Structure controllable phosphorylated polymer composite film used for vanadium battery and preparation method thereof

A technology of polymer and vanadium batteries, which is applied in fuel cell parts, structural parts, regenerative fuel cells, etc., can solve the problems of high vanadium ion permeability, short service life, and high price, and achieve high voltage efficiency and Energy conversion efficiency, cost reduction, and the effect of promoting the commercialization process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

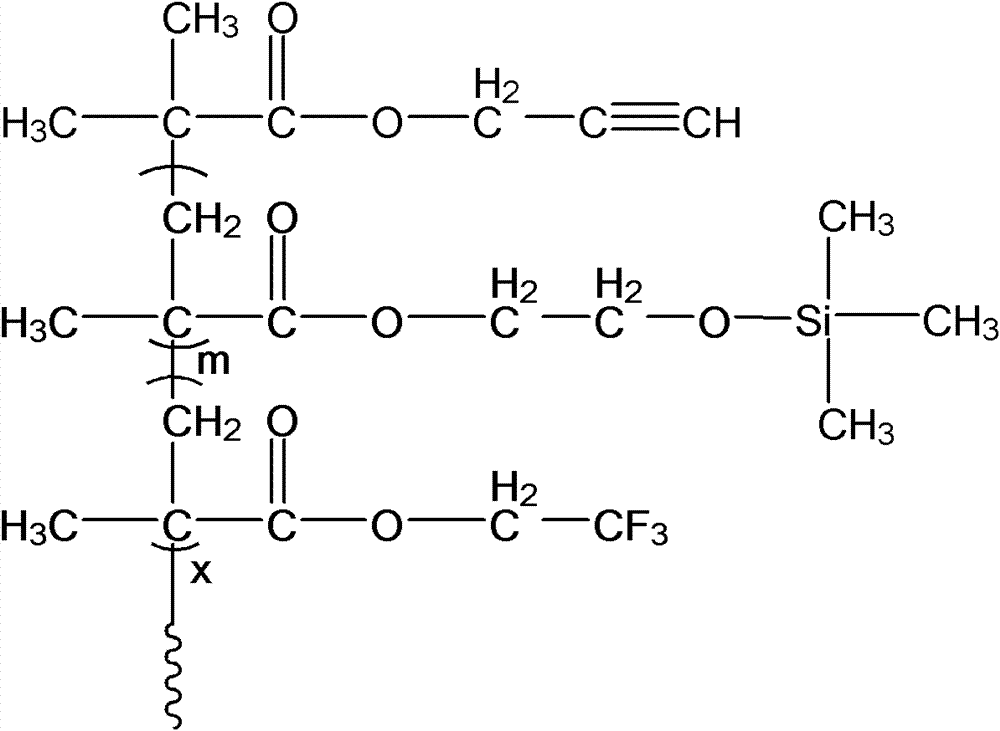

[0044] (1) Add 10g trifluoroethyl methacrylate, 10g trimethylchlorosilane-terminated hydroxyethyl methacrylate, 0.2g 2-bromoisobutyric acid propynyl alcohol, 0.3g pentafluoroethyl methacrylate to a 100ml round bottom flask Methyldiethylenetriamine and 50ml N,N-dimethylformamide, the mixed system was dissolved and argon was bubbled for 30min, then deoxygenated, and then the solution was transferred to a 100ml round bottom flask containing 0.2g cuprous chloride Polymerization reaction was carried out at 75°C for 8h, the reaction product was precipitated in water, washed with water and then washed with n-hexane, and then vacuum-dried at 55°C for 12h to constant weight to obtain an alkynyl-containing copolymer; the structure of an alkynyl-containing copolymer Such as figure 1 shown;

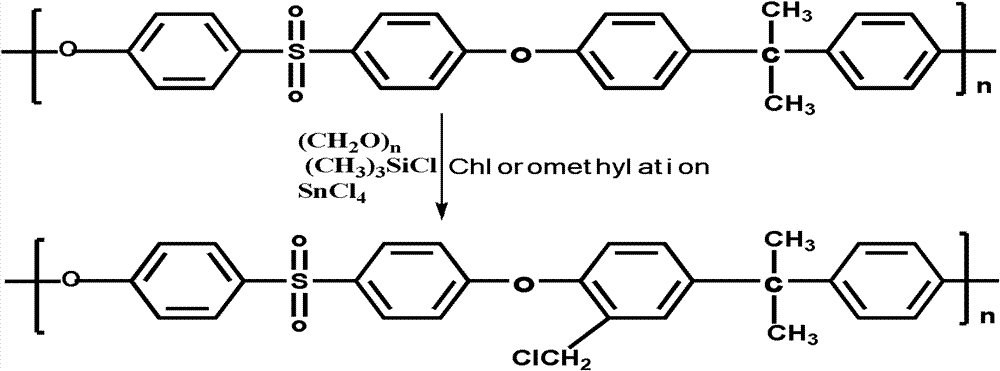

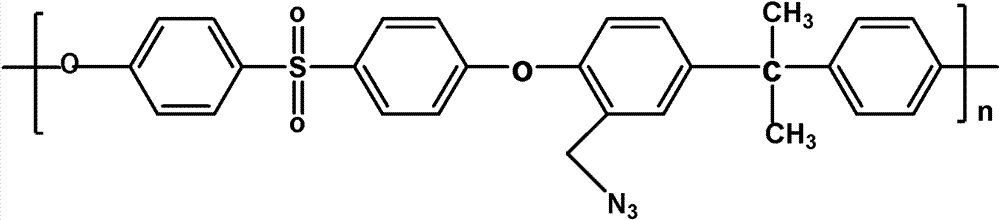

[0045] (2) Add 14.88g polysulfone and 750ml chloroform in a 1000ml round bottom flask, stir at room temperature to dissolve the polysulfone, then add 10g paraformaldehyde, 0.8ml tin tetrachloride an...

Embodiment 2

[0055] Same as Example 1, except that 35 g of trifluoroethyl methacrylate and 30 g of trimethylchlorosilane-terminated hydroxyethyl methacrylate were added in the reaction of step (1). The phosphorylated polymer composite membrane obtained in this embodiment has a structure as shown in formula (I), wherein m is 18, x is 22, and n is 65.

Embodiment 3

[0057] Same as Example 1, except that 30 g of trifluoroethyl methacrylate and 10 g of trimethylchlorosilane-capped hydroxyethyl methacrylate were added to the reaction in step (1). The phosphorylated polymer composite membrane obtained in this embodiment has a structure as shown in formula (I), wherein m is 6, x is 18, and n is 65.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com