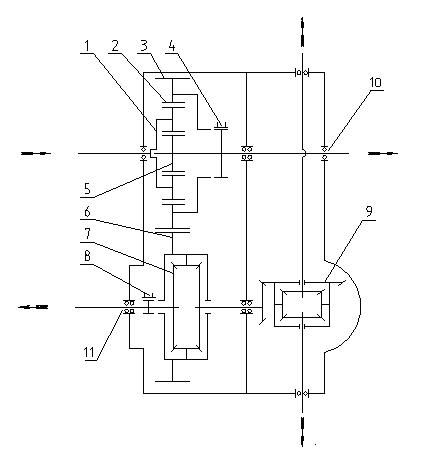

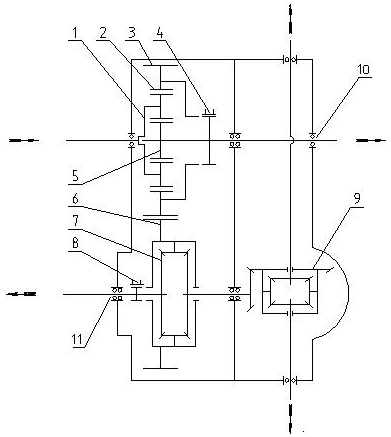

Integral structure of transfer case and middle axle

A transfer case and integrated technology, applied in the direction of control devices, transportation and packaging, vehicle parts, etc., can solve the problem of difficult off-road vehicle layout and meet the off-road needs of vehicles, and achieve light weight, novel structure and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The planetary carrier 1 meshes with the ring gear 2 and the sun gear 5 respectively through planetary gears, wherein the ring gear 2 is connected with the driving cylindrical gear 3 through splines, and the driven cylindrical gear 6 is connected with the spur bevel gear planetary mechanism 7 through splines. The sun gear 5 is connected to the through shaft 10 through a spline, the differential lock 1 is fixedly connected to the through shaft 10, the ring gear 2 is locked to the through shaft through the differential lock 1, and the differential lock 2 8 is connected to the front axle input shaft 11 , The straight bevel gear planetary mechanism 7 is connected with the speed reducer 9 .

[0008] The power is input to the ring gear 2 and the sun gear 5 through the planet carrier 1 of the cylindrical gear planetary mechanism, and the ring gear 2 is input to the straight bevel gear planetary structure 7 through the driving cylindrical gear 3 and the driven cylindrical gear 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com