Broken link self-anti-drop loop chain hoisting machine

A hoist and chain technology, applied in portable hoisting devices, hoisting devices, etc., can solve the problems of hoisting heavy objects falling from high altitude, hoisting objects falling rapidly, equipment damage, etc., achieving good sealing performance, compact structure and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

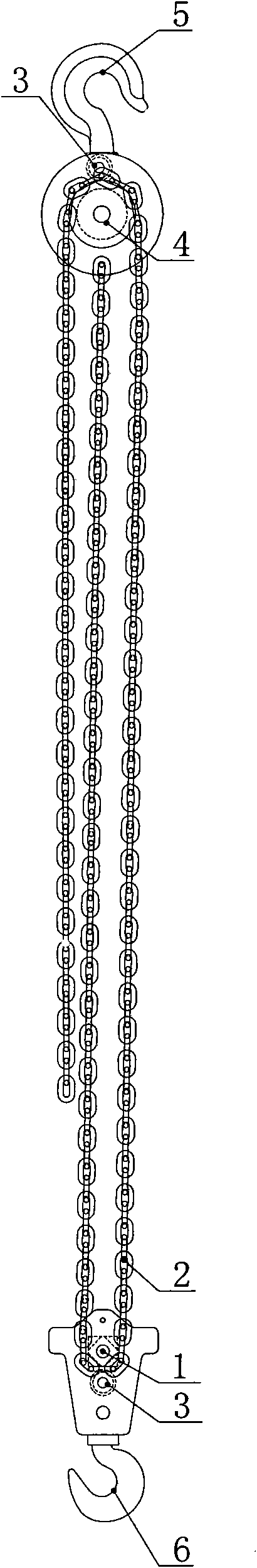

[0032] Embodiment 1: as figure 1 Shown is a schematic structural view of an embodiment of a broken chain self-preventing ring chain hoist using a single sprocket according to the present invention.

[0033]This embodiment includes a driving wheel 4 for providing driving force, an upper hook 5 hooked at the lifting height position, a lower hook 6 for hooking lifting objects, an upper mounting seat 51 fixedly connected with the upper hook 5, and the lower hook 5. The lower mounting base 61 that is fixedly connected with the hook, the drive wheel 4 is installed on the upper mounting base 51, the sprocket 1 is installed on the lower mounting base 61, and the chain 2 meshing with the sprocket 1 and the driving wheel 4 is engaged with the transmission chain 2 at the same time, and the sprocket 1 is installed correspondingly. There is a chain tensioning wheel 3, and the driving wheel 4 is also equipped with a chain tensioning wheel 3, the outer side of the chain 2 meshes with the cha...

Embodiment 2

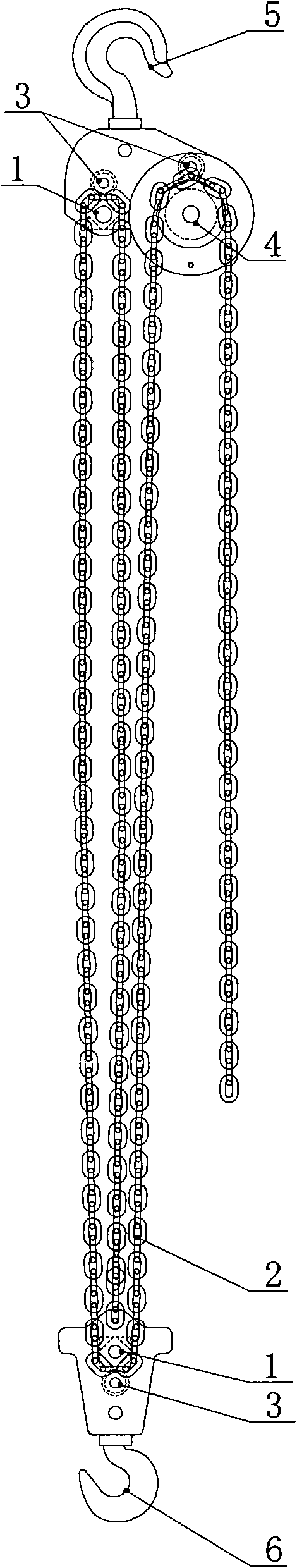

[0042] Embodiment 2: as figure 1 Shown is a schematic structural view of an embodiment of a broken chain self-preventing ring chain hoist using a single sprocket according to the present invention.

[0043] This embodiment includes a driving wheel 4 for providing driving force, an upper hook 5 hooked at the lifting height position, a lower hook 6 for hooking lifting objects, an upper mounting seat 51 fixedly connected with the upper hook 5, and the lower hook 5. The lower mounting base 61 that is fixedly connected with the hook, the drive wheel 4 is installed on the upper mounting base 51, the sprocket 1 is installed on the lower mounting base 61, and the chain 2 meshing with the sprocket 1 and the driving wheel 4 is engaged with the transmission chain 2 at the same time, and the sprocket 1 is installed correspondingly. There is a chain tensioning wheel 3, and the driving wheel 4 is also equipped with a chain tensioning wheel 3, the outer side of the chain 2 meshes with the ch...

