Fluid pressurizing machine

A supercharger and fluid technology, applied in the direction of liquid variable volume machinery, mechanical equipment, machines/engines, etc., can solve the problems of a large number of sealing rings, poor high-pressure fluid bearing capacity, poor sealing performance, etc., and meet the fluid cleaning requirements. Low, simple and reliable control, the effect of simple function structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

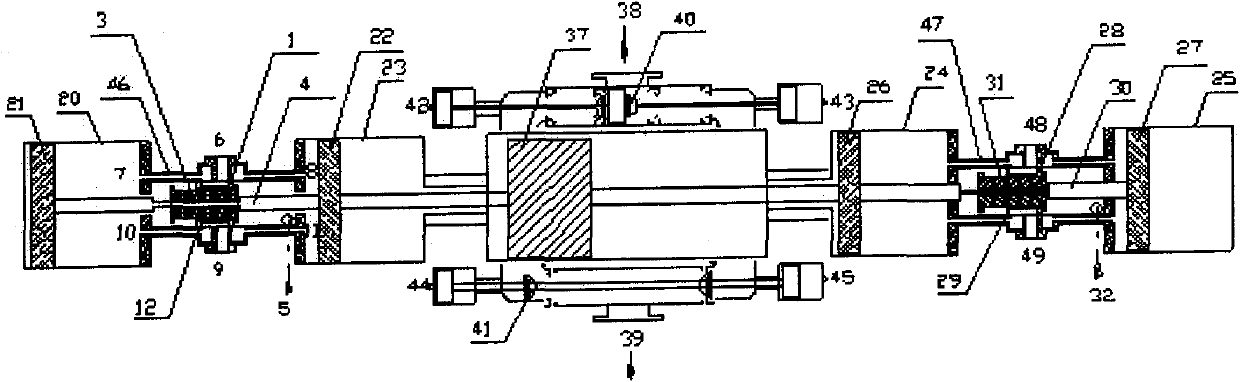

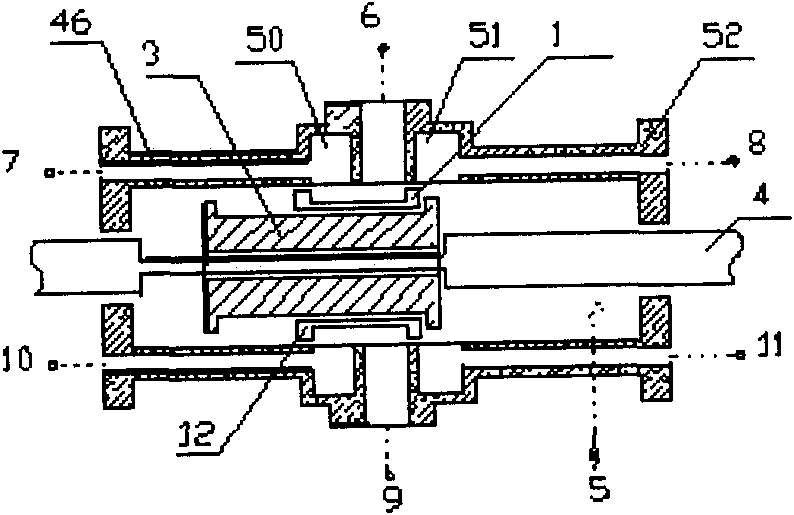

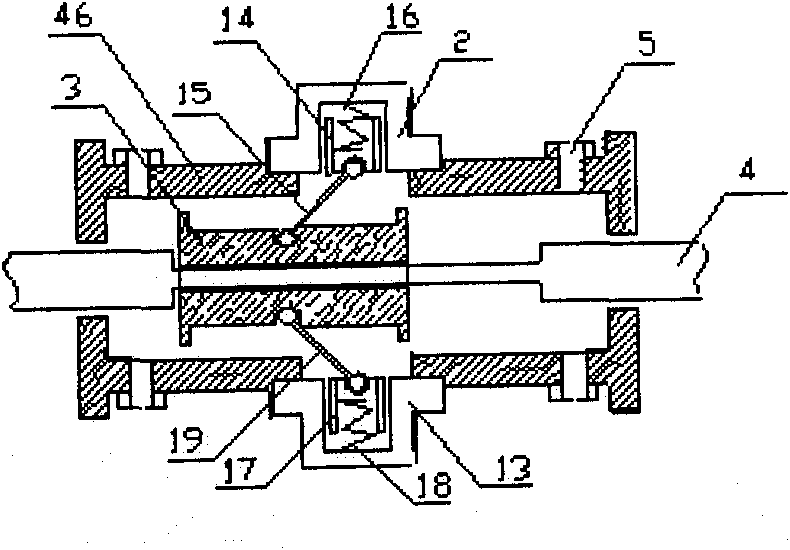

[0011] figure 1 A kind of fluid supercharging machine, comprises cylindrical cylinder 20, 23, 24, 25, piston 21, 22, 26, 27, reversing fluid valve 46, 47, is characterized in that: described reversing fluid valve is at least Two, at least one end of each reversing fluid valve is provided with a cylindrical cylinder, each cylindrical cylinder is provided with a piston and a drive chamber, the piston in the cylindrical cylinder is connected by a piston rod, and the reversing fluid valve Power fluid inlets 5, 32 and power fluid outlets 6, 9, 48, 49 are provided. The reversing fluid valve is also provided with a control signal port connected to the power fluid inlet or power fluid outlet. The drive cavity is connected. The working plunger 37 of the actuator is connected to the piston rod, and the cavities on both sides of the workin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com