Method for purifying aluminum ammonium sulfate

A technology of aluminum ammonium sulfate and aluminum ammonium sulfate hydrate, which is applied in the direction of aluminum sulfate, aluminum sulfur compounds, solution crystallization, etc., can solve the problems of complex treatment process, large amount of extraction agent, introduction, etc., and achieve the effect of simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

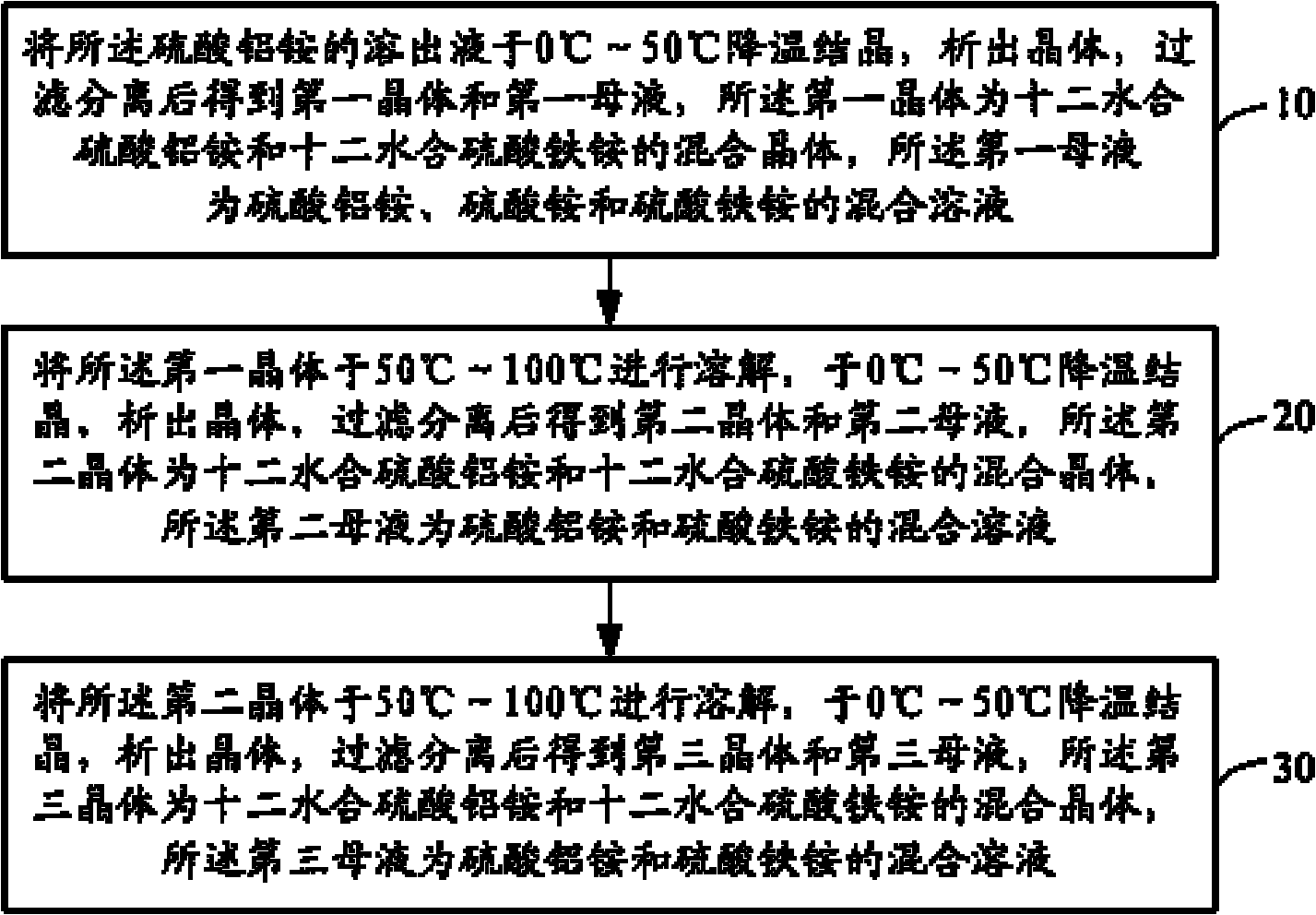

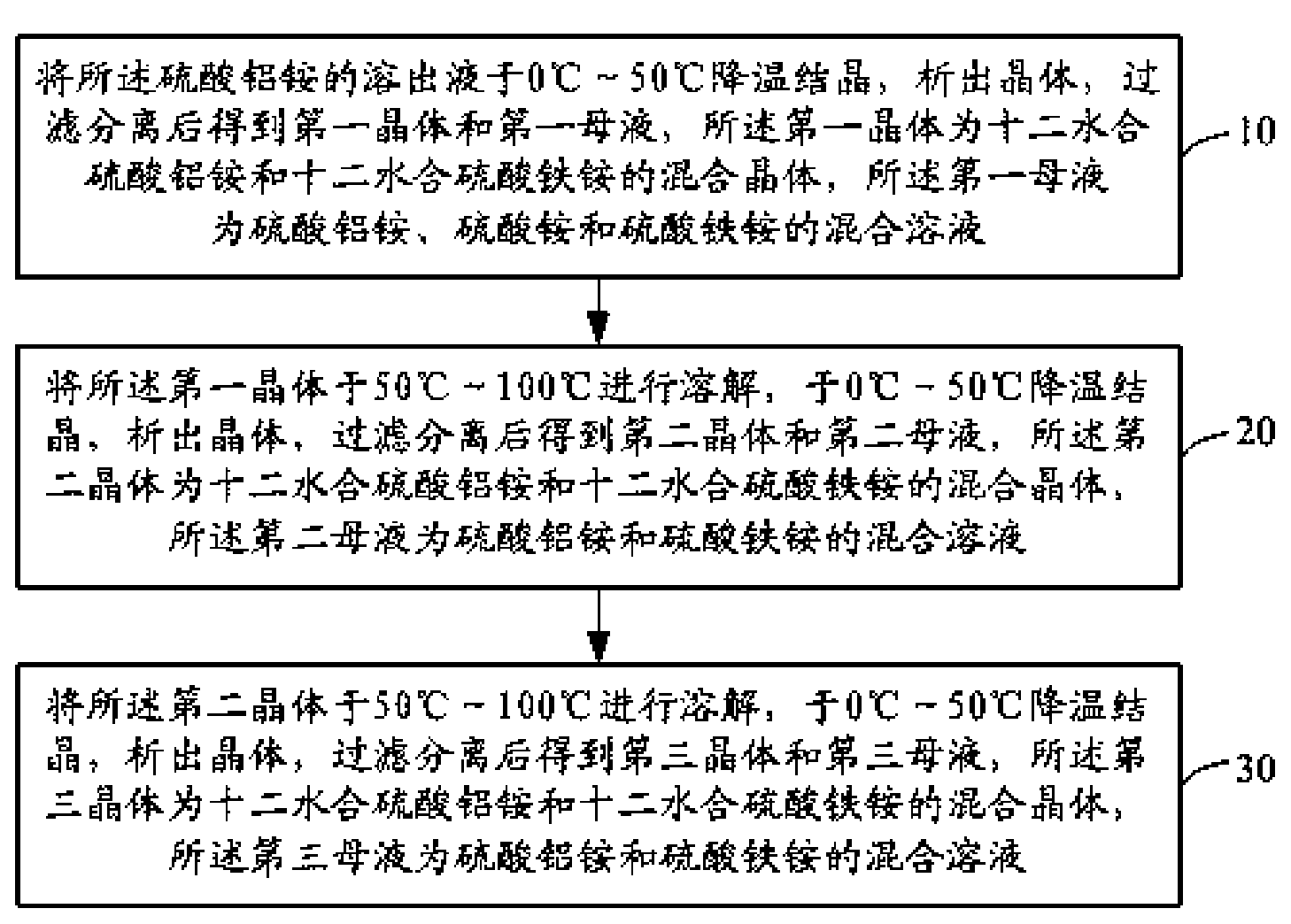

Method used

Image

Examples

Embodiment 1

[0034] The mixed ingredients of fly ash and ammonium sulfate are sintered, and the obtained sintered solid is dissolved. The main components and respective concentrations of the dissolved liquid are aluminum ammonium sulfate (NH 4 Al(SO 4 ) 2 ) 106.9g / L, ferric ammonium sulfate (NH 4 Fe(SO 4 ) 2 )8.5g / L, ammonium sulfate ((NH 4 ) 2 SO 4 ) 161.4g / L, etc., the raw material solution was cooled to 20°C, and the first crystal was precipitated. The first crystals dissolve at 90°C at a concentration of ammonium aluminum sulfate (NH 4 Al(SO 4 ) 2 )502g / L, ferric ammonium sulfate (NH 4 Fe(SO 4 ) 2 ) 6.8g / L, the solution was cooled to 