Organic and inorganic composite aqueous surface treatment liquid for color coating pretreatment of galvanized sheet

A surface treatment liquid and composite water-based technology, which is applied to the surface coating liquid device, coating, metal material coating process, etc., to achieve the effect of improving corrosion resistance, simplifying the color coating process, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

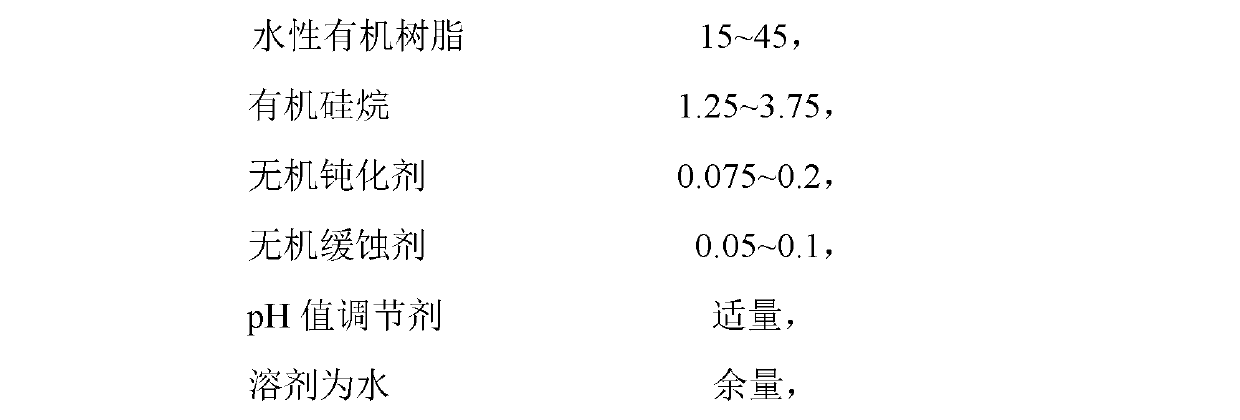

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Use water-based polyurethane with an effective content of 150g (solid content is 25wt%), 12.5g organosilane, 2g inorganic passivator, 1g inorganic corrosion inhibitor and the rest of the water and inorganic acid to prepare a pH value of 3 ~4 of 1000g treatment solution. Among them, organosilane is prepared from γ-glycidyl etheroxypropyltrimethoxysilane and N-(β-aminoethyl)-γ-aminopropyltriethoxysilane according to the mass ratio of effective content of 4:1. to make. The inorganic passivation agent is zirconium sulfate and cobalt sulfate, prepared according to the mass ratio of effective content of 1:1, and the inorganic acid is nitric acid.

[0028] The implementation process is simple, and the prepared passivation solution has good stability. In an aqueous solution of 5% NaCl, the corrosion potential Ecorr obtained by electrochemical testing is -1.0390V, and the polarization resistance is 0.405 kΩ / cm 2 , the corrosion current is 128.8A / cm 2 . The area o...

Embodiment 2

[0029] Embodiment 2: use the water-based polyurethane (solid content is 25wt%) that effective content is 300g, 25g organosilane, 0.75g inorganic passivation agent, 0.5g inorganic corrosion inhibitor and the water of remainder and inorganic acid to prepare pH value 1000g treatment solution for 3~4. Among them, organosilane is prepared from γ-glycidyl etheroxypropyltrimethoxysilane and N-(β-aminoethyl)-γ-aminopropyltriethoxysilane according to the mass ratio of effective content of 3:1. to make. The inorganic passivation agent is zirconium sulfate and cobalt sulfate, prepared according to the mass ratio of the effective content of 1:2, and the inorganic acid is nitric acid.

[0030] The implementation process is simple, and the prepared passivation solution has good stability. In an aqueous solution of 5% NaCl, the corrosion potential Ecorr obtained by electrochemical testing is -0.6283V, and the polarization resistance is 112.9 kΩ / cm 2 , the corrosion current is 0.4279A / cm ...

Embodiment 3

[0031] Embodiment 3: use the water-based polyurethane (solid content is 25wt%) that effective content is 300g, 25g organosilane, 0.75g inorganic passivation agent, 0.75g inorganic corrosion inhibitor and the water of remainder and inorganic acid to prepare pH value 1000g treatment solution for 3~4. Among them, organosilane is prepared from γ-glycidyl etheroxypropyltrimethoxysilane and N-(β-aminoethyl)-γ-aminopropyltriethoxysilane according to the mass ratio of effective content of 7:1. to make. The inorganic passivation agent is zirconium sulfate and cobalt sulfate, prepared according to the mass ratio of the effective content of 2:1, and the inorganic acid is sulfuric acid.

[0032] The implementation process is simple, and the prepared passivation solution has good stability. In an aqueous solution of 5% NaCl, the corrosion potential Ecorr obtained by electrochemical testing is -1.0365V, and the polarization resistance is 0.291 kΩ / cm 2 , the corrosion current is 130A / cm ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion potential | aaaaa | aaaaa |

| corrosion potential | aaaaa | aaaaa |

| corrosion potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com