Adjusting mechanism

A technology for adjusting the mechanism and adjusting the structure, applied in the field of photolithography, can solve the problem that the slide table is difficult to meet the requirements, etc., and achieve the effects of low manufacturing cost, simple operation, and easy processing and manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the above and other objects, features and advantages of the present invention more comprehensible, preferred embodiments are described below in detail with accompanying drawings.

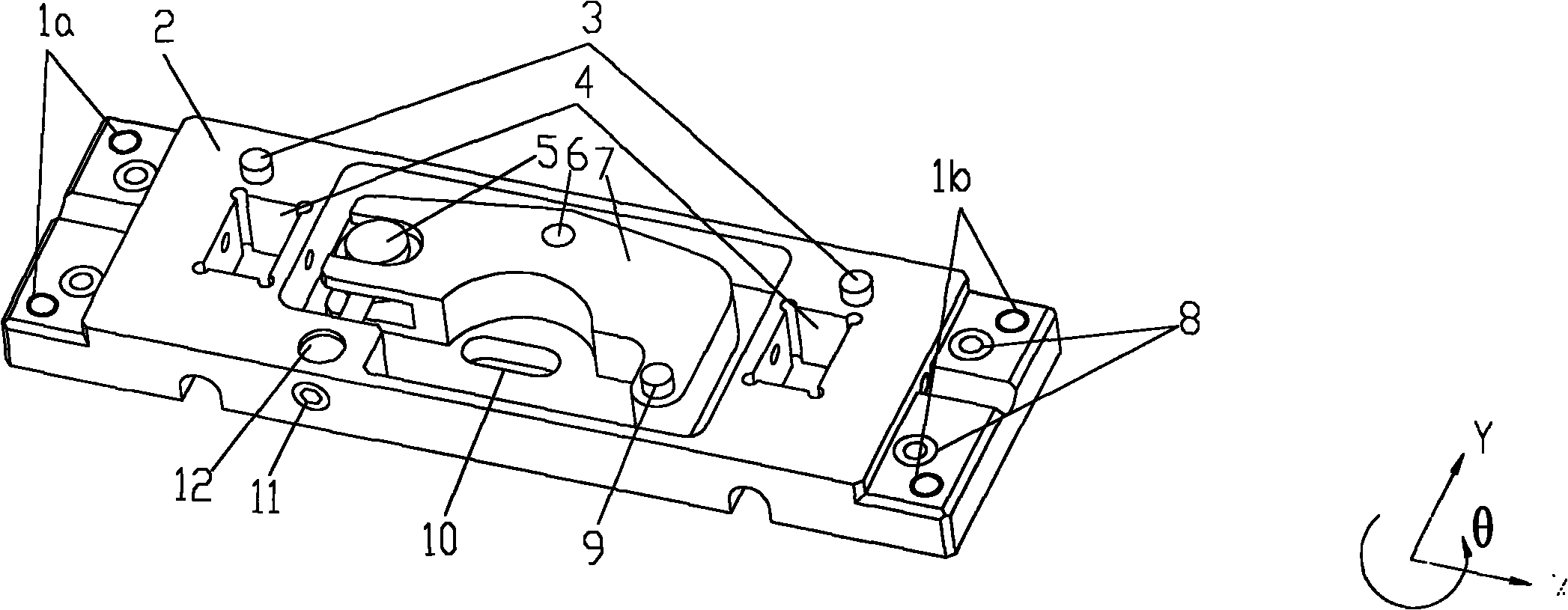

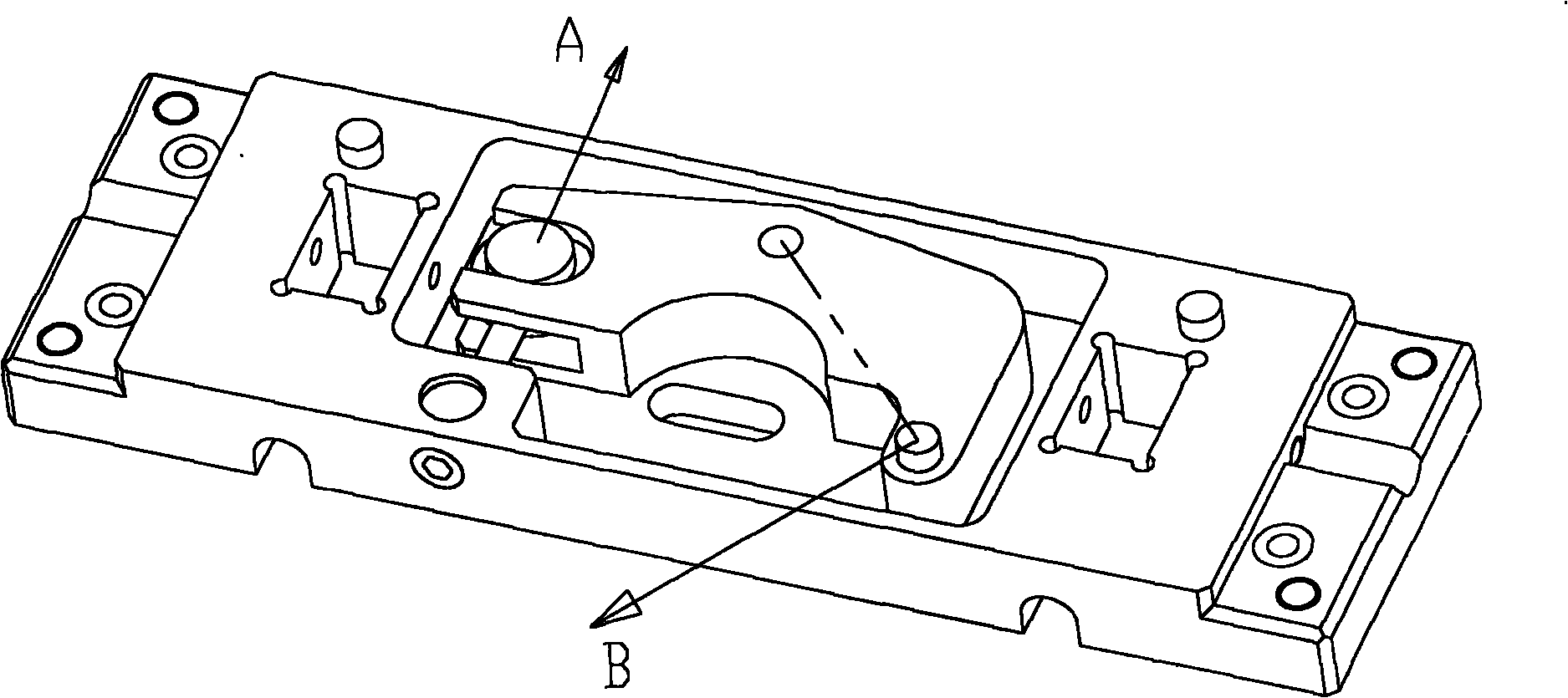

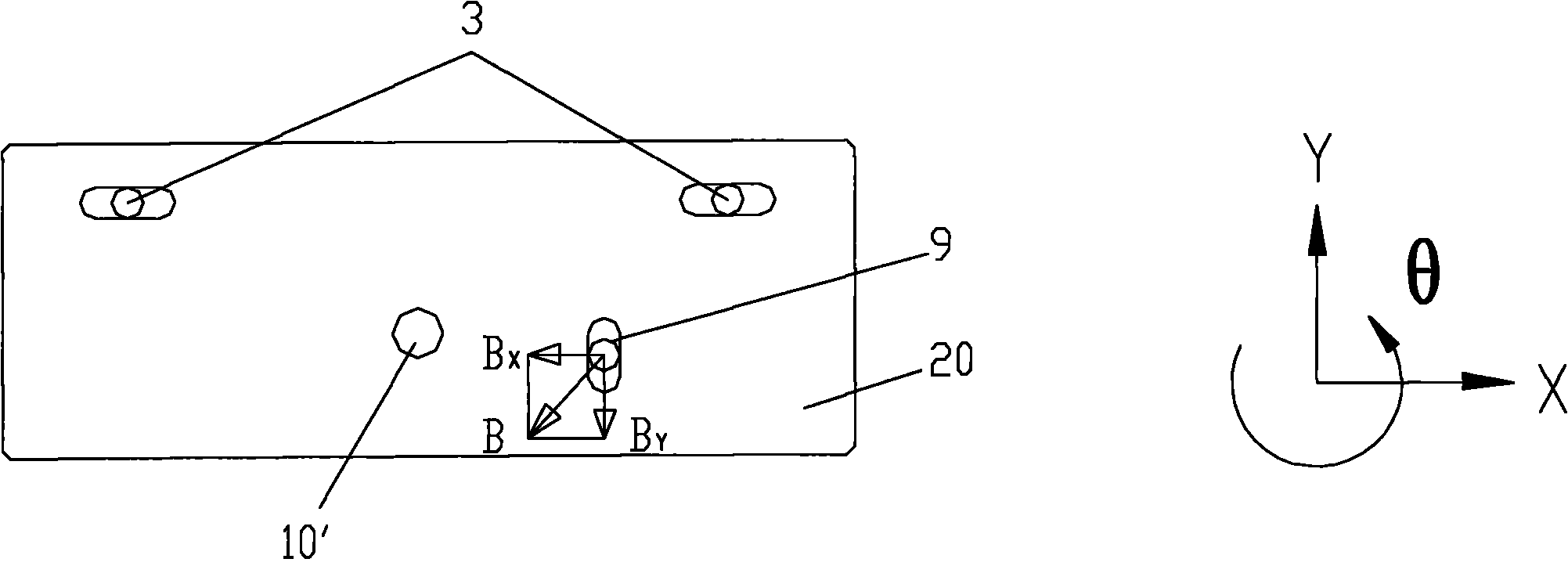

[0016] The adjustment mechanism is mainly composed of X-direction structure, Y-direction structure, θ-direction structure, etc., and is based on the rotation of the adjustment element to drive the movement of each axis. The structures in three directions are organically combined without interfering with each other. The entire adjustment mechanism is respectively arranged from bottom to top: base, X-direction structure, θ-direction structure and Y-direction structure. Among them, the X direction and the Y direction are perpendicular to each other, the X direction, the Y direction, and the Z direction are perpendicular to each other, and the θ direction rotates around the Z axis, that is, the Rz direction. Of course, the idea based on this patent can also be transformed into o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com