Method for modeling control circuit for processing machine

A technology for regulating loops and processors, applied to printing machines, general parts of printing machinery, printing, etc., can solve problems such as insufficient to achieve optimal results, interference characteristics, and no adjustments, so as to save manual input and avoid The effect of important error sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

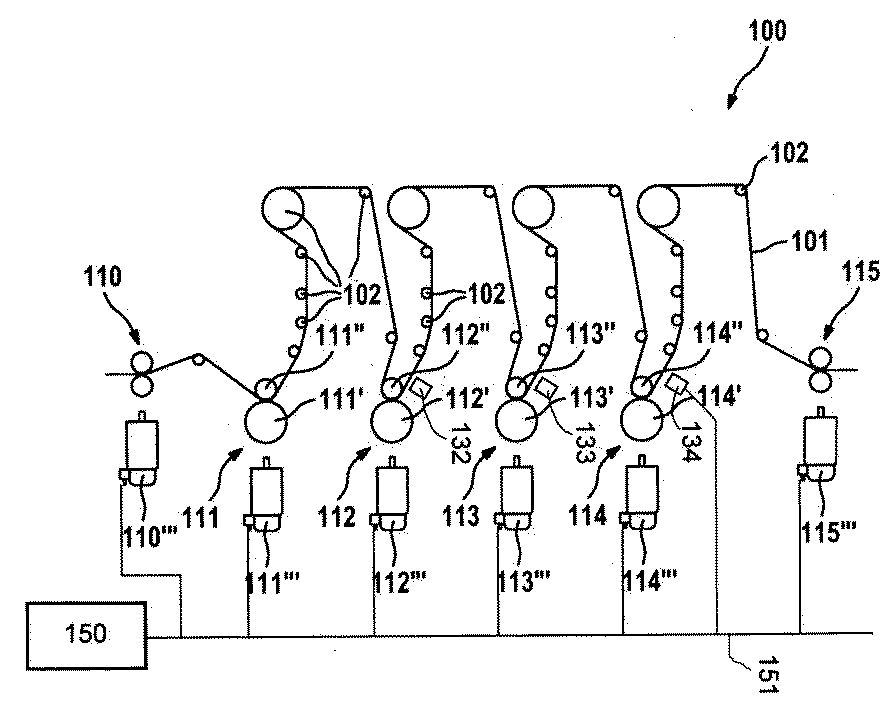

[0031] exist figure 1 A processing machine configured as a printing press is generally indicated with 100 . Printed material, such as paper 101 , is fed to the machine by an infeed 110 . The paper 101 is guided and printed by processing devices designed as printing units 111 , 112 , 113 , 114 and is output again by an outfeed 115 . The in-feed, out-feed and printing means are arranged positionally, in particular cylindrically or angularly. The printing units 111 to 114 are located in the region of the rail voltage regulation between the inlet unit 110 and the outlet unit 115 .

[0032] The printing units 111 to 114 each have impression cylinders 111' to 114', which bear against the respective top rollers 111'' to 114'' with great pressure. The impression cylinders can be driven individually and independently. The associated drives 111''' to 114''' are shown schematically. The pressure roller is designed to be freely rotatable. The printing units 111 to 114 each form a fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com