Machining clamp for cam bearing cover of automobile engine

A technology for automobile engines and cam bearings, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc. damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

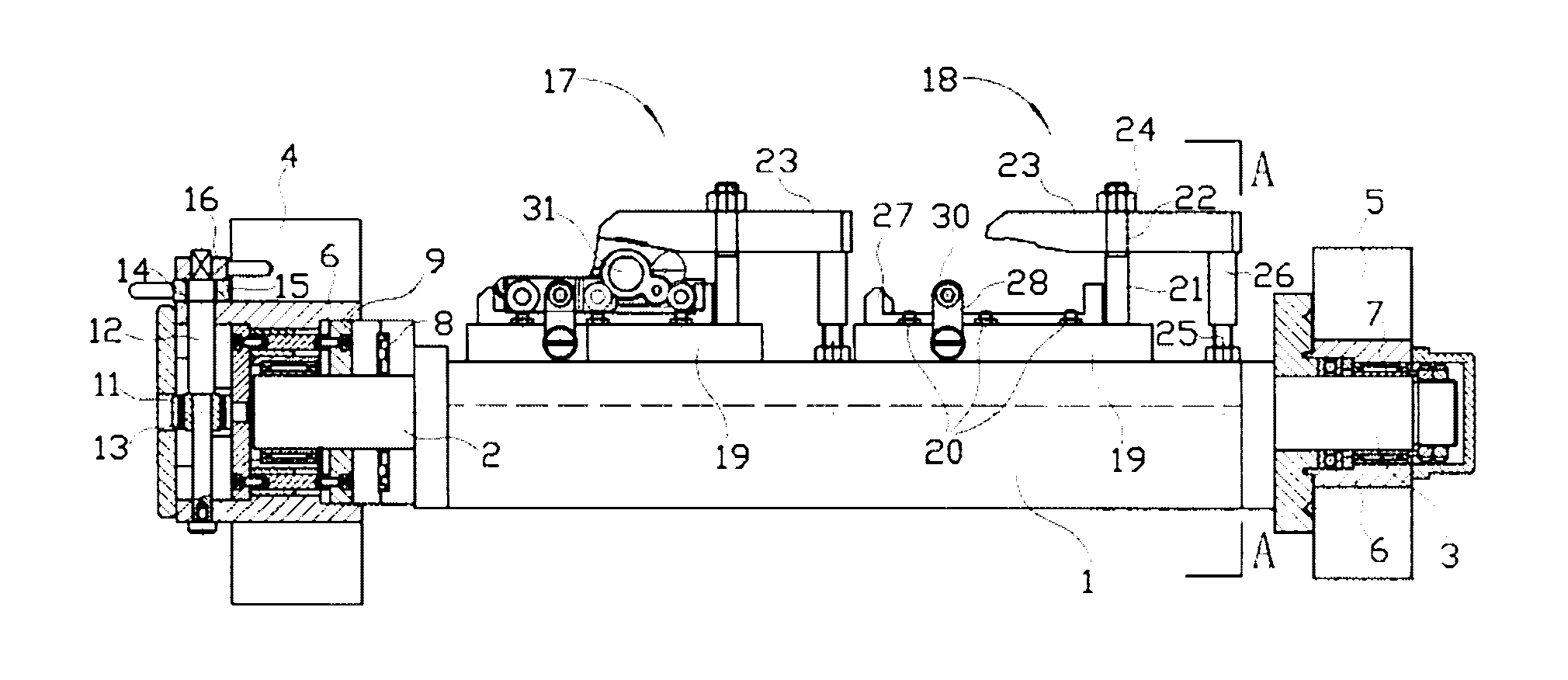

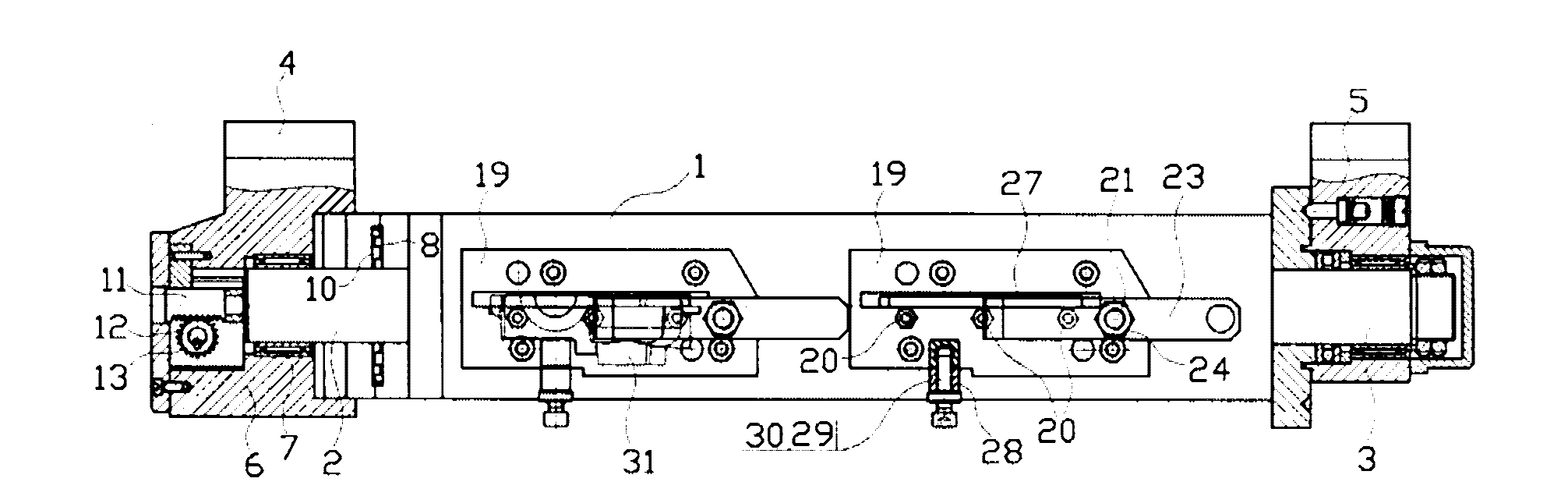

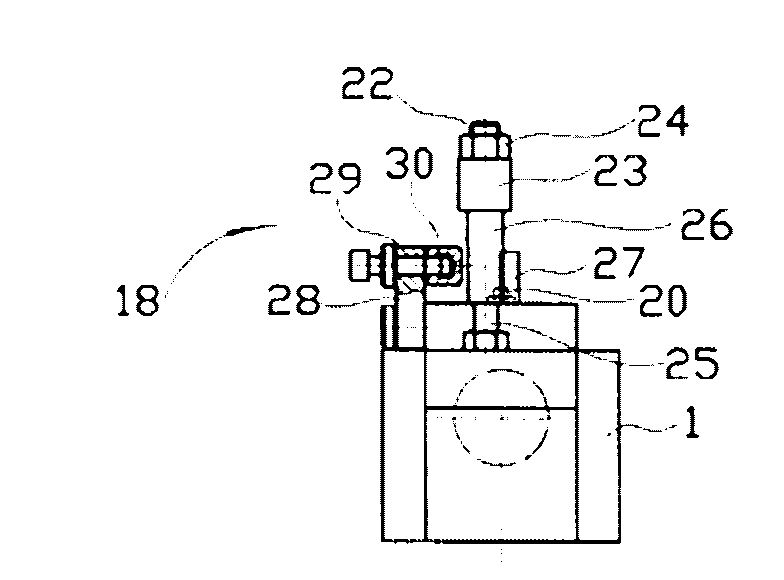

[0014] Figure 1~Figure 3 Among them, the automobile engine cam bearing cover processing card has a groove-shaped clamping body 1, the left and right ends of the clamping body are respectively connected with clamping body shafts 2 and 3 along the length direction of the clamping body, and the left and right clamping bodies The axes of the shafts are on the same straight line, the left and right clamping body shafts have shaft seats 4 and 5 respectively, the shaft seats have a shell 6, and there is a bearing 7 between the shell and the clamping body shaft, and the left clamping body shaft seat There is a toothed disc rotation positioning device, and the toothed disc rotation positioning device has a toothed plate 8 on the end face of the clamping body that is positioned on the left end surface of the clamping body, and the axis is on the same line as the axis of the clamping body. There is an end sprocket frame 9 that can move along the axial direction of the clamping body shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com