Adjustable mechanical sealing structure for pump

A technology for mechanical seals and pumps, applied in mechanical equipment, pumps, pump components, etc., it can solve the problems of insufficient cooling, axial adjustment of mechanical seals, and short service life of dynamic and static rings, so as to enhance the cooling effect. , the sealing state is stable, and the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

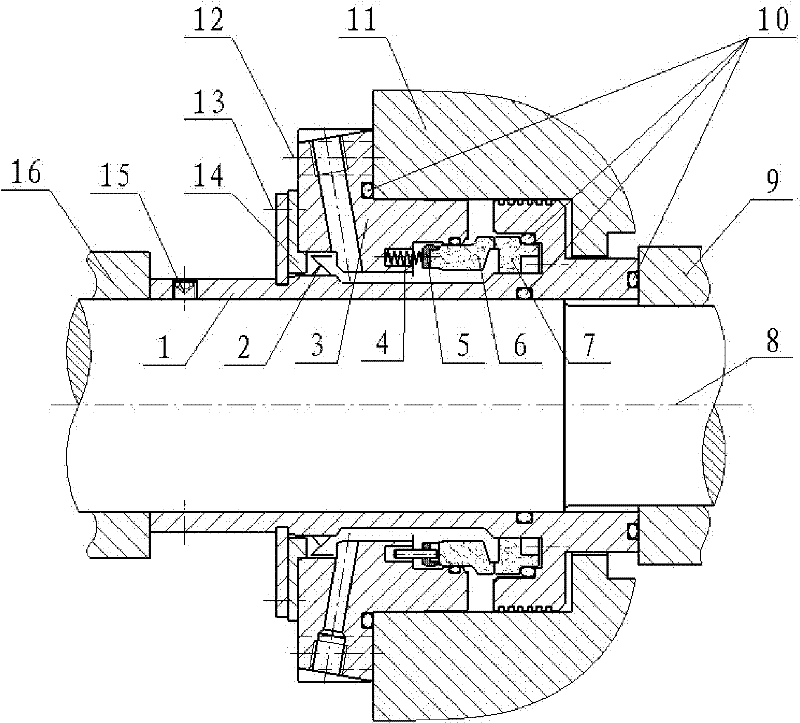

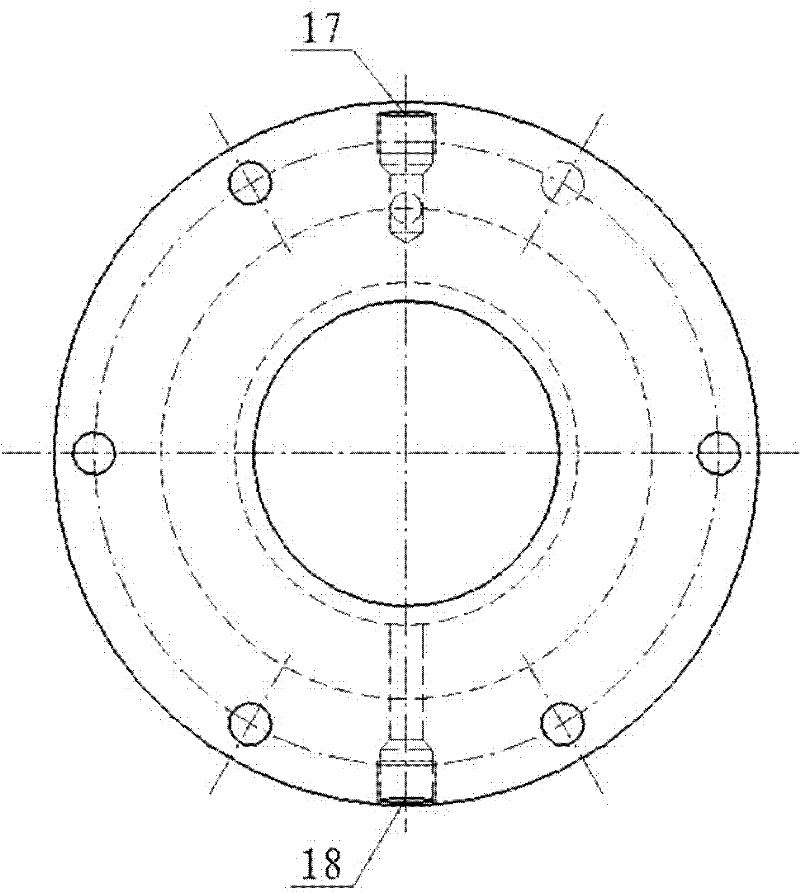

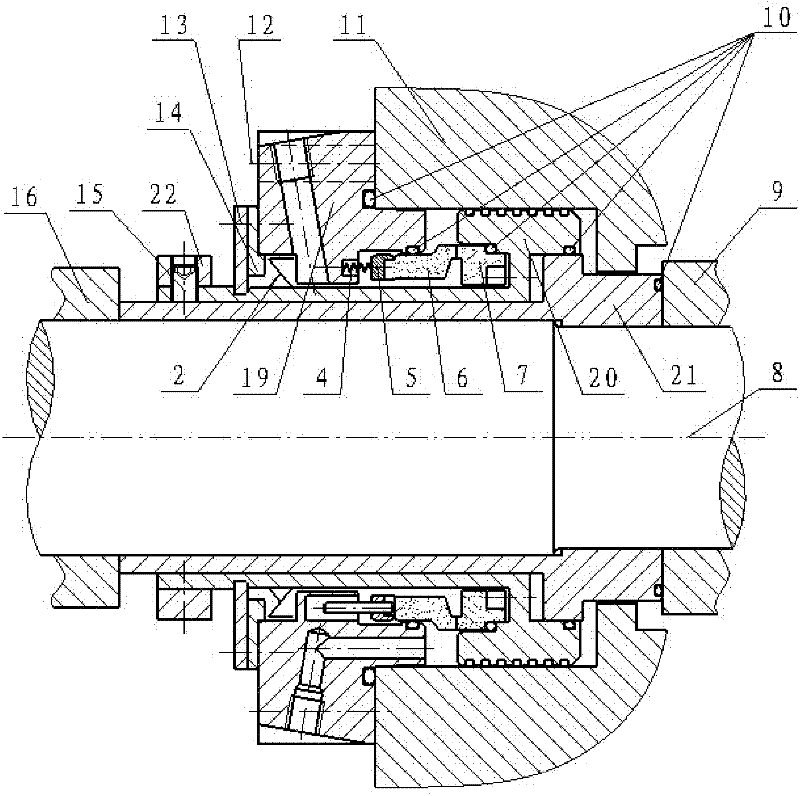

[0025] like image 3 and Figure 4As shown, an adjustable mechanical seal for pumps includes a moving ring 7, a static ring 6, a push ring 5, a spring 4, a skeleton oil seal 2, an oil seal gland 14, set screws 15, hexagon socket bolts and positioning clips 13 , bolts 12 and O-ring 10; peripheral equipment includes: pump shaft 8, transmission parts 16, mechanical seal pump cover 11, impeller 9; it also includes connecting flange 19, drive ring 22, inner shaft sleeve 21 and outer shaft sleeve 20. Among them, the inner shaft sleeve 21 and the outer shaft sleeve 20 are fitted with sleeves, and the distance between the two can be adjusted axially from -5mm to +5mm. After the inner shaft sleeve 21 is installed on the pump shaft 8, its front and rear are pushed against the transmission parts 16 and impeller 9, so that the inner shaft sleeve 21 and the transmission shaft structure are connected as one; the outer shaft sleeve 20 inherits the advantages of the prior art, and the part i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com