Manual slag raking machine

The technology of a slag scraper and a support device is applied in the field of cleaning tools, which can solve problems such as enterprise losses, and achieve the effects of improving the use efficiency, the tool structure is simple, and the economic benefit is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

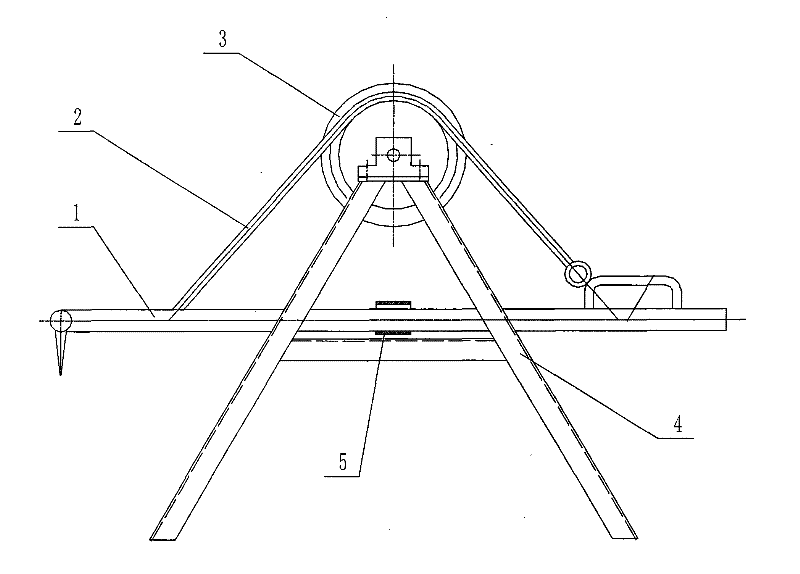

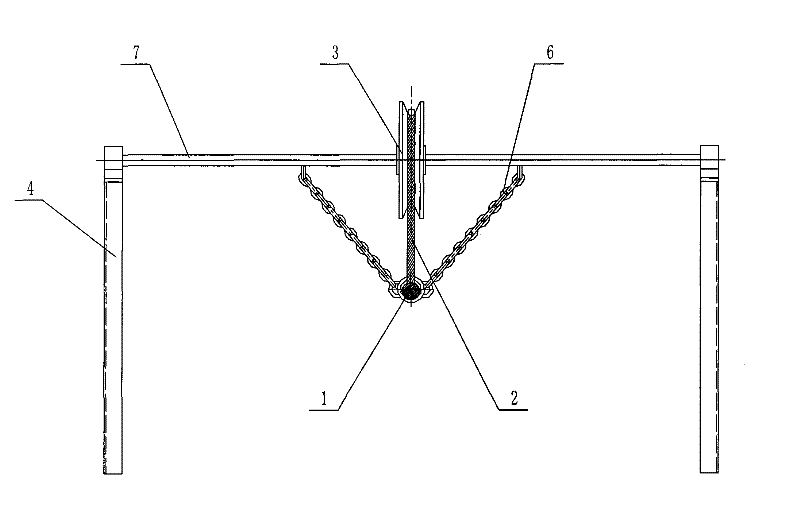

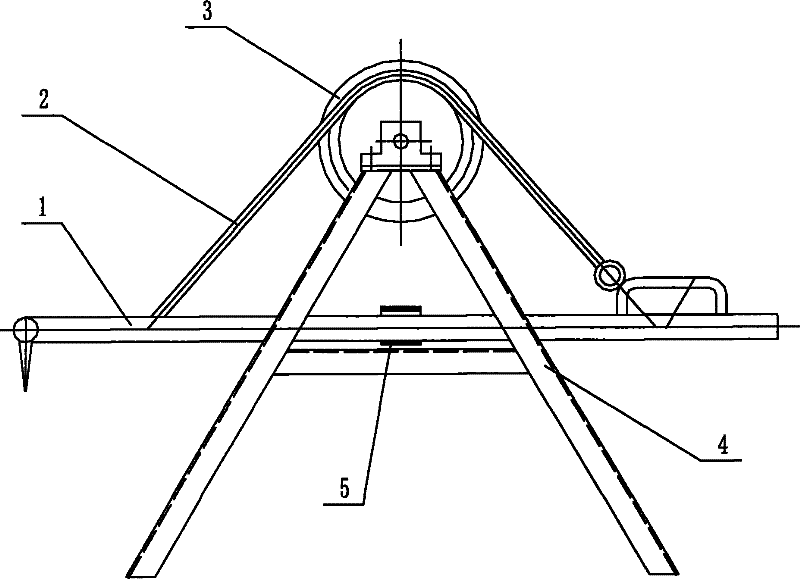

[0011] Manual slag removal machine, such as figure 1 , figure 2 As shown, it includes a supporting device, a positioning device and an iron rake 1, the supporting device includes a pole 7 and a support 4, and the two ends of the pole 7 are vertically fixed with the support 4. The positioning device comprises a pulley 3, a steel rope 2 and a slide chain 6, the pulley 3 is installed in the middle part of the pole 7, the pole 7 on both sides of the pulley 3 is equipped with a slide chain 6, and the bottom ends of the two slide chains 6 are fixed on a sleeve 5, and the sleeve An iron rake 1 is installed in the cylinder 5, and the iron rake 1 on both sides of the sleeve 5 is connected with a steel rope 2, and the iron rake 1 is connected with the pulley 3 through the steel rope 2.

[0012] When removing slag, adjust the steel rope 2 and the zipper 6 so that the iron rake 1 is at the desired height. The operator holds the tail of the iron rake 1 and extends the head of the iron ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com