Bushing for pipe joint and pipe joint adopting bushing

A pipe joint and joint connection technology, which is applied in the direction of pipe/pipe joint/fitting, sleeve/socket connection, passing components, etc., can solve the problems of endangering human health, health hazards, health hazards, etc., to increase friction, Effect of increasing pressure and ensuring airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

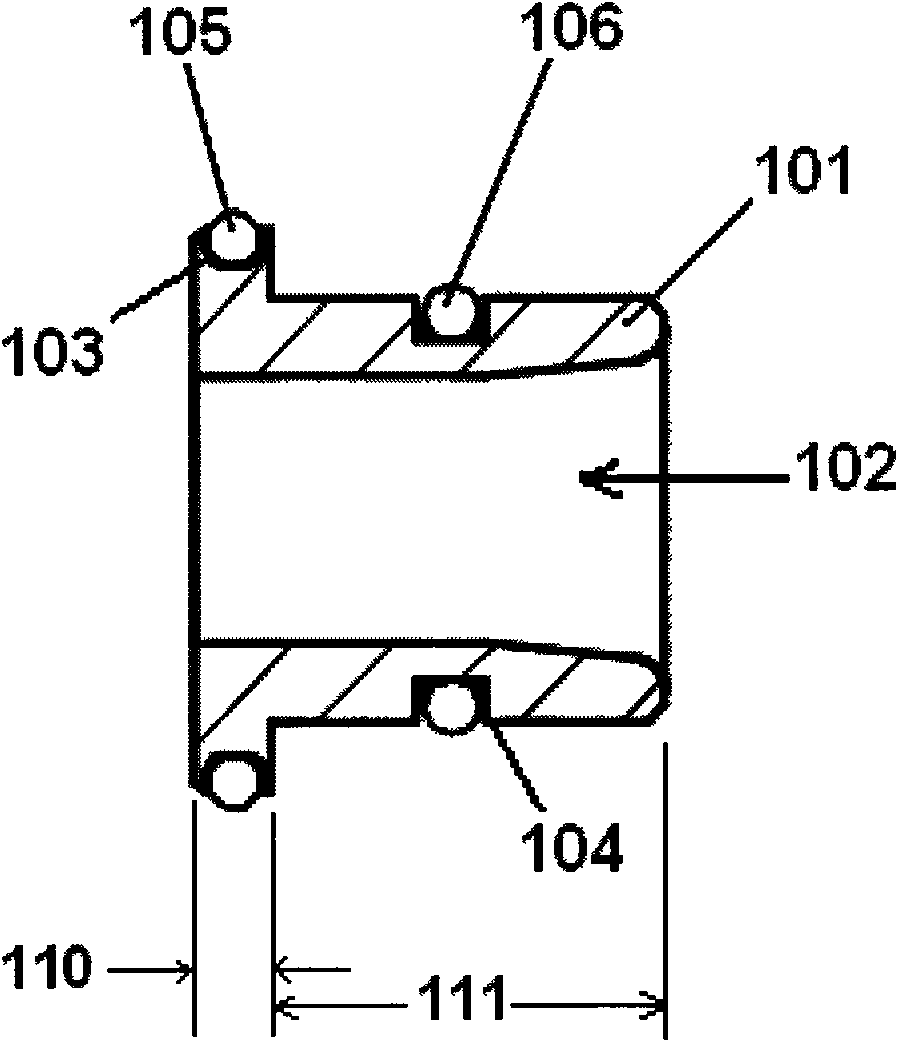

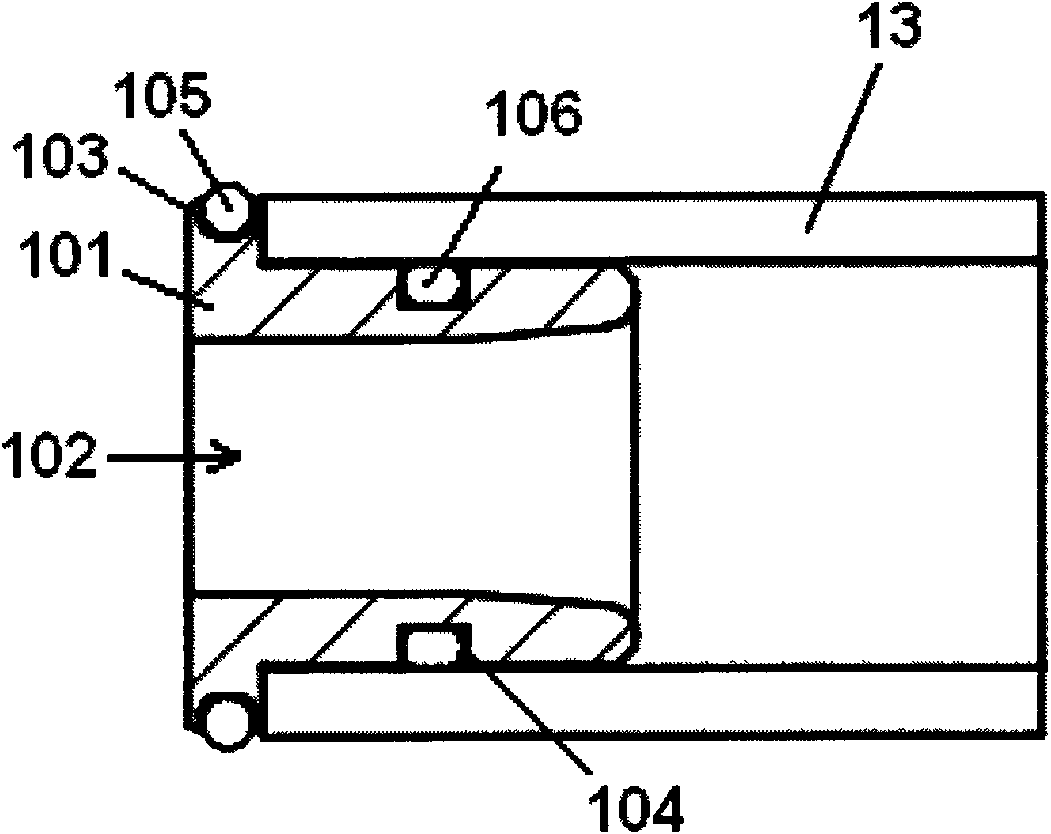

[0046] Such as figure 1 A bushing for a pipe joint, comprising a bushing body 101 with an axial channel 102 inside, the bushing body 101 includes a joint connection section 110 for docking with a pipe joint, and a pipe connection section for docking with a pipe 111. A bushing flange is provided on the peripheral outer wall of the joint connection section 110.

[0047] A first O-ring 105 is provided on the joint connection section 110 , and a second O-ring 106 is provided on the pipeline connection section 111 .

[0048] Wherein, the first positioning structure of the first O-ring 105 is provided on the circumferential outer wall of the joint connecting section 110, and the second O-ring is provided on the circumferential outer wall of the pipeline connecting section. The second positioning structure of 106, the first positioning structure is the first groove 103 arranged in the circumferential direction, the second positioning structure is the second groove 104 arranged in th...

Embodiment 2

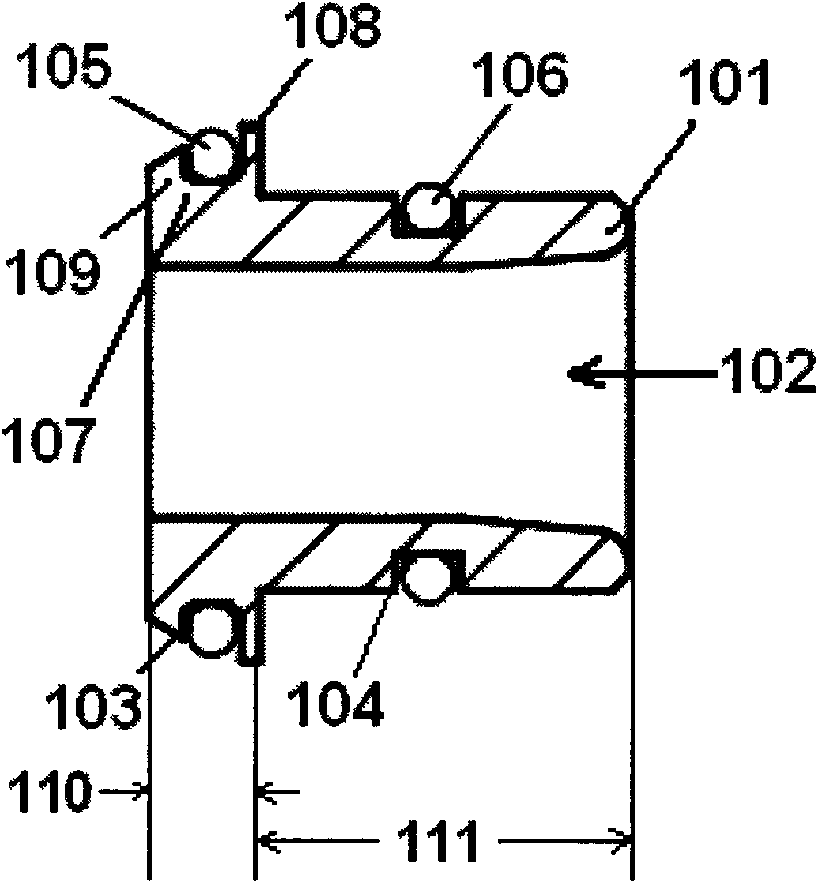

[0053] Such as image 3 A bushing for a pipe joint, comprising a bushing body 101 with an axial channel 102 inside, the bushing body 101 includes a joint connection section 110 for docking with a pipe joint, and a pipe connection section for docking with a pipe 111. A bushing flange is provided on the peripheral outer wall of the joint connection section 110.

