Stone reinforced light type composite board

A composite board and stone technology, applied in the direction of building materials, etc., can solve the problems of occupying large land resources, restrictions, industrial waste finding a way out and affecting sustainable development, etc., to achieve strict processing requirements, reduce specific gravity, and save natural resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

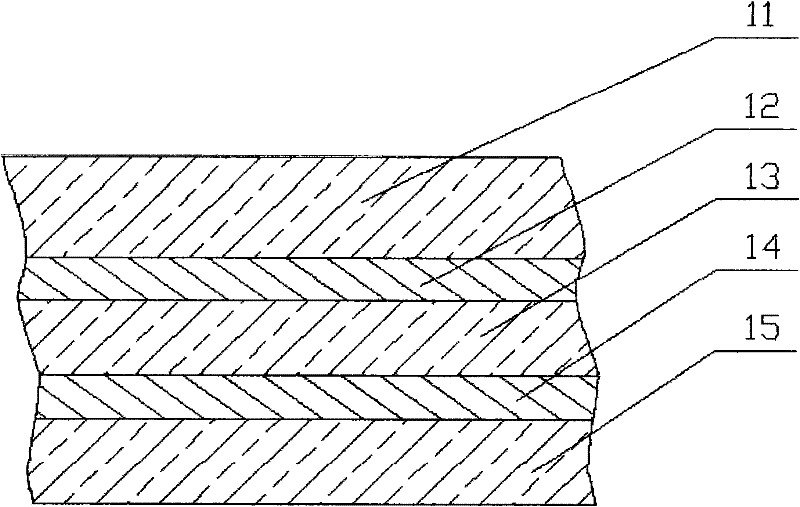

[0019] The preparation method of the side plate can be as follows: laying a layer of the mixed slurry first, then laying a layer of reinforcing layer on the surface of the laid mixed slurry and pasting the reinforcing layer with the mixed slurry below, and then Lay the second layer of mixed slurry on the reinforced layer. When it is necessary to set more layers of adhesive layer and reinforced layer, cycle in this way until the set number of layers of adhesive layer and reinforced layer is reached, and then carry out natural Curing and drying to shape.

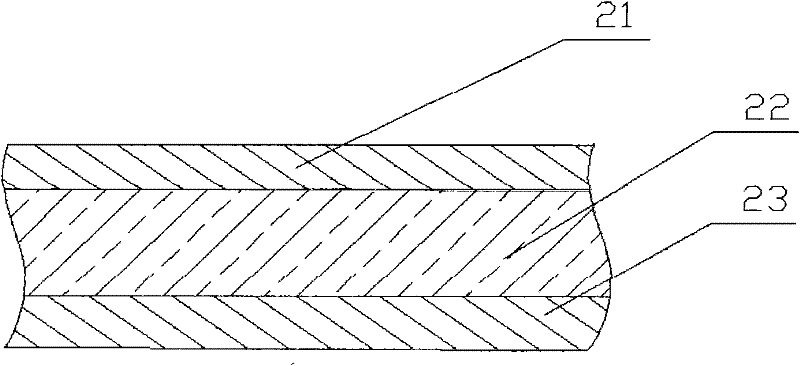

[0020] The core board can be any suitable board material. In order to realize waste utilization, preferably, the core board can use one, multiple or all of the following boards: waste glass steel plate, waste color steel plate, waste hard plastic board, waste rock wool board, waste stone board and foamed cement plate.

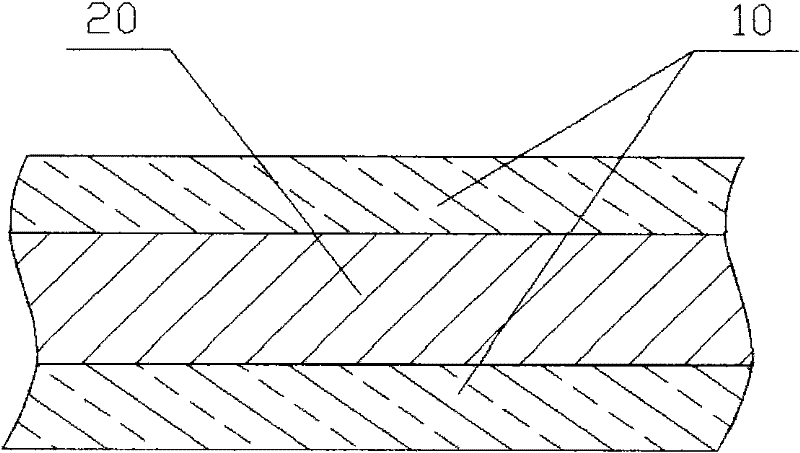

[0021] The number of layers of the core board can be one or more layers, and the multi-layer core boards 2...

Embodiment 1

[0032] Embodiment 1: 25 kilograms of magnesium oxide, 75 kilograms of magnesium sulfate, 40 kilograms of construction waste powder, 30 kilograms of polyurethane plastic powder, 10 kilograms of fly ash, 10 kilograms of rock wool, 10 kilograms of stone powder

Embodiment 2

[0033] Embodiment 2: 41 kilograms of magnesium oxides, 59 kilograms of magnesium chlorides, 100 kilograms of discarded stone materials, 100 kilograms of mixed hard plastics, 100 kilograms of broken glass, 5 kilograms of methylnaphthalene residual oil (calculated by methylnaphthalene, the same below).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com