Method for increasing yield and injection of low-permeability oil field

A low-permeability, oilfield technology, used in earth-moving drilling, fluid production, wellbore/well components, etc., can solve the problems of high water injection pressure, small limit well spacing, shortened well spacing, etc., and achieve long injection distance and injection aperture. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

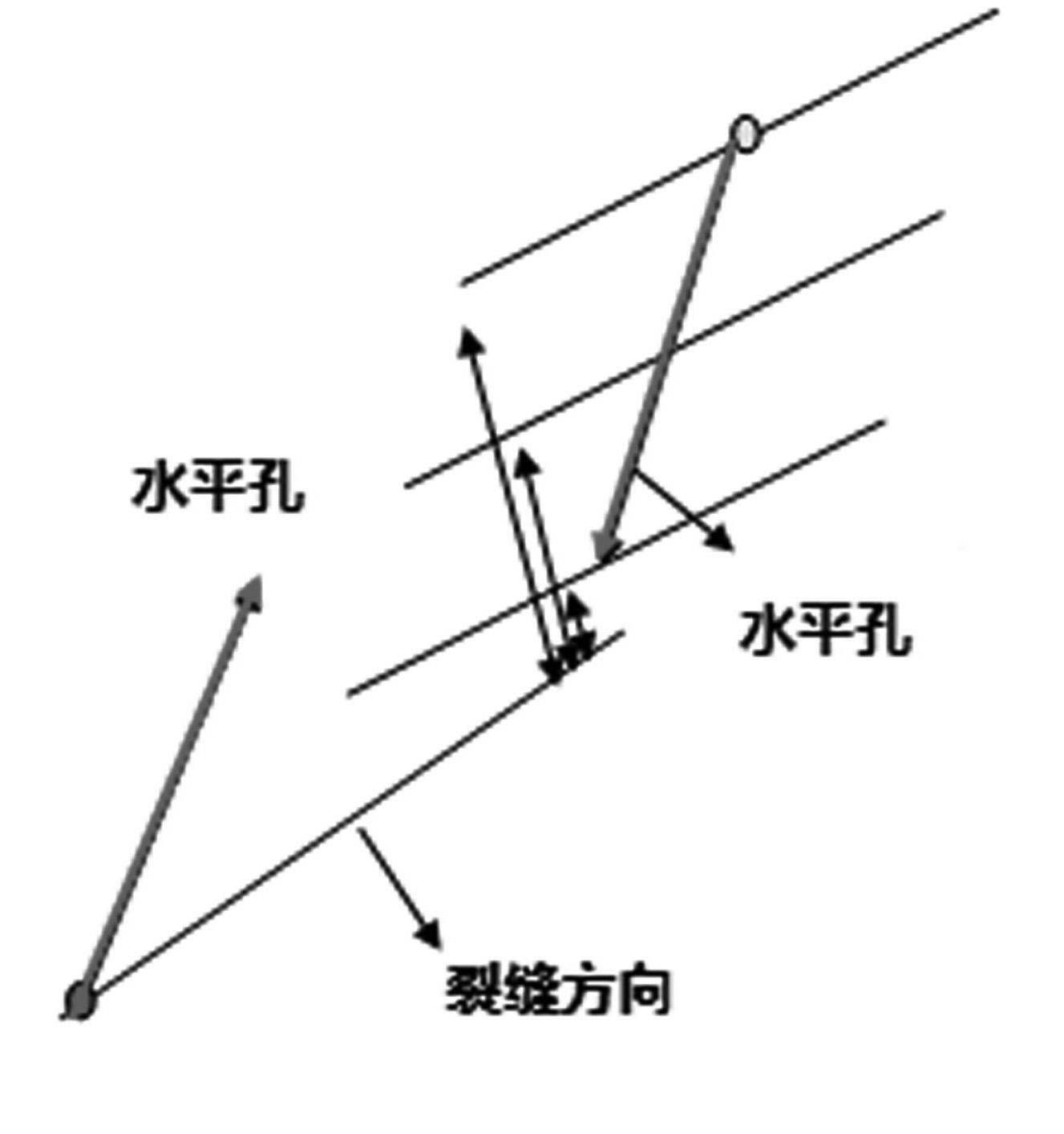

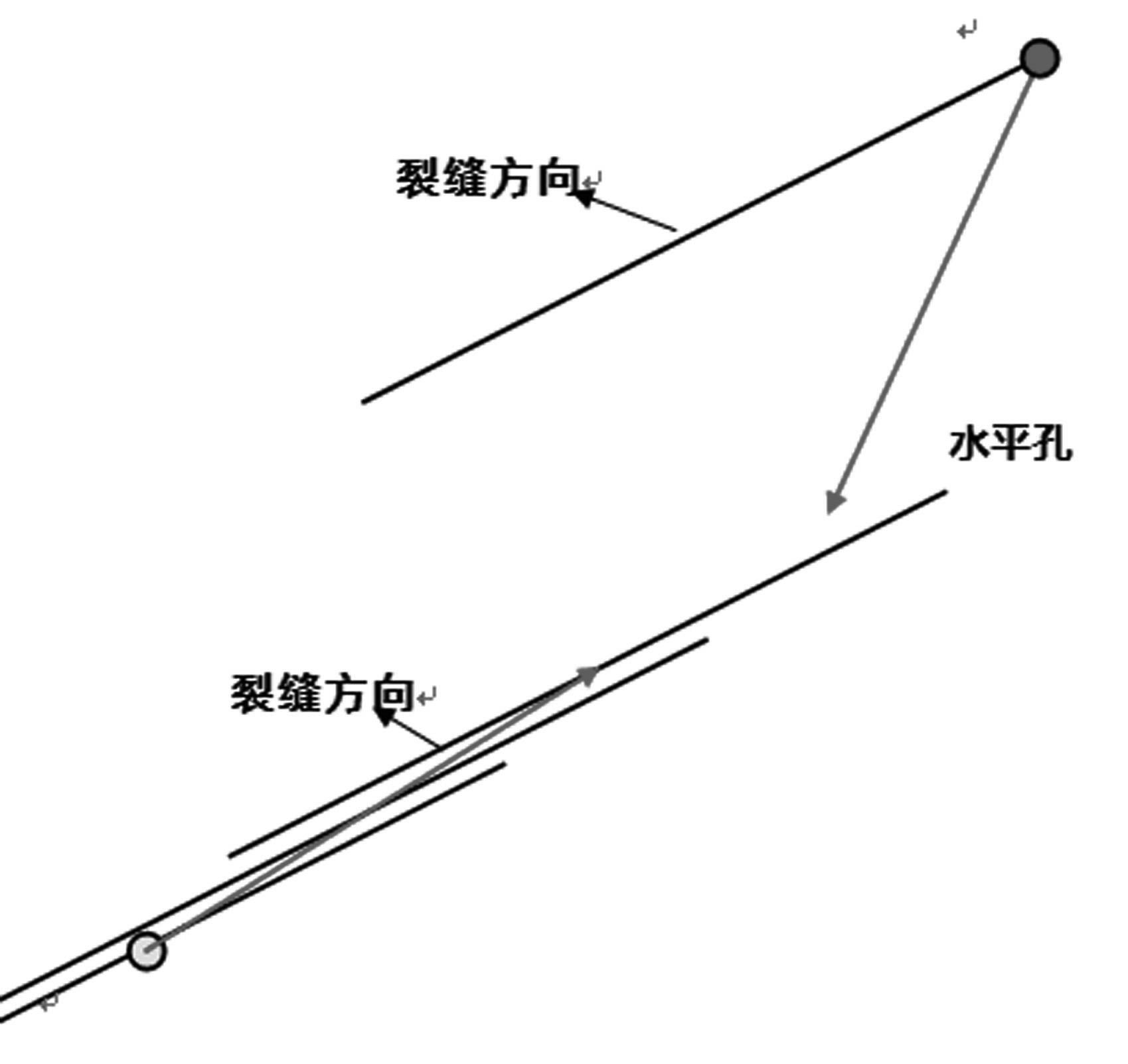

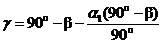

[0044] Wells with good reservoir connectivity but poor physical properties and prominent water injection problems were selected to carry out fracturing tests after hydraulic deep penetration perforation. The established formula is used for programming calculation, and the maximum distance of the horizontal perforation in the oil layer is obtained under different perforation directions and formation dip angles. Finally, the test layers are determined to be the main layers PI2 and PI6, and the perforation directions are NE15° and NE45°, the perforation length is 100m, and the horizontal hole spraying of 5 holes is completed in two directions first.

[0045] ① Determination of parameters: Considering the impact of horizontal holes on the crack initiation position, numerical simulation is performed on different crack initiation positions to optimize the fracture parameters. The half-length of the main fracture is designed to be 100m, but at the same time considering the possible f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com