Extrusion type rubber bushing structure

A rubber bushing and bushing technology, applied to springs, springs/shock absorbers, mechanical equipment, etc. made of plastic materials, can solve the problems of non-replaceable and difficult rubber bushings, and achieve simple structure and cost saving , the effect of easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

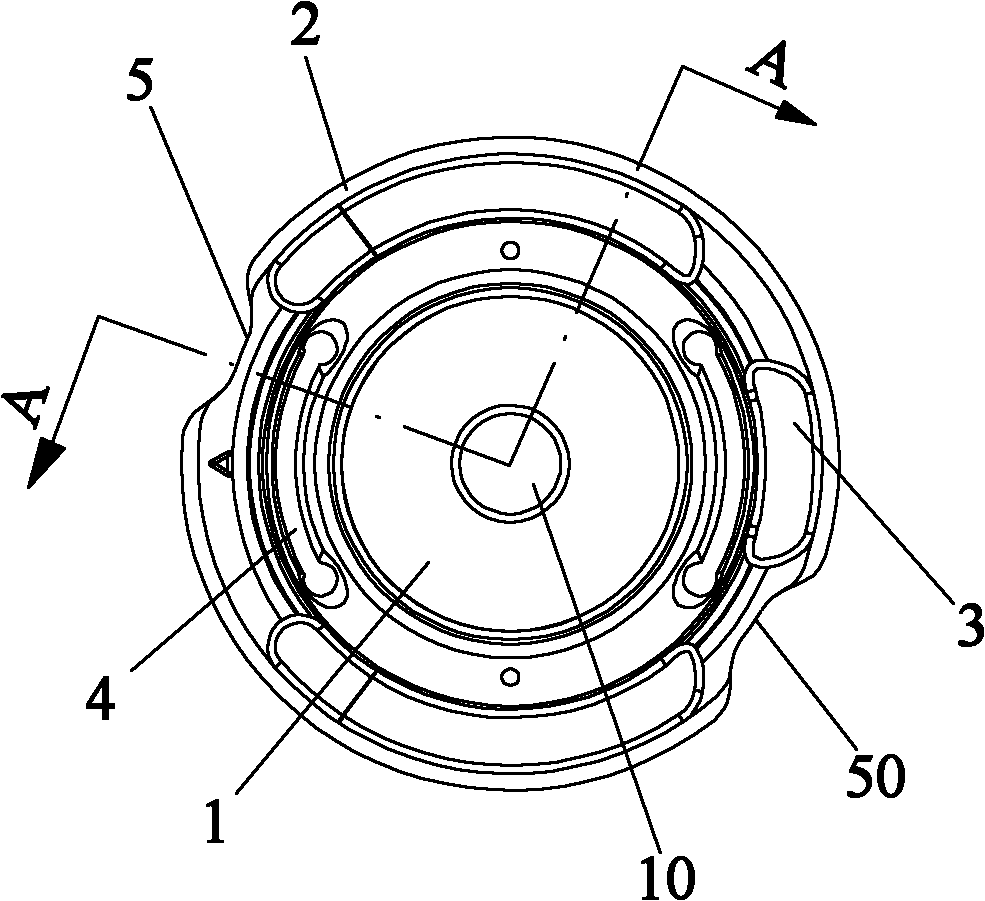

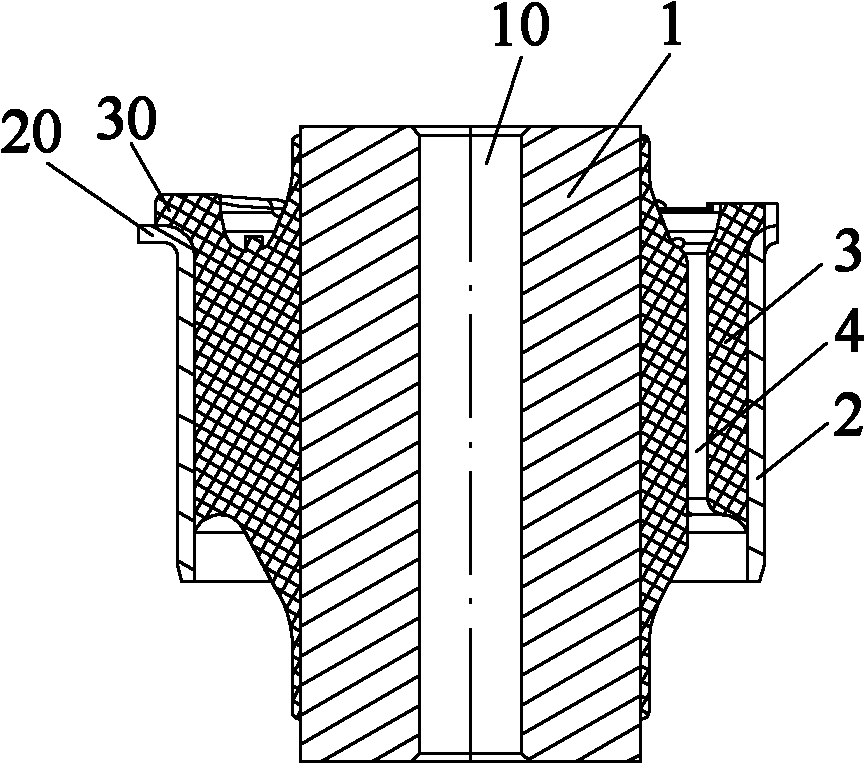

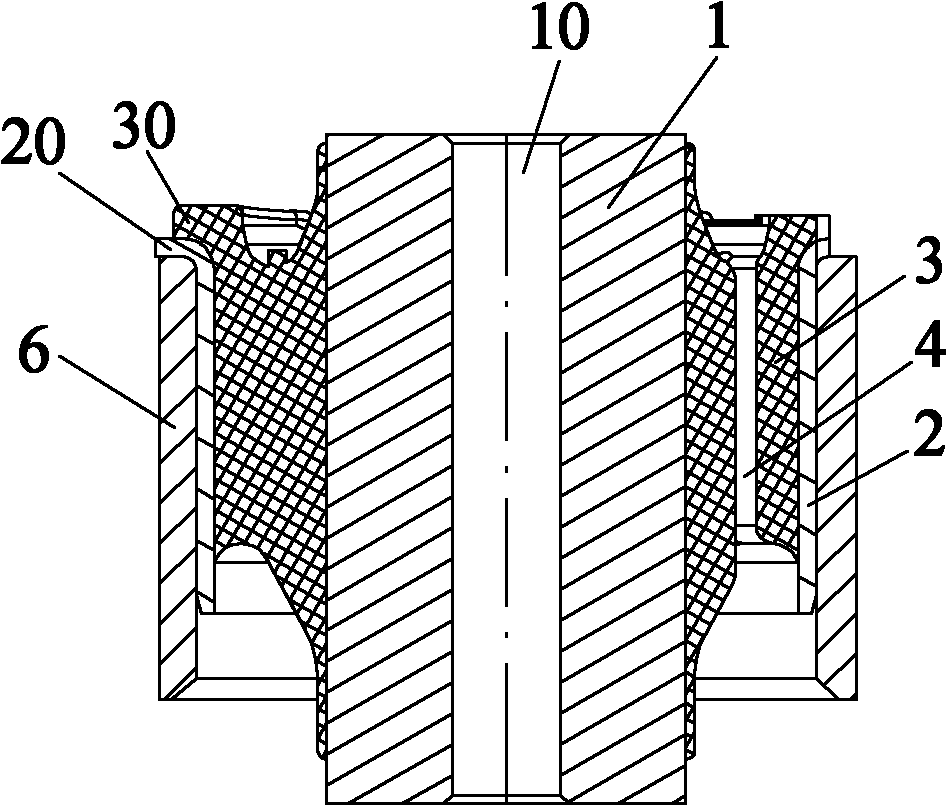

[0017] Example 1, such as Figure 1 to Figure 3 As shown, an extrudable rubber bushing structure, the rubber bushing is pressed into the bushing sleeve 6 fixed on the vehicle body bracket or torsion beam, which includes a bushing inner tube 1 and a bushing outer tube 2 And the rubber layer 3 vulcanized between the bush inner tube and the bush outer tube, the materials of the bush inner tube 1 and the bush outer tube 2 are all cast iron; the bush inner tube 1 is provided with a bush inner hole 10. Fixing bolts are passed through the inner hole 10 of the bushing to fix it on the vehicle body; the outer tube 1 of the bushing is provided with an outer tube flanging 20, and the rubber layer is vulcanized until the outer tube flanging forms a rubber layer Flanging 30, the diameter of outer tube flanging 20 is larger than the diameter of the bushing sleeve 6 used for press-fitting the rubber bushing; the outer tube flanging 20 and the rubber layer flanging 30 are provided with a grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com