Amino polyether and its preparation method, amino polyether block silicone oil and its preparation method

An amino polyether, block silicone oil technology, applied in textiles, papermaking, fiber processing, etc., can solve the problems of high bulkiness, loss of hydrophilicity, easy to stick to rollers, stick to cylinders, etc., to achieve increased amino content, softness The effect of improved performance, improved softness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention is described in detail below in conjunction with embodiment:

[0046] Mix the first double-ended amino polyether A, the second double-ended amino polyether B and the double-ended epoxy polyether C according to the weight ratio in Table 1, and an addition reaction occurs.

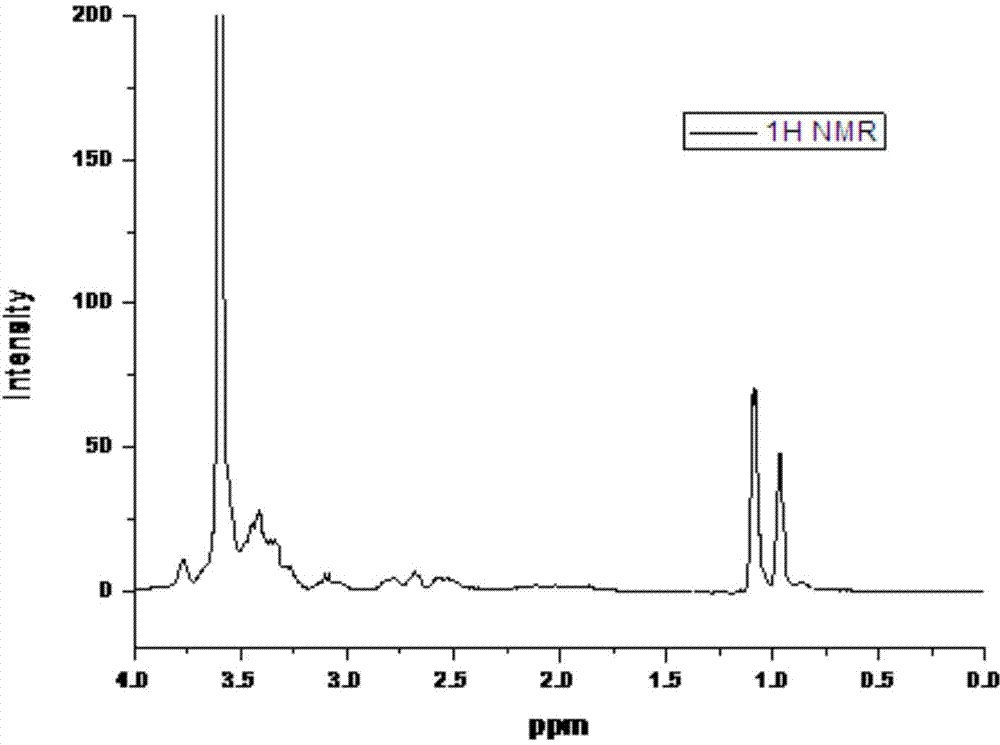

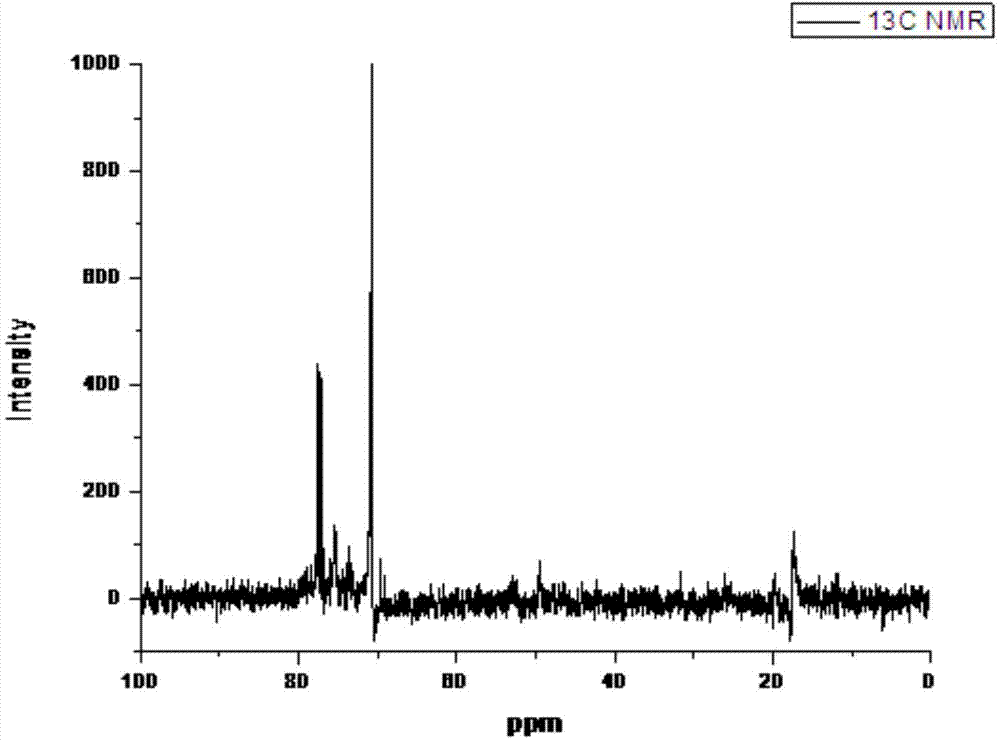

[0047] h 2 NC 3 h 6 (OC 3 h 6 ) a (OC 2 h 4 ) b (OC 3 h 6 ) a NH 2 (A)

[0048] h 2 NC 3 h 6 (OC 3 h 6 ) d NH 2 (B)

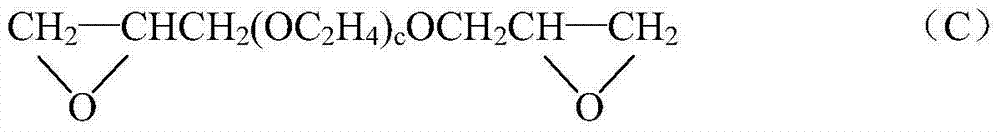

[0049]

[0050] h 2 NC 3 h 6 (OC 3 h 6 ) a (OC 2 h 4 ) b (OC 3 h 6 ) a NHCH 2 CH(OH)CH 2 (OC 2 h 4 ) c OCH 2 CH(OH)CH 2 NHC 3 h 6 (OC 3 h 6 ) d NH 2 (D)

[0051] The values of a, b, c, and d and the temperature and time of the addition reaction are shown in Table 1.

[0052] Table 1

[0053] Wherein the measurement unit of each substance is parts by weight, the unit of temperature is °C, the unit of reaction time is hour, and the reactions in Examples 1 to 10 are carried out under normal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com