Ultrathin light-guiding film and light-guiding structure thereof

A thin film and ultra-thin technology, applied in the field of lighting, can solve the problem of high production cost, achieve the effects of ultra-thin energy consumption, increase energy utilization rate, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

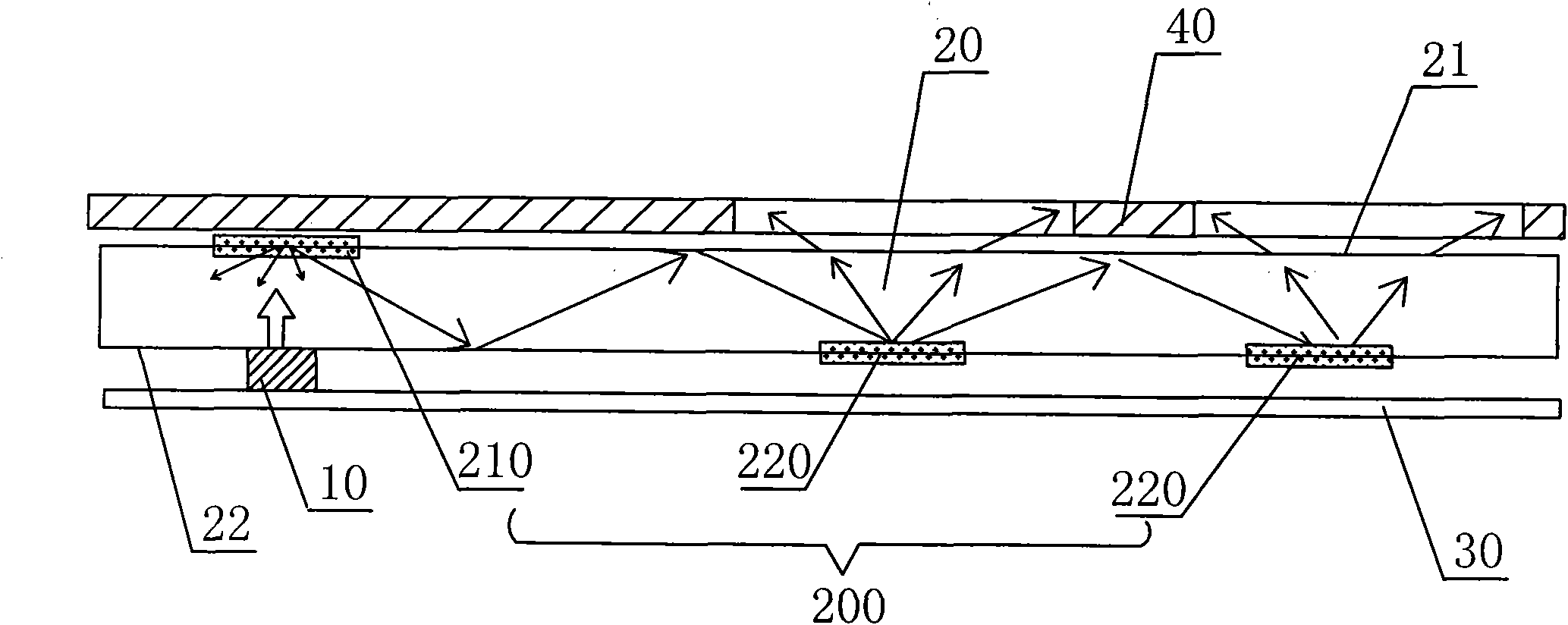

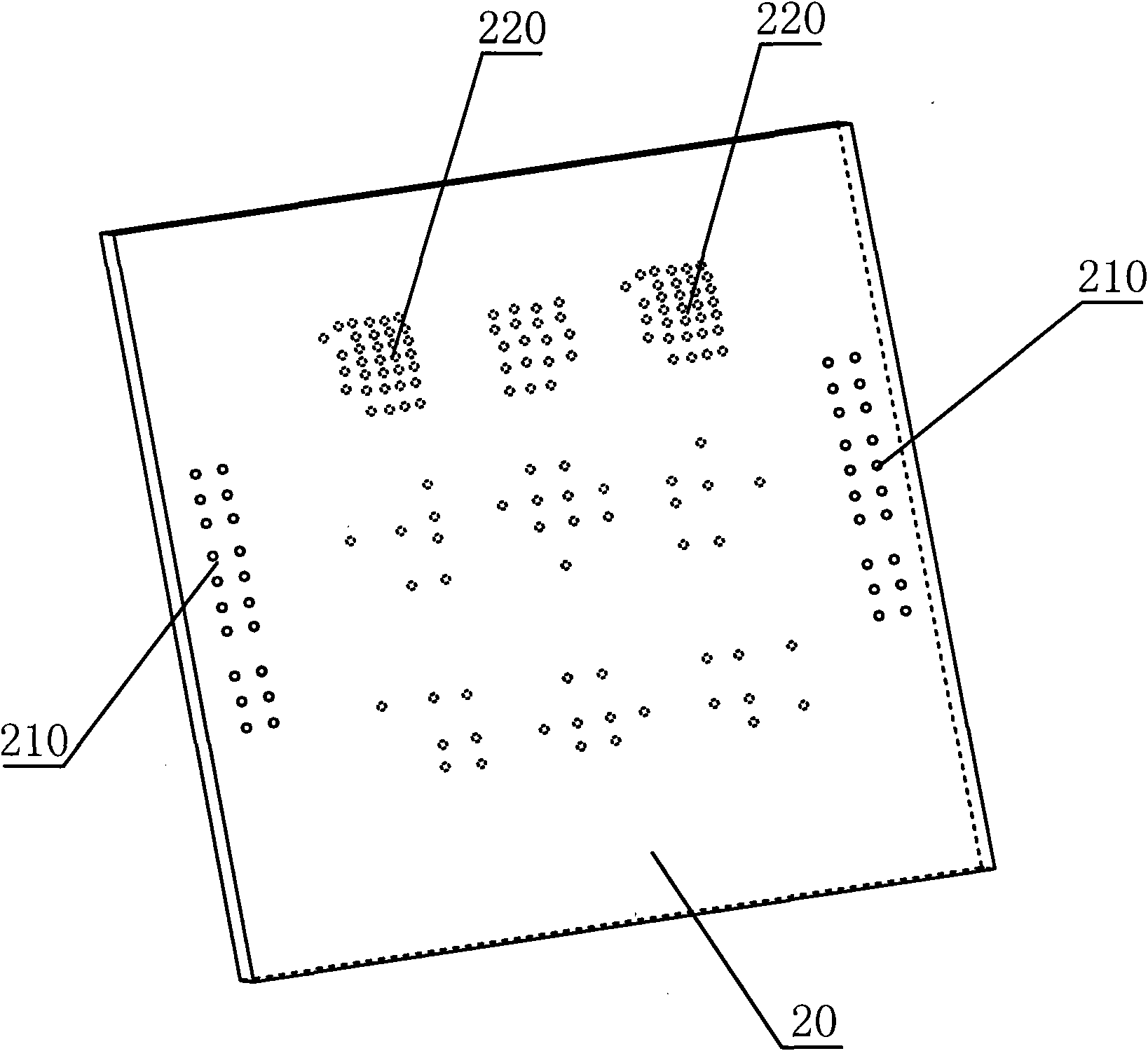

[0023] Please refer to figure 1 as shown, figure 1 It is a cross-sectional view of Embodiment 1 of the light guide structure of the ultra-thin light guide film of the present invention; in this embodiment, a light guide structure of the ultra-thin light guide film includes a light guide film 20, a target area display layer 40 and Top-emitting LED light source 10, the light-emitting surface of the top-emitting LED light source 10 is placed in parallel below the light-guiding film 20, and the target area display layer 40 is tiled on the top of the light-guiding film 20, and the light-guiding film 20 has The first characteristic surface 21 and the second characteristic surface 22, the first characteristic surface 21 and the second characteristic surface 22 are distributed with light guide mesh points 200, and the light guide mesh points 200 include the first characteristic surface 21 distributed on the first characteristic surface 21 A light guide network point 210 and a second ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com