Control method of safety controller for welding robot

A safety controller and welding robot technology, applied in the direction of comprehensive factory control, comprehensive factory control, welding equipment, etc., can solve problems such as imperfect functions and unstable performance, and achieve the effect of improving flexibility and reducing connection complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

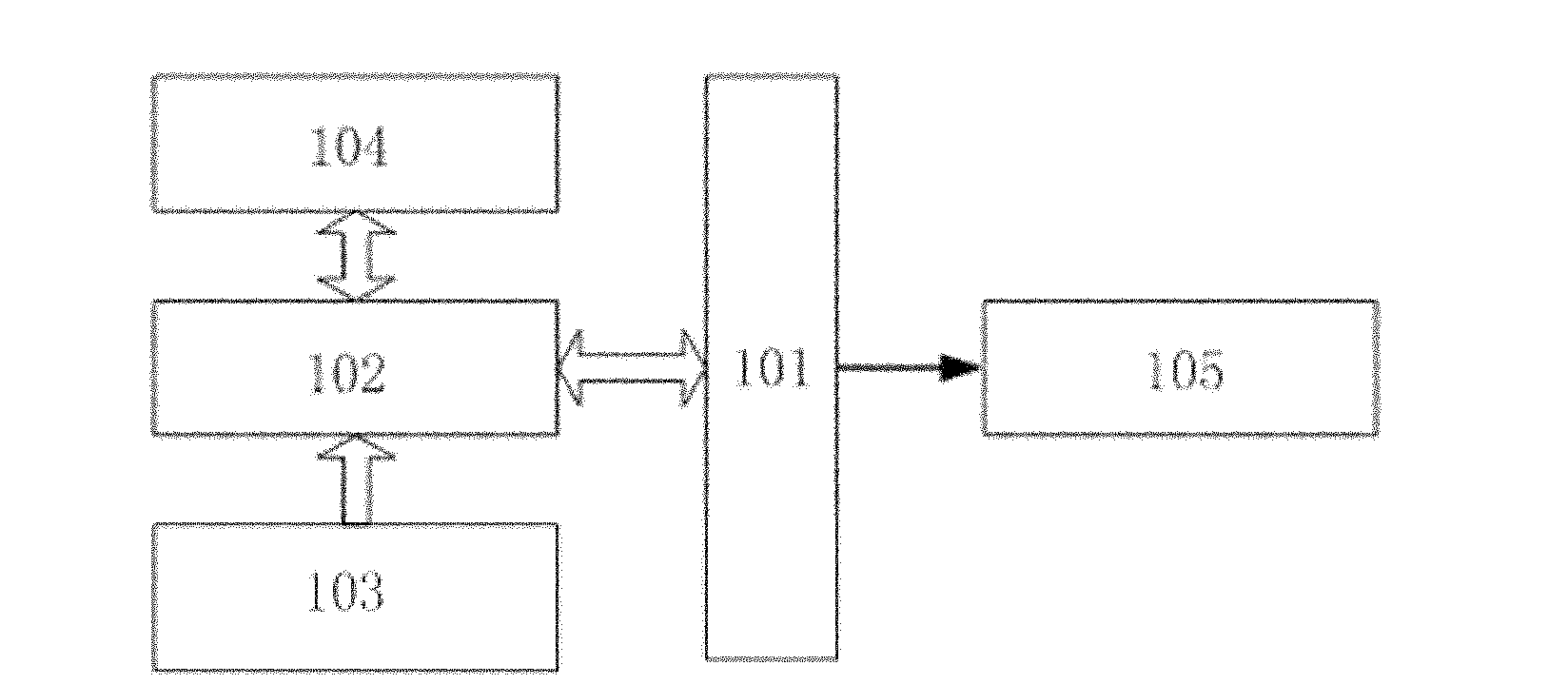

[0031] see figure 1 , the present invention includes a safety protection module 101 , a host computer 104 , an execution module 105 , an operation information collection module 103 and a field bus 102 .

