Polishing equipment and method without subsurface damage

A technology of subsurface damage and equipment, which is applied in the field of non-subsurface damage polishing equipment, can solve problems such as subsurface damage of optical components, and achieve the effects of improving surface quality, increasing ionization rate, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

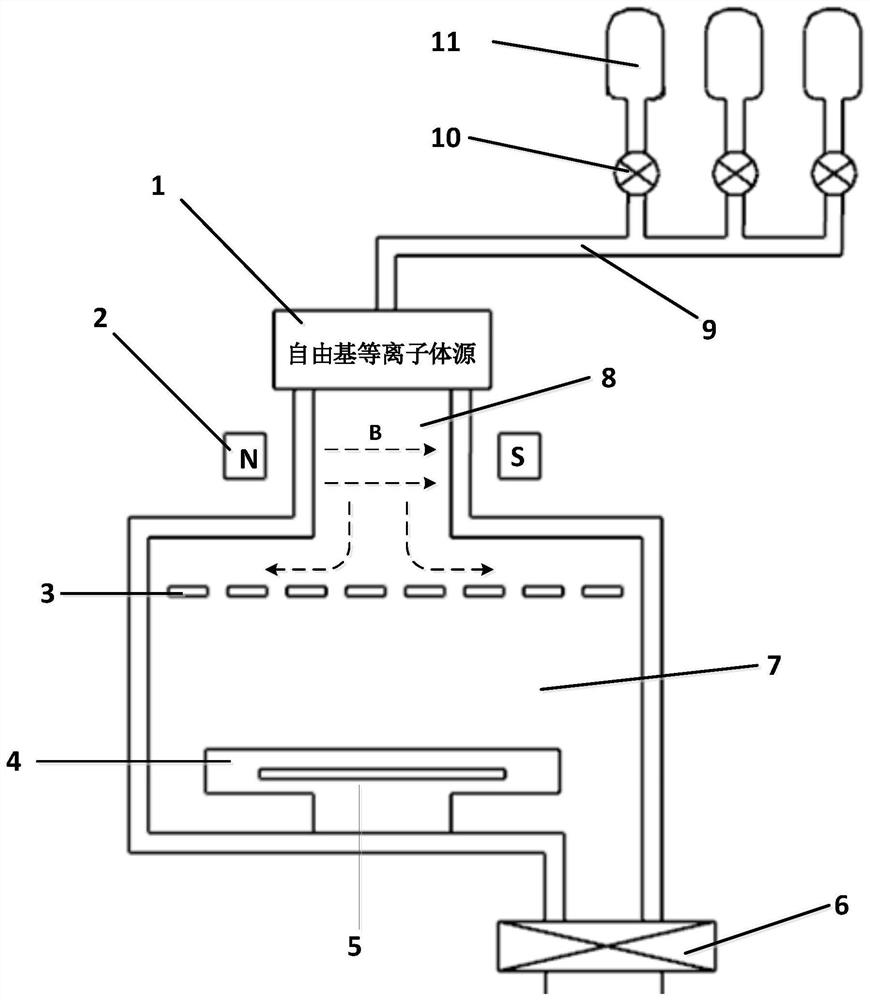

Method used

Image

Examples

Embodiment 1

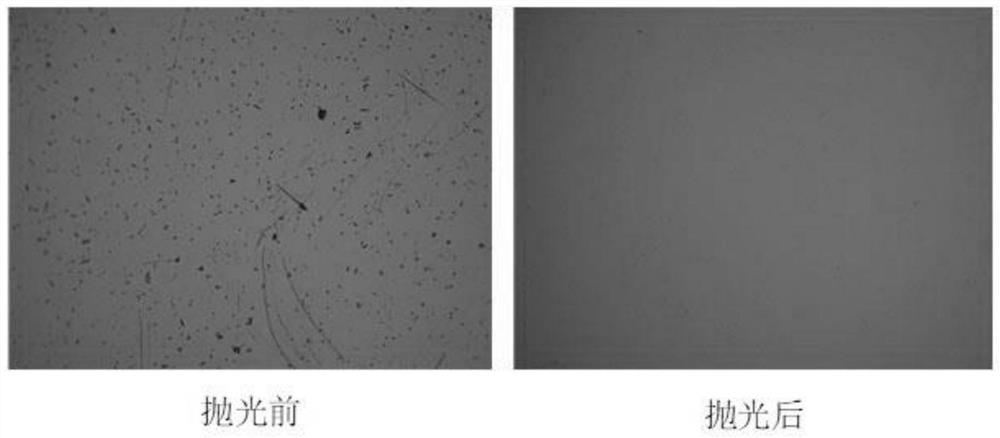

[0035] Polishing experiment of subsurface damaged layer of fused silica:

[0036] Step 1: Ultrasonic cleaning is performed on the fused silica sample to be tested, and the surface of the fused silica is immersed in 10% HF acid solution for 10 minutes to expose the subsurface damage layer, and the subsurface damage is observed with a microscope;

[0037] Step 2: Open the vacuum cover of the polishing chamber, place the fused silica on the polishing base, cover the vacuum cover, and use the exhaust system to reduce the vacuum degree of the polishing chamber to 10-3Pa;

[0038] Step 3: Fill in the working gas, carbon tetrafluoride 500sccm, oxygen 100sccm, use the voltage stabilization system to stabilize the vacuum at 50Pa, turn on the microwave plasma source, adjust the microwave power to 2000W, start glow discharge, and generate plasma. The device starts to work;

[0039] Step 4: Process for about 40 minutes, close the device, inflate, open the vacuum polishing chamber, take o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com