[0054] A first O-ring 105 is provided on the joint connection section 110 , and a second O-ring 106 is provided on the pipeline connection section 111 .

[0055] The first positioning structure of the first O-ring 105 is provided on the peripheral outer wall of the joint connection section 110, and the second O-ring 106 is provided on the peripheral outer wall of the pipeline connection section. The second positioning structure, the first positioning structure is the first groove 103 arranged in the circumferential direction, the second positioning structure is the second groove 104 arranged in the circumferential dire...

Embodiment 3

[0059] Such as Figure 5 Pipe fittings shown, including:

[0060] The joint body 1, the interior of the joint body 1 is sequentially arranged along the pipeline insertion direction (direction A):

[0061] Locking cap 5, used to prevent the inner parts from withdrawing;

[0062] The locking cap stopper part 9 is arranged on the pipe insertion end of the joint body, and is used to prevent the locking cap 5 from withdrawing;

[0063] Disassemble the ring 6 to release the locking of the pipeline;

[0064] The snap ring 4 has an annular elastic flange 12 and several latch teeth 10 arranged on the flange 12 for clamping the outer wall of the pipe 13;

[0065] The cone seat 3 is slidingly connected with the inner wall of the joint body 1, and is used to prevent the snap ring 4 from moving in the direction of pipe insertion;

[0066] The cone seat shoulder 8 is provided on the inner wall of the joint body 1, and is used to prevent the cone seat 3 from moving in the direction of pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com