Preparation method and application of multi-component copolymerized filtrate reducer

A technology of fluid loss reducer and multi-component copolymerization, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of reducing cement slurry viscosity and fluid loss, cumbersome configuration process, etc., to ensure water solubility, high durability Temperature, improve the effect of temperature and salt tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

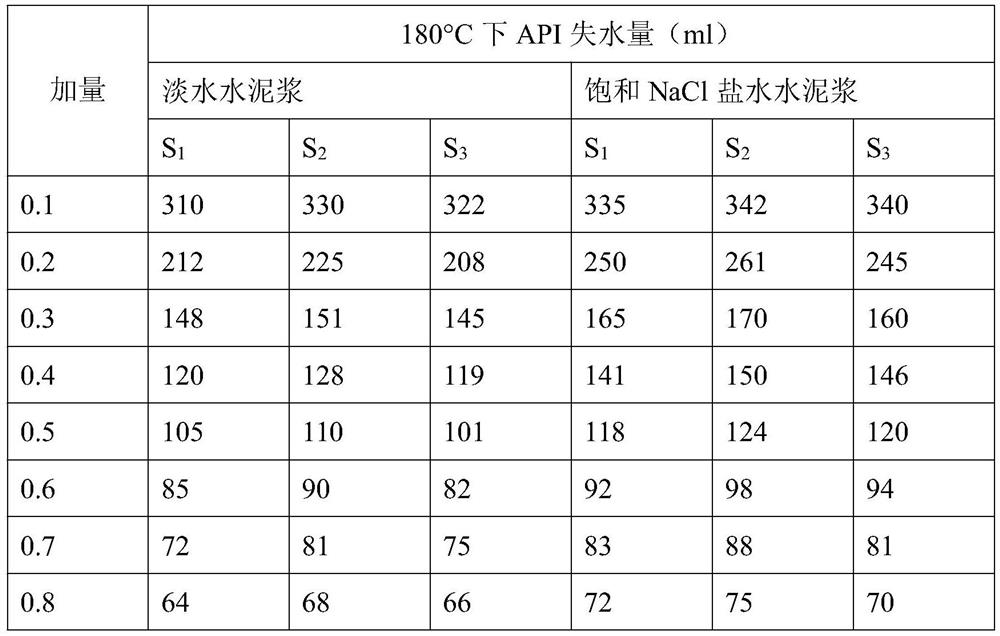

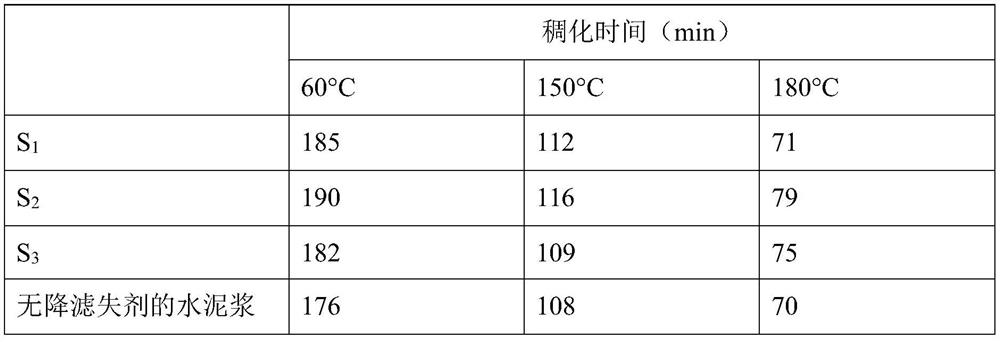

Examples

Embodiment 1

[0030] 1) dissolving 20 parts by mass of β-acryloyloxy potassium propionate in 450 parts of deionized water to obtain a β-acryloyloxy potassium propionate solution;

[0031] 2) after vacuuming and defoaming, the β-acryloyloxy potassium propionate solution is evenly divided into three parts;

[0032] 3) 85 parts of sodium 2-acrylamido-2-methylpropanesulfonate, 133 parts of acrylamide and 100 parts of acryloyl morpholine were respectively added to three parts of β-acryloyloxypropionate potassium solution to obtain 2 - sodium acrylamido-2-methylpropanesulfonate solution, acrylamide solution and acryloylmorpholine solution;

[0033] 4) mixing acrylamide solution and acryloyl morpholine solution, wherein the mass ratio of acrylamide and acryloyl morpholine is 1.33:1;

[0034] 5) Add N,N'-methylenebisacrylamide, sodium hypophosphite, sodium metabisulfite, sodium persulfate to the mixed solution of step 4, wherein, N,N'-methylenebisacrylamide, sodium hypophosphite , sodium metabisu...

Embodiment 2

[0038] 1) dissolving 25 parts by mass of β-acryloyloxy potassium propionate in 450 parts of deionized water to obtain a β-acryloyloxy potassium propionate solution;

[0039] 2) after vacuuming and defoaming, the β-acryloyloxy potassium propionate solution is evenly divided into three parts;

[0040]3) 87 parts of sodium 2-acrylamido-2-methylpropanesulfonate, 135 parts of acrylamide and 100 parts of acryloyl morpholine were respectively added to three parts of β-acryloyloxypropionate potassium solution to obtain 2 - sodium acrylamido-2-methylpropanesulfonate solution, acrylamide solution and acryloylmorpholine solution;

[0041] 4) mixing acrylamide solution and acryloyl morpholine solution, wherein the mass ratio of acrylamide and acryloyl morpholine is 1.35:1;

[0042] 5) Add N,N'-methylenebisacrylamide, sodium hypophosphite, sodium metabisulfite, sodium persulfate to the mixed solution of step 4, wherein, N,N'-methylenebisacrylamide, sodium hypophosphite , sodium metabisul...

Embodiment 3

[0046] 1) dissolving 22 parts by mass of β-acryloyloxy potassium propionate in 450 parts of deionized water to obtain a β-acryloyloxy potassium propionate solution;

[0047] 2) after vacuuming and defoaming, the β-acryloyloxy potassium propionate solution is evenly divided into three parts;

[0048] 3) 86 parts of sodium 2-acrylamido-2-methylpropanesulfonate, 134 parts of acrylamide and 100 parts of acryloyl morpholine were respectively added to three parts of β-acryloyloxypropionate potassium solution to obtain 2 - sodium acrylamido-2-methylpropanesulfonate solution, acrylamide solution and acryloylmorpholine solution;

[0049] 4) mixing acrylamide solution and acryloyl morpholine solution, wherein the mass ratio of acrylamide and acryloyl morpholine is 1.34:1;

[0050] 5) Add N,N'-methylenebisacrylamide, sodium hypophosphite, sodium metabisulfite, sodium persulfate to the mixed solution of step 4, wherein, N,N'-methylenebisacrylamide, sodium hypophosphite , sodium metabisu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com