Electrode thermostat container

A technology of welding rod heat preservation and heat preservation box, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as high center of gravity, influence on welding, easy to fall, etc., so as to improve service life and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

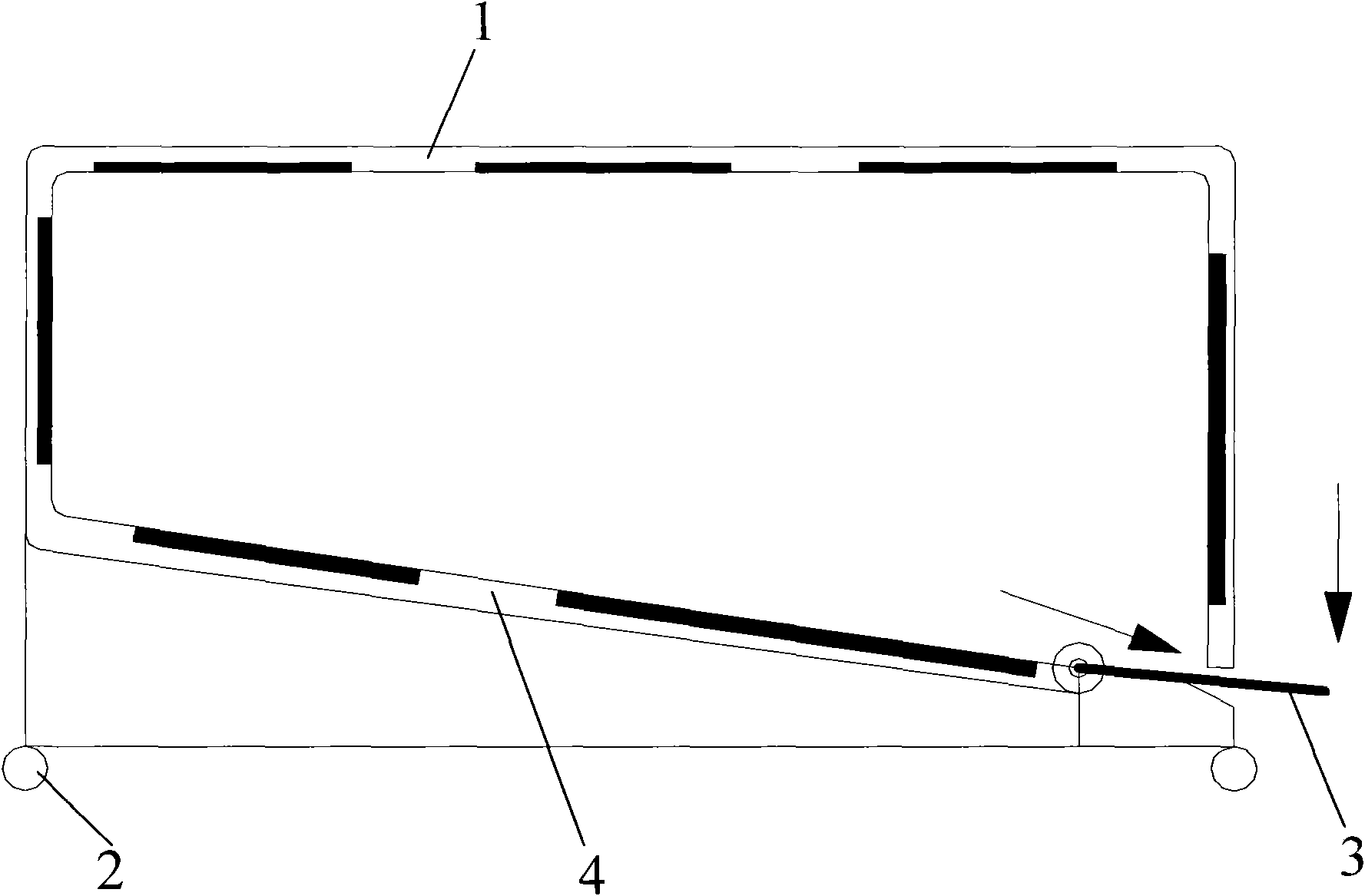

[0014] Such as figure 1 As shown, the welding rod incubator, the box 1 of the incubator is a horizontal structure, the box 1 includes two layers inside and outside, a glass fiber heat insulation layer is provided between the inner layer and the outer layer, and an electric heater is attached to the inner wall of the inner layer. The inner cavity of the box body is provided with an inclined support plate 4, and the box wall at the bottom end of the inclined support plate has a discharge port, and a spring leaf 3 is installed on the box body wall next to the discharge port, and the spring leaf 3 and The outlets are in contact with each other; the bottom of the incubator is equipped with universal wheels 2; the body of the incubator is provided with a collection box.

[0015] The inner wall of the inner layer of the box is pasted with an electric heating sheet, and the power supply of the electric heating sheet adopts the current and voltage of the input terminal of the welding m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com