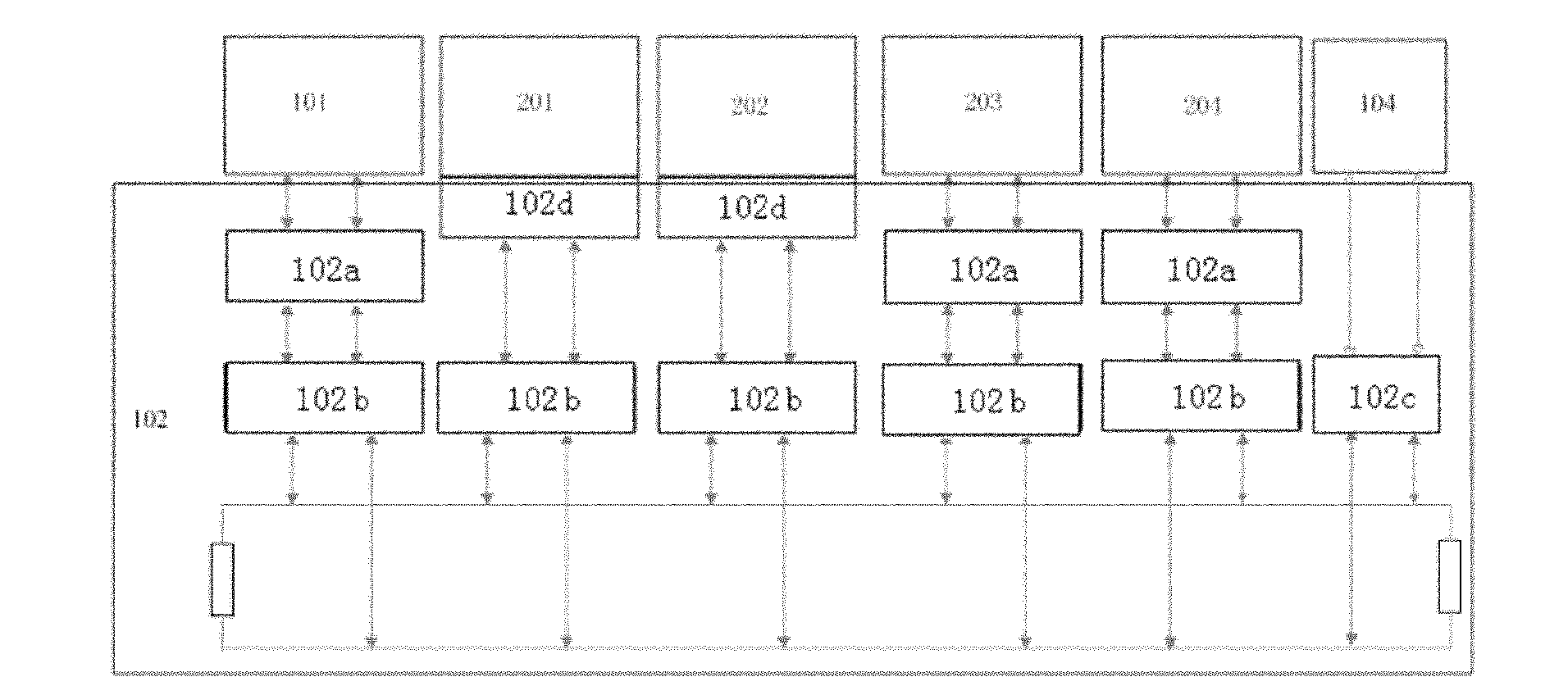

[0032] Among them, the security protection module 101 is a central processing unit, which is used to formulate and execute various security protection strategies at various levels, and usually adopts a microcontroller integrating various external interfaces. In this embodiment, the security protection module 101 adopts an ARM9 micro-controller The device chip S3C2440A has built-in rich peripheral resources including interrupt controller, GPIO, SPI and other interface circuits.

