Followed vibration well cementation method

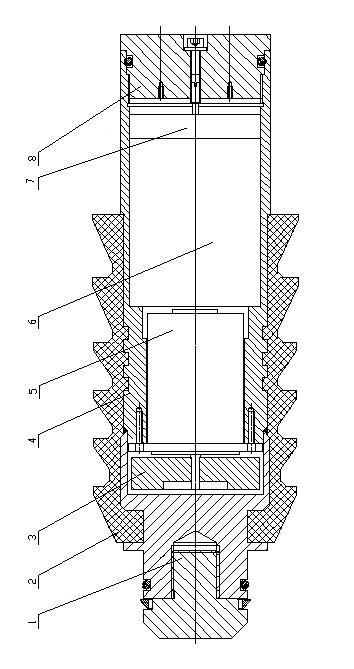

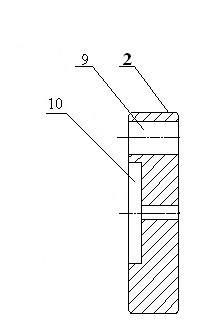

A cementing and resonator technology, applied in the direction of vibration generating device, earthwork drilling, borehole/well components, etc., can solve the problem of no direct correlation of cementing quality, single function of cementing plug, construction technology, structure, etc. Issues such as differences in type and mode of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

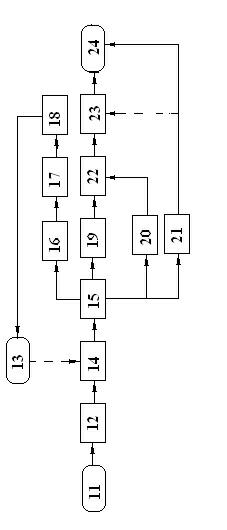

Method used

Image

Examples

Embodiment 1

[0037] Example 1: Implementation method of cementing in test well ##4 in an oil field—according to the drilling data of the open hole well completed with casing and the cementing task book, the initial setting time of the selected cement slurry system is 100 minutes, and the displacement displacement of the equipment is 8L / s. Set the starting time to 20min (the fundamental frequency is automatically set to about 29Hz according to the correlation between the length of the casing and the starting time), and the vibration duration to 30min. The application effect obtained by acoustic amplitude logging is that the high-quality rate of the sealing section reaches 86.5%, the qualified rate is 100%, and the cementing quality is evaluated as excellent.

Embodiment 2

[0038] Example 2: Implementation method of cementing in an exploration well ##105 in an oil field—according to the drilling data of the open hole well completed with casing and the cementing task statement, the initial setting time of the selected cement slurry system is 110 minutes, and the displacement displacement of the equipment is 8L / s. Set the starting time to 25min (the fundamental frequency is automatically set to about 27Hz according to the correlation between the length of the casing and the starting time), and the vibration duration to 40min. The application effect obtained by acoustic amplitude logging is that the high-quality rate of the sealing section reaches 97.6%, the qualified rate is 100%, and the cementing quality is evaluated as excellent.

Embodiment 3

[0039] Example 3: Implementation method of cementing in development well ##66 in an oilfield—according to the drilling data of open hole wells completed with casing and the cementing task book, the initial setting time of the selected cement slurry system is 120min, and the displacement displacement of the equipment is 8L / s, set the starting time to 30min (the base frequency is automatically set to about 26Hz according to the correlation between the length of the casing and the starting time), and the vibration duration to 50min. The application effect obtained by acoustic amplitude logging is that the high-quality rate of the sealing section reaches 65.1%, the qualified rate is 100%, and the cementing quality evaluation is good.

[0040] Therefore, the advantages of the present invention are as follows:

[0041] (1) Avoid the single function of conventional rubber plugs, and increase the function of movable sleeves;

[0042] (2) Without changing the existing construction te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com