All-steel loading radial tire with zero-degree belted layer structure

A radial tire and belt technology, applied in the field of all-steel radial truck tires, can solve problems such as economic losses, and achieve the effects of extending service life, high shear resistance, and delaying damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

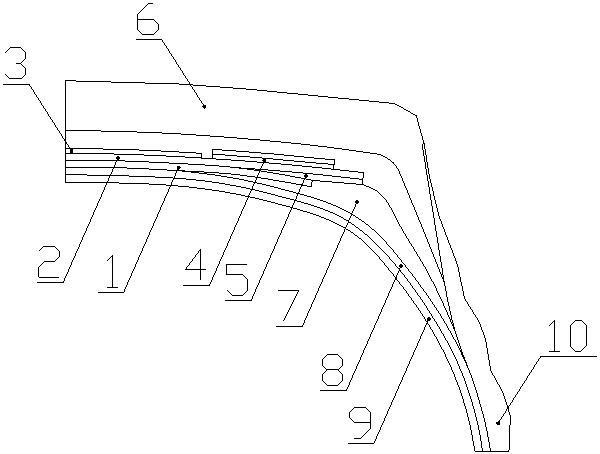

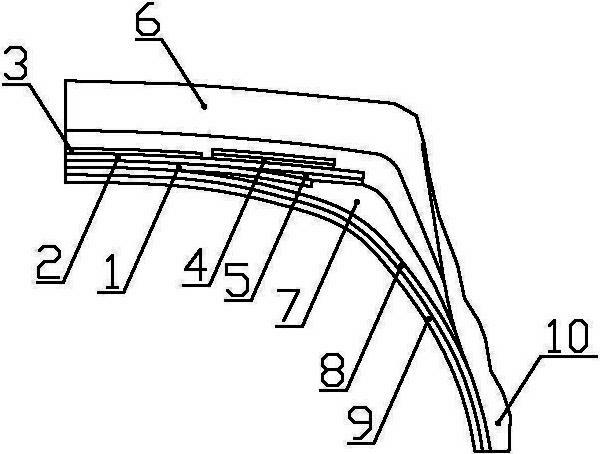

[0011] Such as figure 1 The all-steel load-bearing radial tire with zero-degree belt structure shown, the all-steel load-bearing radial tire includes a crown 6, a belt layer, a shoulder pad rubber 7, a carcass ply 8, an inner liner 9 and a sidewall 10, The belt layer is composed of the first belt layer 1, the second belt layer 2, the third belt layer 3 and the zero degree belt layer 4, between the ends of the first belt layer 1 and the second belt layer 2 Nylon fiber cord 5 is arranged between them, nylon fiber cord 5 is inserted between the ends of the first belt layer 1 and the second belt layer 2, and extends to between the second belt layer 2 and the shoulder pad rubber , the ends of the nylon fiber cord 5 are flush with the ends of the second belt layer 2 .

[0012] The applicant added nylon fiber cord 5 between the end po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com