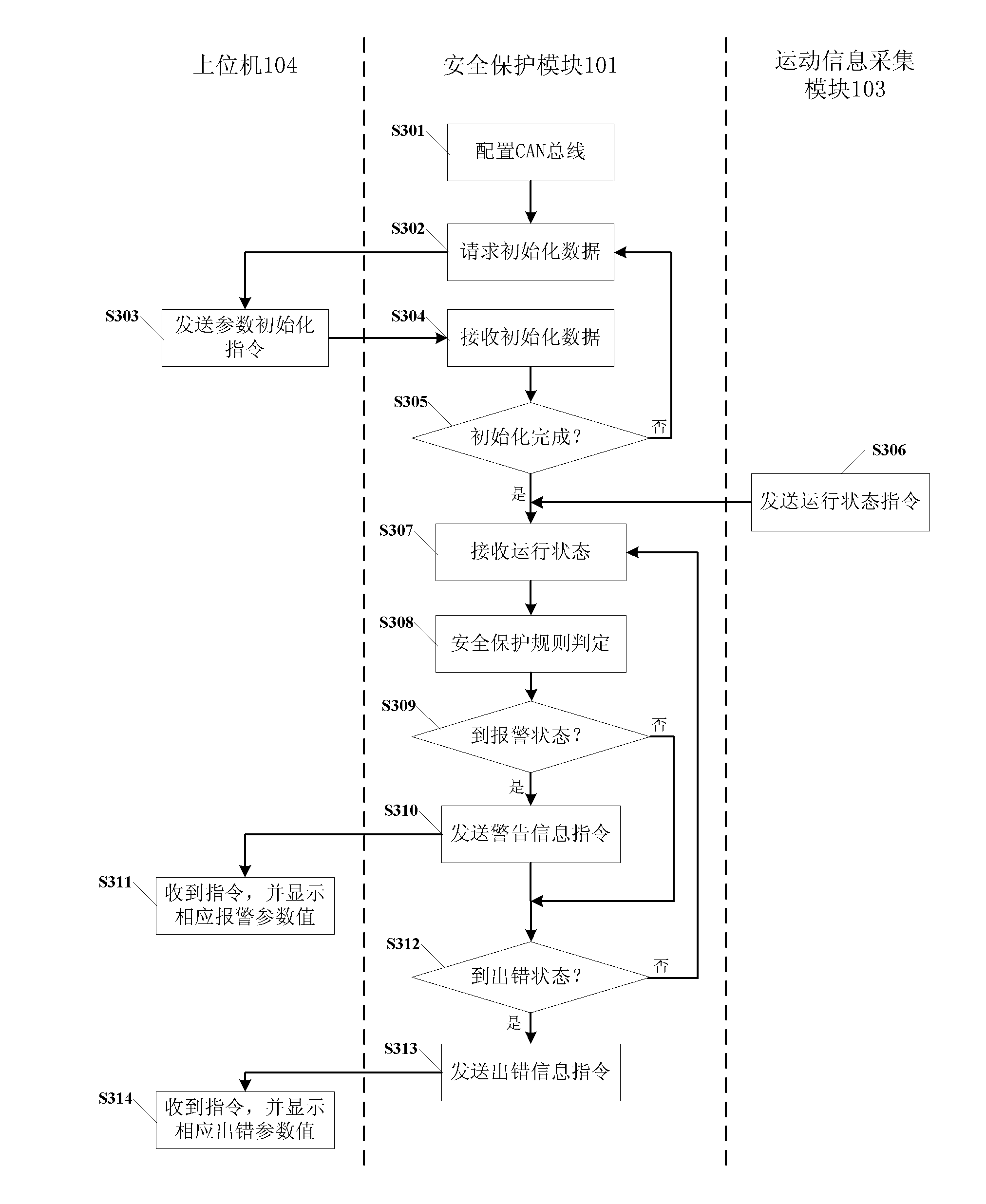

[0033] The upper computer 104 can be used to display the alarms and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com