Strip-shaped electrode plate flue gas charging apparatus

A strip electrode and charging device technology, applied in the field of flue gas charging dust removal, can solve the problems of inability to set the working state, energy consumption, efficiency discount, etc., to increase the probability of mutual collision, reduce operating costs, and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

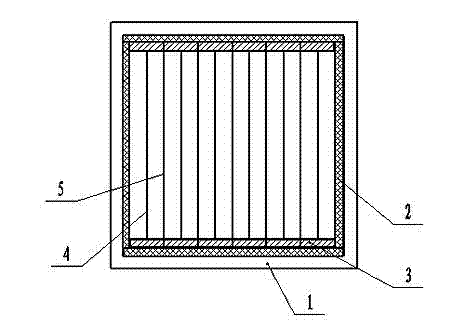

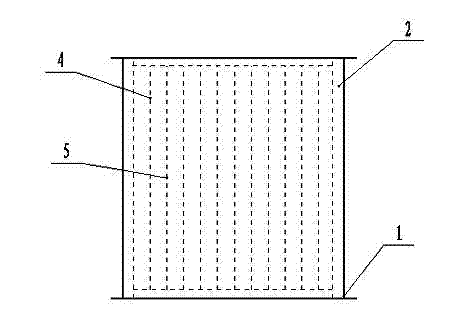

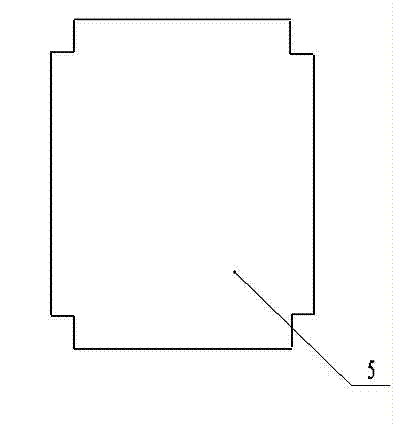

[0016] Such as Figure 1 to Figure 7 As shown, the strip-shaped electrode plate smoke charging device includes a shell 1, an insulating plate 2, a bracket plate 3, and an electrode plate 4. It is characterized in that four insulating plates 2 are installed around the inner wall of the square shell 1, and the inner walls of the upper and lower insulating plates 2 Each support plate 3 is installed; the support plate 3 is provided with a plurality of concave grooves 7 in parallel, and the electrode plates 4 are installed in the corresponding concave grooves 7 up and down; the shape of the electrode plates 4 is a plurality of parallel-arranged strip frames Combination; the bracket plate 3 is provided with a plurality of through grooves 8 in parallel, and the partition plate 5 is installed and fixed in the upper and lower corresponding through grooves 8, and the concave grooves 7 and the through grooves 8 are arranged at intervals.

[0017] The electrode plate 4 is evenly installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com