Aqueous chromium-free surface treatment solution for combining color coating pretreatment and base paint coating of galvanized plate

A surface treatment liquid and pretreatment technology, which is applied in the coating process of metal materials, etc., to achieve the effects of simplifying the color coating process, improving corrosion resistance, excellent corrosion resistance and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The surface of the galvanized sheet is chemically degreased with a degreasing solution, rinsed with tap water, rinsed with deionized water, and dried with hot air before pretreatment.

[0031] Pretreatment liquid temperature: room temperature, passivation time: 15s, passivation method: dip coating, spray coating, roller coating are all available, drying temperature: 80-100 ℃ drying.

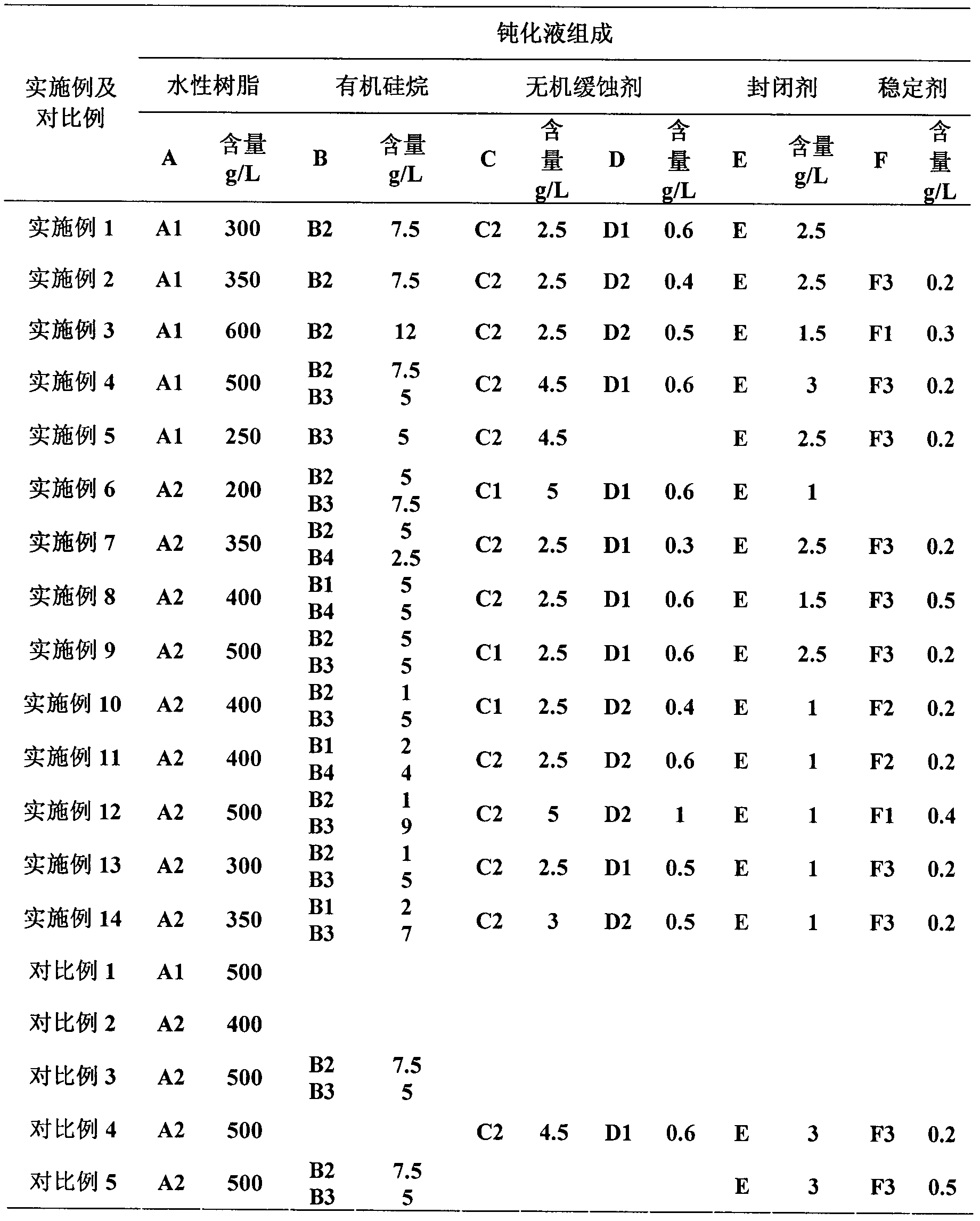

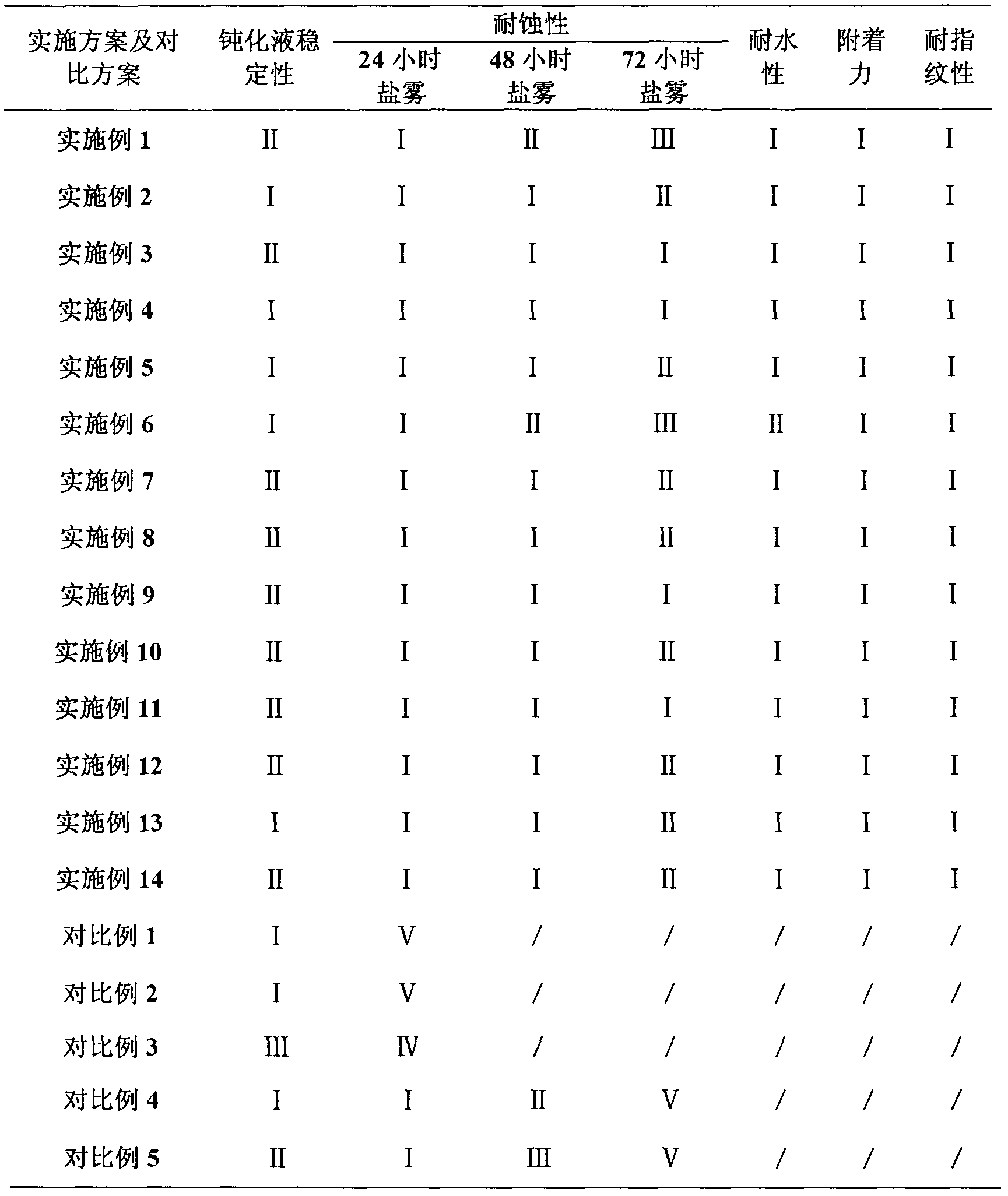

[0032] The compositions of the surface treatment liquids used in the examples and comparative examples of the present invention are shown in Table 1.

[0033] Table 1 surface treatment liquid composition

[0034]

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com