Disc-type rod fastening rotor structure for heavy-duty gas turbine

A tie-rod rotor and gas turbine technology, which is applied in the direction of gas turbine devices, mechanical equipment, jet propulsion devices, etc., can solve the problems of low assembly efficiency and affecting the dynamic balance of rotors, and achieve high assembly efficiency, high centering accuracy and repeatability, good effect on neutral

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

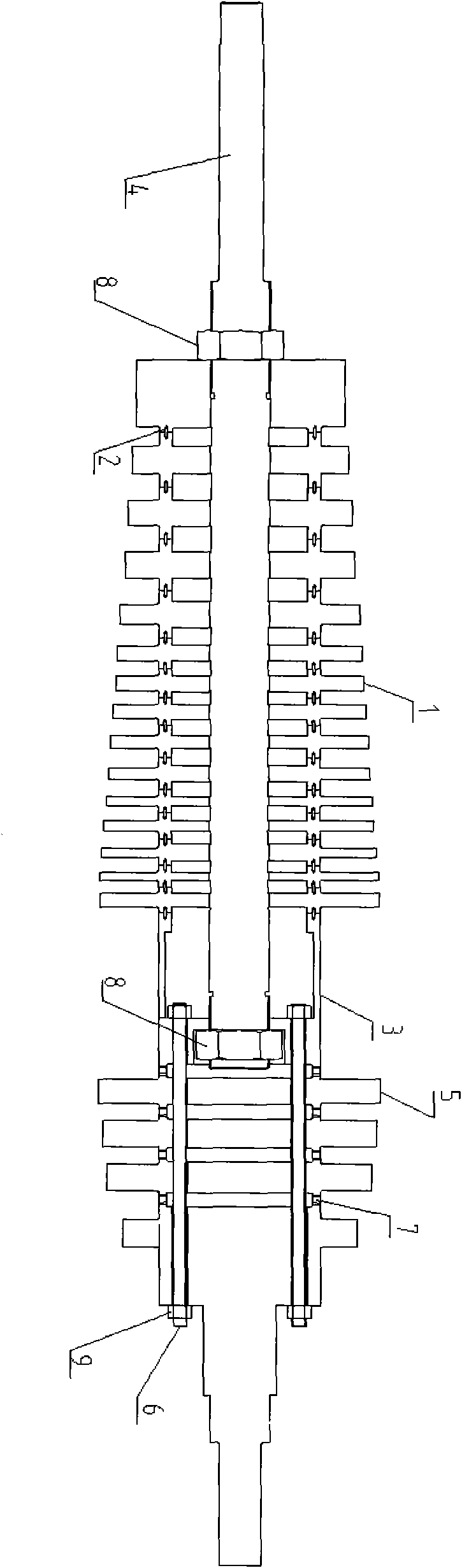

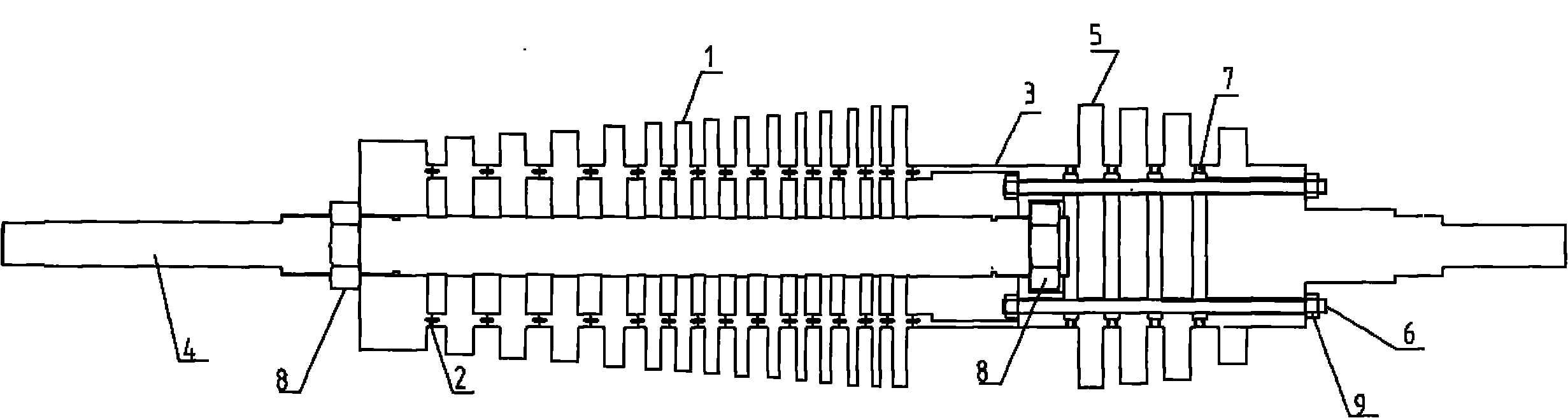

[0012] The structural principle and working principle of the present invention will be described in further detail below in conjunction with the accompanying drawings.