20°C for the second crystallization, and the second crystal was obtained after filtration and separation. The second crystal is dissolved in water at 90°C with a concentration of ammonium aluminum sulfate (NH 4 Al(SO 4 ) 2 )505g / L, ferric ammonium sulfate (NH 4 Fe(SO 4 ) 2 ) 0.8g / L, this solution is cooled to 20 ℃, carries out the third ...

Embodiment 2

[0036] The mixed ingredients of fly ash and ammonium sulfate are sintered, and the obtained sintered solid is dissolved. The main components and respective concentrations of the dissolved liquid are aluminum ammonium sulfate (NH 4 Al(SO 4 ) 2 ) 120.1g / L, ferric ammonium sulfate (NH 4 Fe(SO 4 ) 2 )5.5g / L, ammonium sulfate ((NH 4 ) 2 SO 4 ) 41.4g / L, etc., the raw material solution was cooled to 40°C, and the first crystal was precipitated. The first crystals dissolve at 80°C at a concentration of ammonium aluminum sulfate (NH 4 Al(SO 4 ) 2 ) 402g / L, ferric ammonium sulfate (NH 4 Fe(SO 4 ) 2 ) 2.8g / L, the solution was cooled to 40°C for the second crystallization, and the second crystal was obtained after filtration and separation. The second crystal is dissolved in water at 80°C with a concentration of ammonium aluminum sulfate (NH 4 Al(SO 4 ) 2 ) 403g / L, ferric ammonium sulfate (NH 4 Fe(SO 4 ) 2 ) 0.4g / L, this solution is cooled to 40 ℃, carries out the third...

Embodiment 3

[0038] The mixed ingredients of fly ash and ammonium sulfate are sintered, and the obtained sintered solid is dissolved. The main components and respective concentrations of the dissolved liquid are aluminum ammonium sulfate (NH 4 Al(SO 4 ) 2 ) 101.7g / L, ferric ammonium sulfate (NH 4 Fe(SO 4 ) 2 )3.5g / L, ammonium sulfate ((NH 4 ) 2 SO 4 ) 60.9g / L, etc., the raw material solution was cooled to 30°C, and the first crystal was precipitated. The first crystals dissolve at 70°C at a concentration of ammonium aluminum sulfate (NH 4 Al(SO 4 ) 2 ) 299g / L, ferric ammonium sulfate (NH 4 Fe(SO 4 ) 2 ) 1.3g / L, the solution was cooled to 30°C for the second crystallization, and the second crystal was obtained after filtration and separation. The second crystal is dissolved in water at 70°C with a concentration of ammonium aluminum sulfate (NH 4 Al(SO 4 ) 2 )307g / L, ferric ammonium sulfate (NH 4 Fe(SO 4 ) 2 ) 0.1g / L, the solution was cooled to 30°C, and the third crystall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com