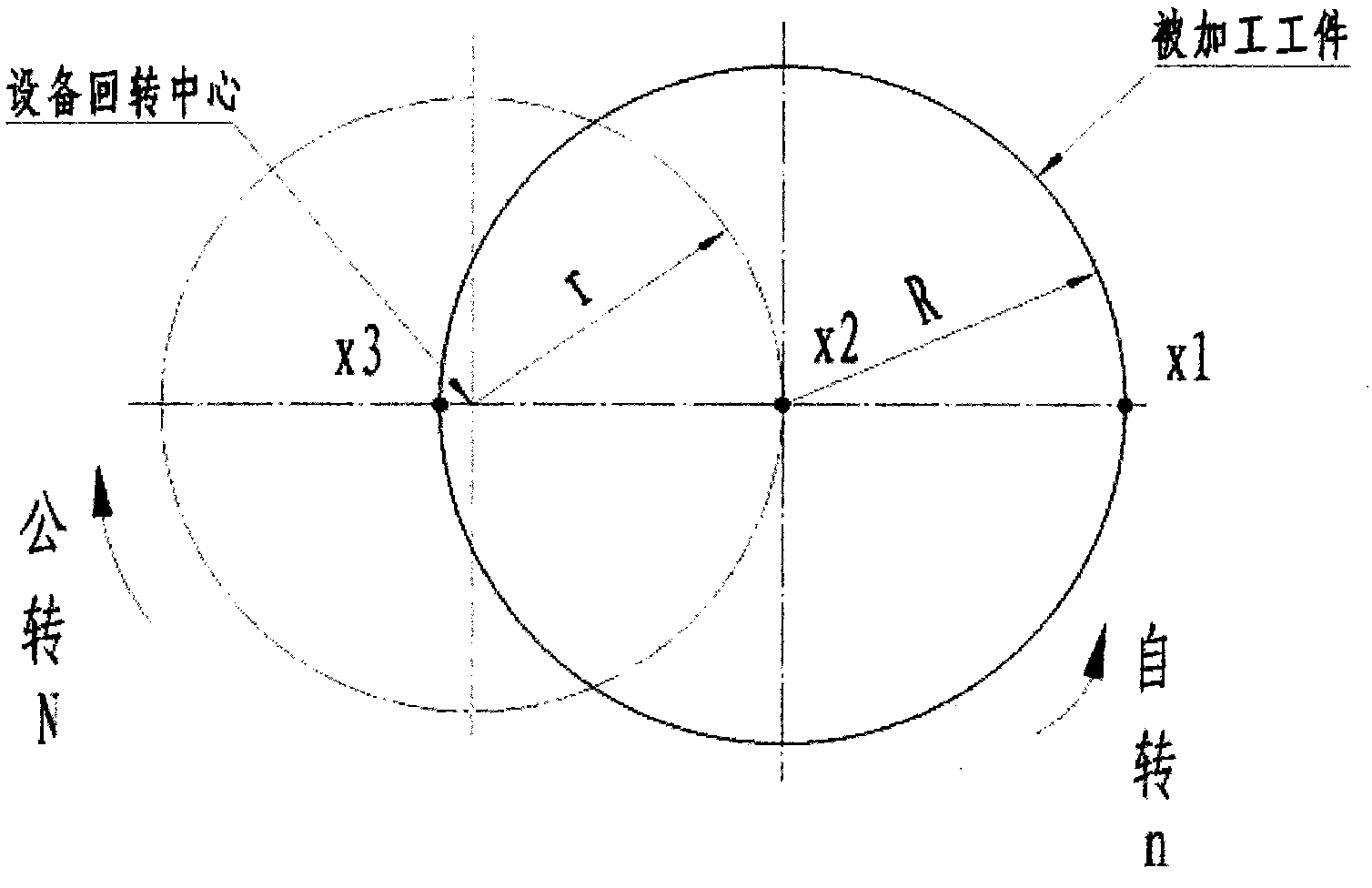

[0046] The workpiece to be processed rotates around the axis of rotation relative to the rotary table, and its axis of rotation is parallel to but not coincident with the axis of rotation of the rotary table; the workpiece to be processed revolves around the axis of rotation of the rotary table while self-propagating; under such motion conditions Next, use flat abrasives or / and powdery or paste abrasives to perform compound finishing operations on the workpiece to be processed.

[0047] The combined automatic finishing method with double driving shafts of the blisk described in this embodiment also includes the following content requirements:

[0048] In the...

Embodiment 2

[0073] 1) In the compound automatic finishing method with double driving shafts of the integral blisk, the specific requirements are:

[0074] The frequency of the main shaft of the equipment is 60-80 Hz, and the vibration frequency of the material box is 55-60 Hz; the revolution of the main shaft / autobiography of the workpiece = 1 / 1.2, and the distance between the two rotating shafts varies between 180-360 mm;

[0075] 2) Finishing medium: silicon corundum; specification of finishing medium: 2-10mm spherical abrasive, particle size: 80-120#; 150#; 300#;

[0076] 3) In the integral blisk double drive shaft compound automatic finishing method, the maximum turning diameter of the workpiece is 600-1000mm, the length range of the workpiece is ≤350mm, the thickness range of the workpiece is ≤600mm, and the total volume of the material box 4 is 500-1000L.

[0077] Example 3

Embodiment 3

[0079] 1) In the compound automatic finishing method with double driving shafts of the integral blisk, the specific requirements are:

[0080] The main shaft frequency of the equipment is 65~80Hz, the vibration frequency of the material box is 50~60Hz;

[0081] 2) Finishing medium: ceramics; specification of finishing medium: 2-10mm spherical abrasive, particle size: 80-120#; 150#; 300#.

[0082] 3) In the combined automatic finishing method with dual drive shafts for the blisk, the maximum turning diameter of the workpiece is 1000-1200mm, the length range of the workpiece is ≤400mm, the thickness range of the workpiece is ≤600mm, and the total volume of the material box 4 is 500-1200L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com