Manufacturing method of metal oxide semiconductor field effect transistor

An oxide semiconductor and field effect transistor technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., and can solve problems affecting device performance and shortening design dimensions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

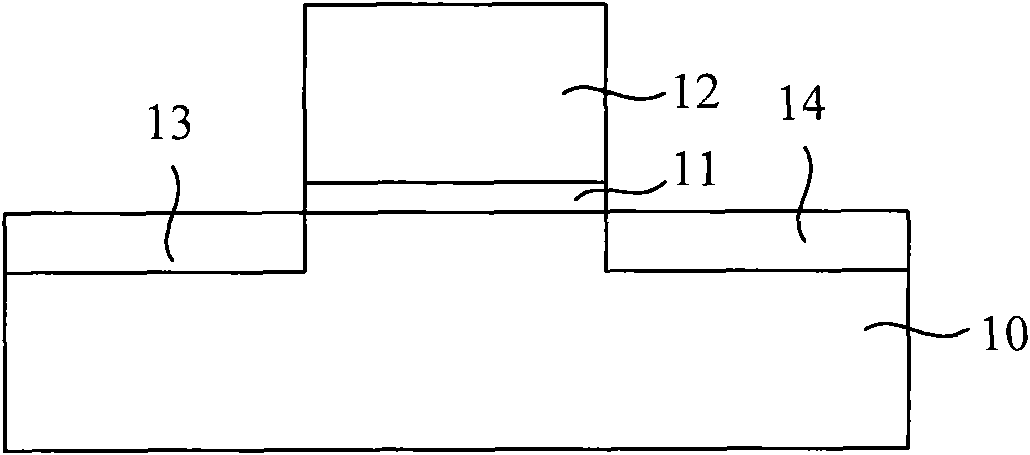

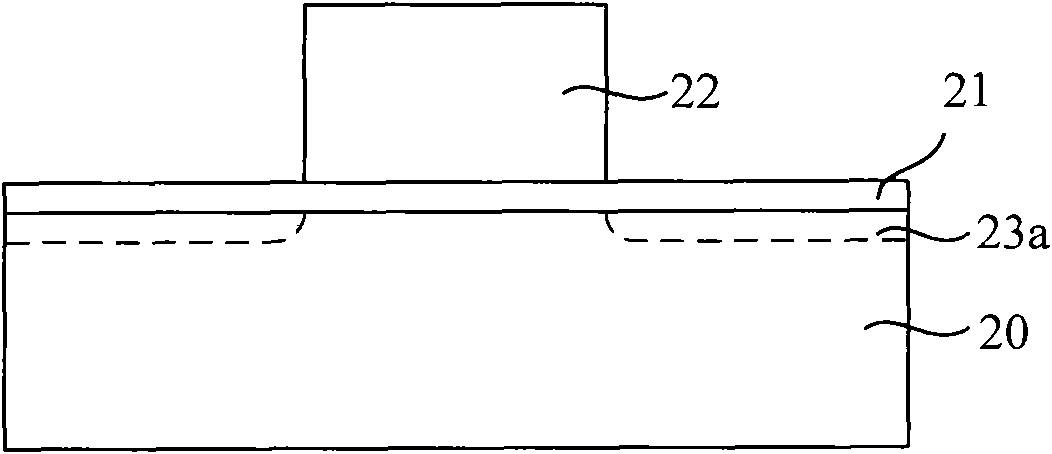

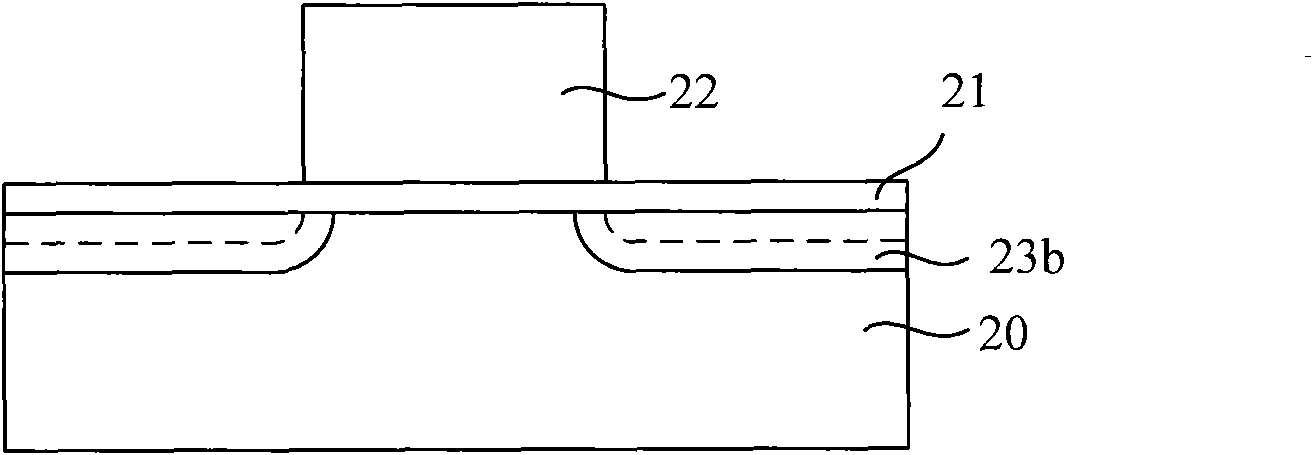

[0023] Reference Figure 5 As shown, an embodiment of the method for manufacturing a metal oxide semiconductor field effect transistor of the present invention includes:

[0024] Step s1, forming a first trench in the substrate;

[0025] Step s2, forming sidewalls on the sidewalls of the first trench;

[0026] Step s3, epitaxially grow a conductive layer in the first trench surrounded by the side wall;

[0027] Step s4, successively perform light doping implantation and source / drain implantation on the substrate to form source / drain regions;

[0028] Step s5, removing the side wall to form a second groove;

[0029] Step s6, forming a gate dielectric layer on the surface of the substrate and the second trench;

[0030] Step s7, forming a gate on the gate dielectric layer.

[0031] In the above embodiment, before forming the gate, the source / drain regions are formed first. By adjusting the process sequence relative to the prior art, the process of the source / drain region can be prevented fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com