Process and apparatus for separating solids from gas

A technology of separation and gas outlet, applied in the direction of separation method, dispersed particle separation, chemical instrument and method, etc., can solve the problems of internal corrosion of metal cyclone, damage to cyclone, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

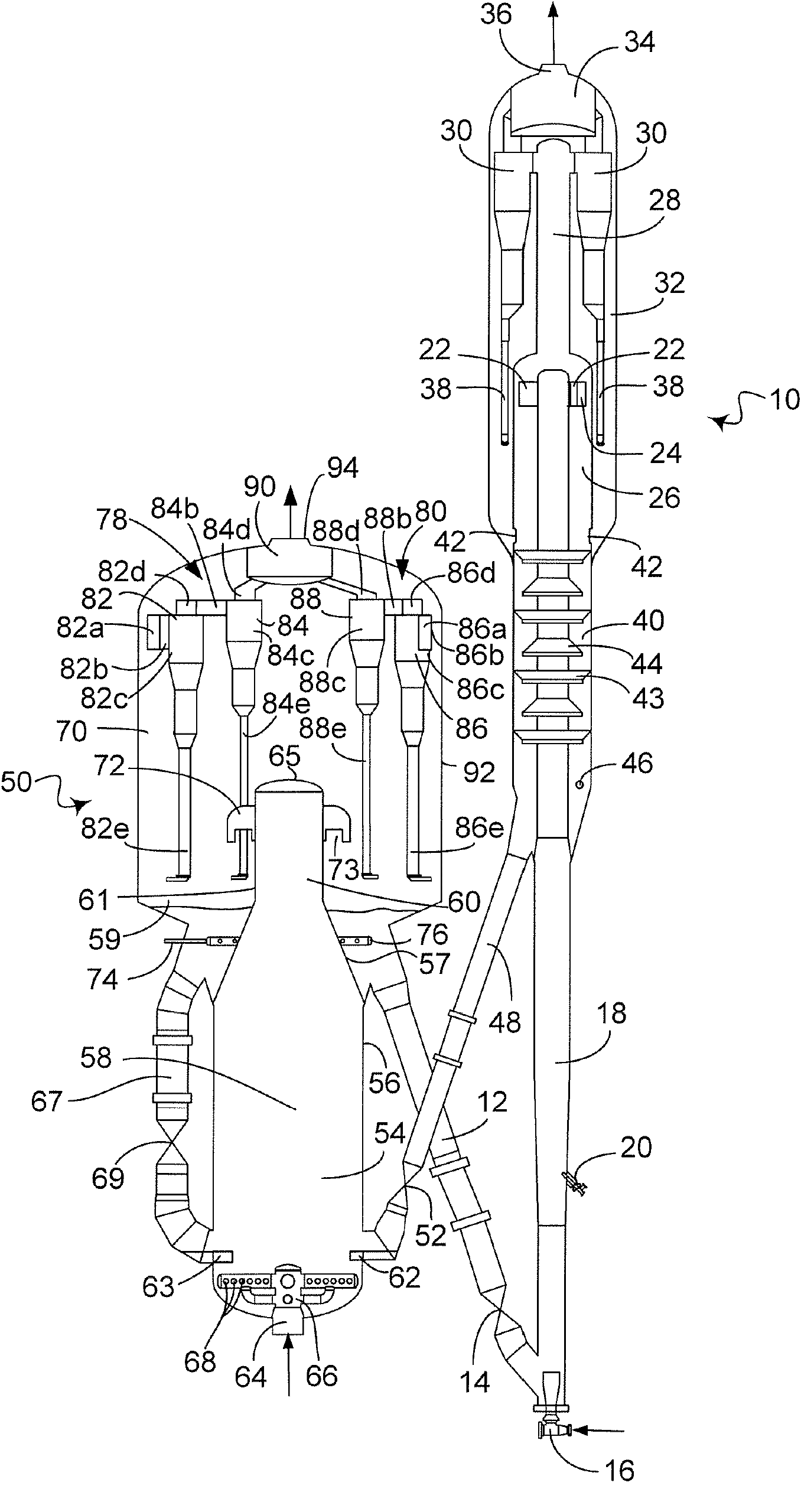

[0012] Although the apparatus and method of the present invention can be used in any solid-gas separation plant, it is immediately applicable in an FCC unit. figure 1 An FCC unit comprising a reactor vessel 10 and a regenerator vessel 50 is shown. Regenerator standpipe 12 conveys catalyst from regenerator vessel 50 to reactor riser 18 at a rate regulated by slide valve 14 . A fluidizing medium—such as steam from nozzle 16—conveys the catalyst at a higher density upward through riser 18 until a plurality of feed injection nozzles 20 (only one shown) are injected transversely to the flow stream of catalyst particles. material.

[0013] Suitable feeds are conventional FCC feeds or higher boiling hydrocarbon feeds. One of the most common of such conventional feedstocks is "vacuum gas oil" (VGO), which is vacuum fractionated atmospheric slag typically boiling between 343 and 552°C (650 and 1025°F). Hydrocarbon materials for the preparation of oil. In this fraction, there are ge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com