Two-phase integrated anaerobic reactor

An anaerobic reactor and reactor technology, applied in the field of anaerobic reactors, can solve the problems of increasing operation and maintenance costs, heat loss, increasing capital construction costs and floor space, etc., so as to avoid sludge sedimentation, and reduce construction costs and maintenance costs. , the effect of improving the reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

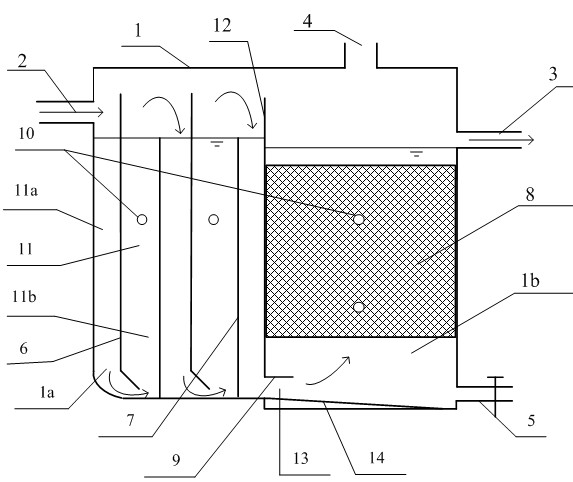

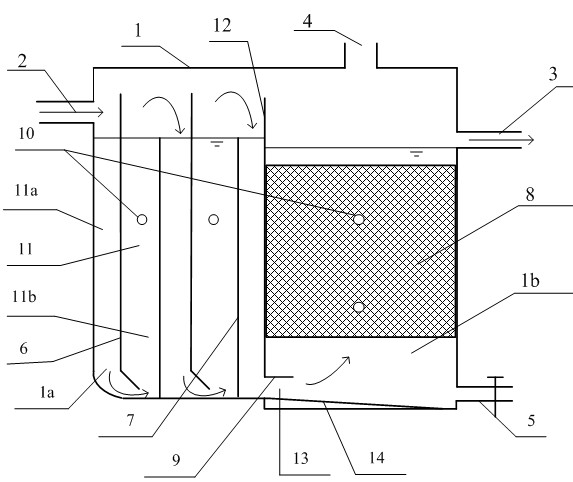

[0016] Such as figure 1 The two-phase integrated anaerobic reactor shown is composed of reactor 1, water inlet 2, water outlet 3, gas collection port 4, mud discharge port 5, deflector 6, partition 7, filler 8 and drainage plate 9, etc. constitute. The reactor 1 is divided into two left and right cavities by the partition plate 12, the left cavity is the hydrolytic acidification tank 1a, and the right cavity is the methanogenic tank 1b. The water inlet 2 is arranged on the upper part of the hydrolytic acidification tank 1a, the water outlet 3 is arranged on the upper part of the methanogenic tank 1b, and the water inlet 2 is higher than the water outlet 3. The gas collection port 4 is set on the top of the methanation pool 1b, and the mud discharge port 5 is set on the bottom of the methanation pool 1b.

[0017] The hydrolytic acidification tank 1a is a re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com