Maze eddy folded plate flocculation pool

A folded plate flocculation and reaction tank technology, applied in the direction of flocculation/sedimentation water/sewage treatment, etc., can solve the problems of waste of medicines, low flocculation efficiency, and affecting the quality of process effluent, and achieve the effect of increasing the probability of collision and improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

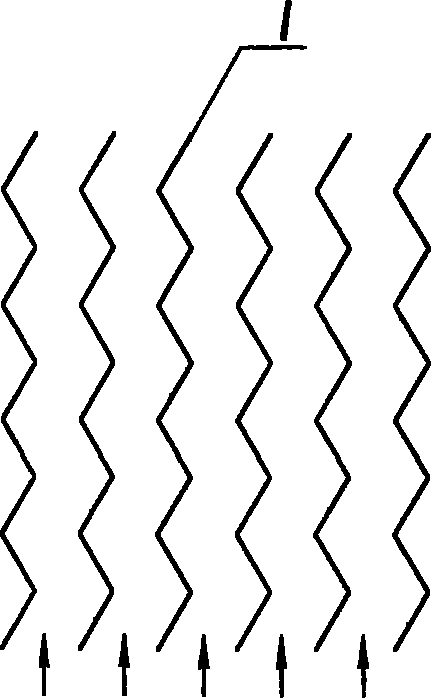

[0010] C-type labyrinth vortex folded plate flocculation reaction tank, several groups of folded plates 1 in the reaction tank are arranged in parallel.

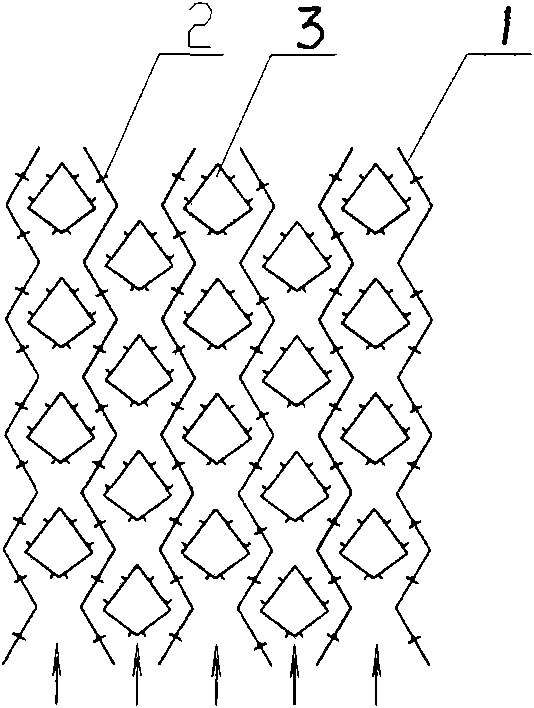

[0011] Type A labyrinth vortex folded plate flocculation reaction tank, several groups of folded plates 1 are symmetrically arranged in the reaction tank, fins 2 are placed on the folded plates 1, and polygonal speed regulators 3 are arranged between the folded plates.

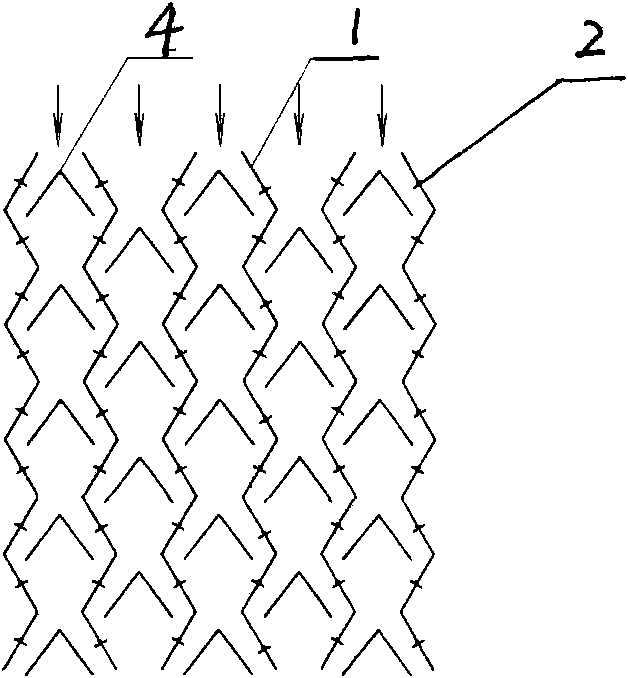

[0012] In the B-type labyrinth vortex flap flocculation reaction tank, several groups of flaps 1 are symmetrically arranged in the reaction tank, with fins 2 placed on the flaps 1, and V-shaped deflectors 4 arranged between the flaps.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com