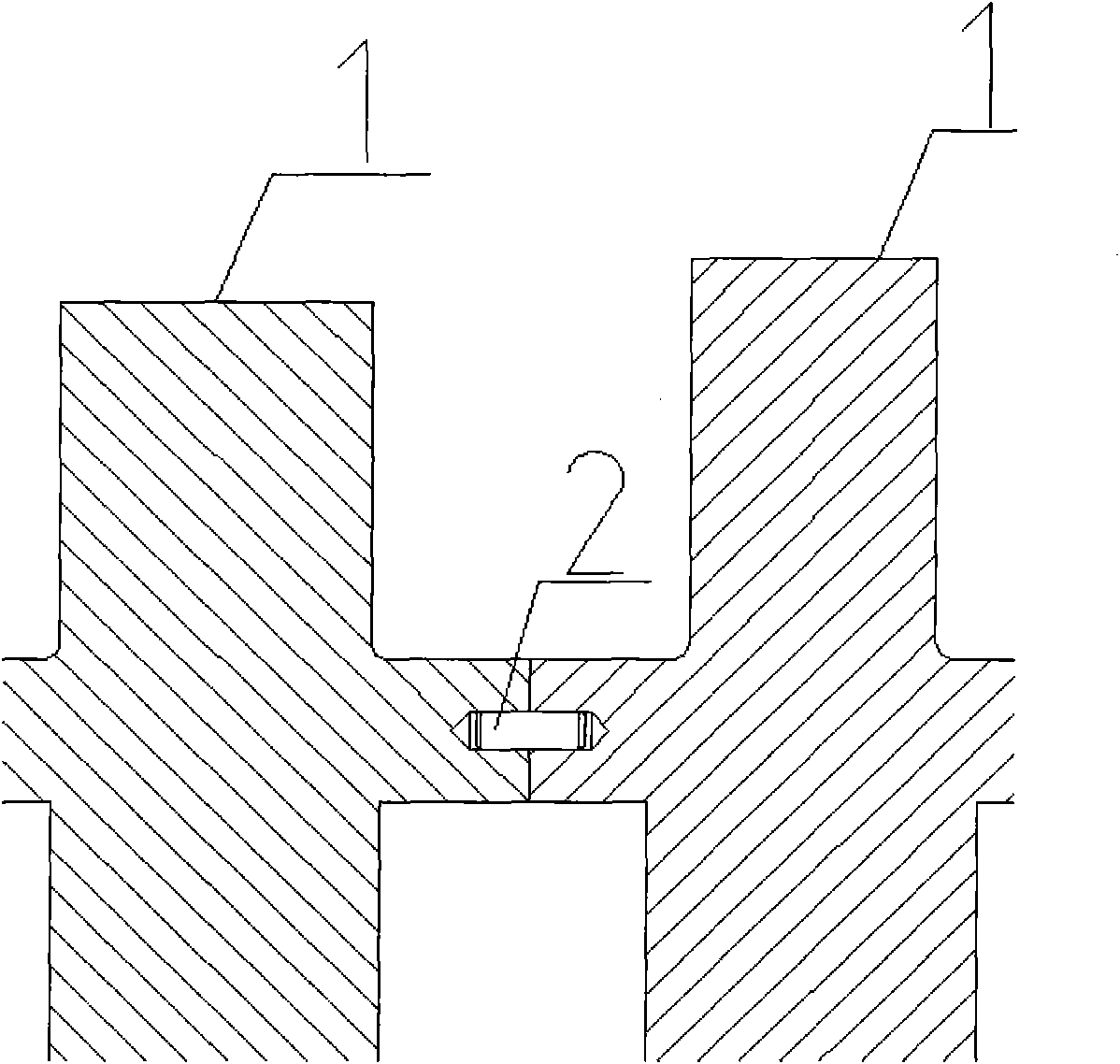

[0013] refer to figure 1 and figure 2 , a disc tie-rod rotor structure for heavy-duty gas turbines, including compressor discs 1 with 10 or more stages in the compressor section, the compressor discs 1 are connected by axial transmission and twist pins 2, and finally One end of the first-stage compressor disc 1 and the middle combustion chamber section 3 is connected by an axial twist pin 2, and the central tie rod 4 passes through the central holes of the compressor discs 1 and the middle combustion chamber section 3 of each stage, and passes through the pre- Tighten the central tie rod 4 and the central tie rod nut 8 to connect the compressor discs 1 of each stage of the compressor section and the intermediate combustion chamber section 3 into a whole, and the other end of the intermediate combustion chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com