Embodiment 3

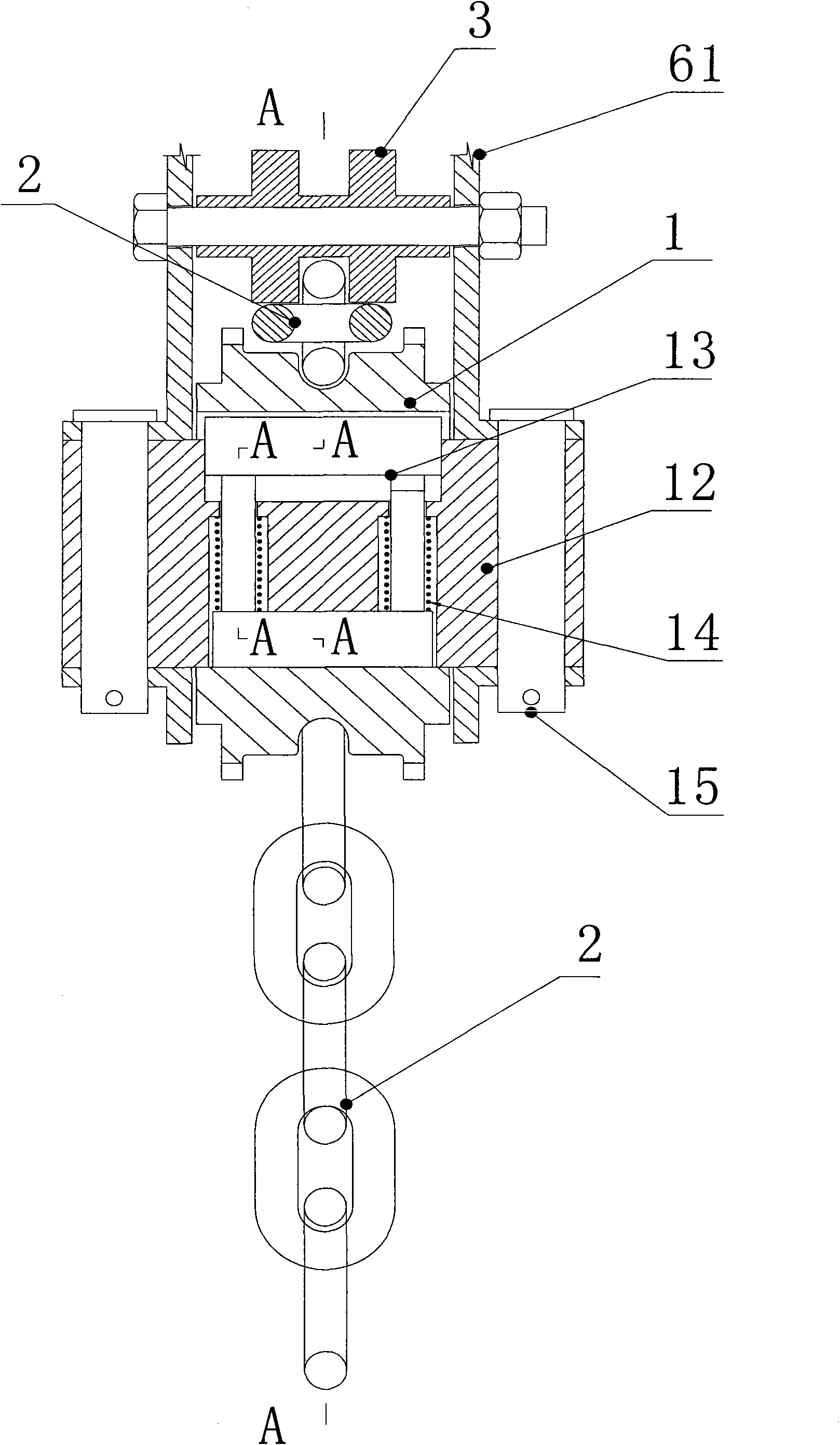

[0051] Embodiment 3: as figure 1 As shown, the embodiment of the broken chain self-preventing ring chain hoist of the present invention uses a single sprocket. It includes a driving wheel 4 for providing driving force, an upper hook 5 hooked at the lifting height position, a lower hook 6 for hooking lifting objects, an upper mounting seat 51 fixedly connected with the upper hook 5, and fixed with the lower hook The connected lower mounting base 61, the drive wheel 4 is installed on the upper mounting base 51, the sprocket 1 is installed on the lower mounting base 61, and the chain 2 is meshed with the sprocket 1 and the driving wheel 4 at the same time, and the sprocket 1 is equipped with a corresponding The chain tensioning wheel 3 and the driving wheel 4 are also equipped with the chain tensioning wheel 3, the outer side of the chain 2 meshes with the chain tensioning wheel 3, the inner side of the chain 2 meshes with the outer contour of the sprocket 1, and one end of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com