Main shaft knife loosening and unloading mechanism

A spindle and knife loosening technology, applied in metal processing machinery parts, clamping, support and other directions, can solve the problems of destroying the rotation accuracy of the spindle bearing and reducing the service life of the bearing, so as to prolong the service life, improve the stress condition, and improve the maintenance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

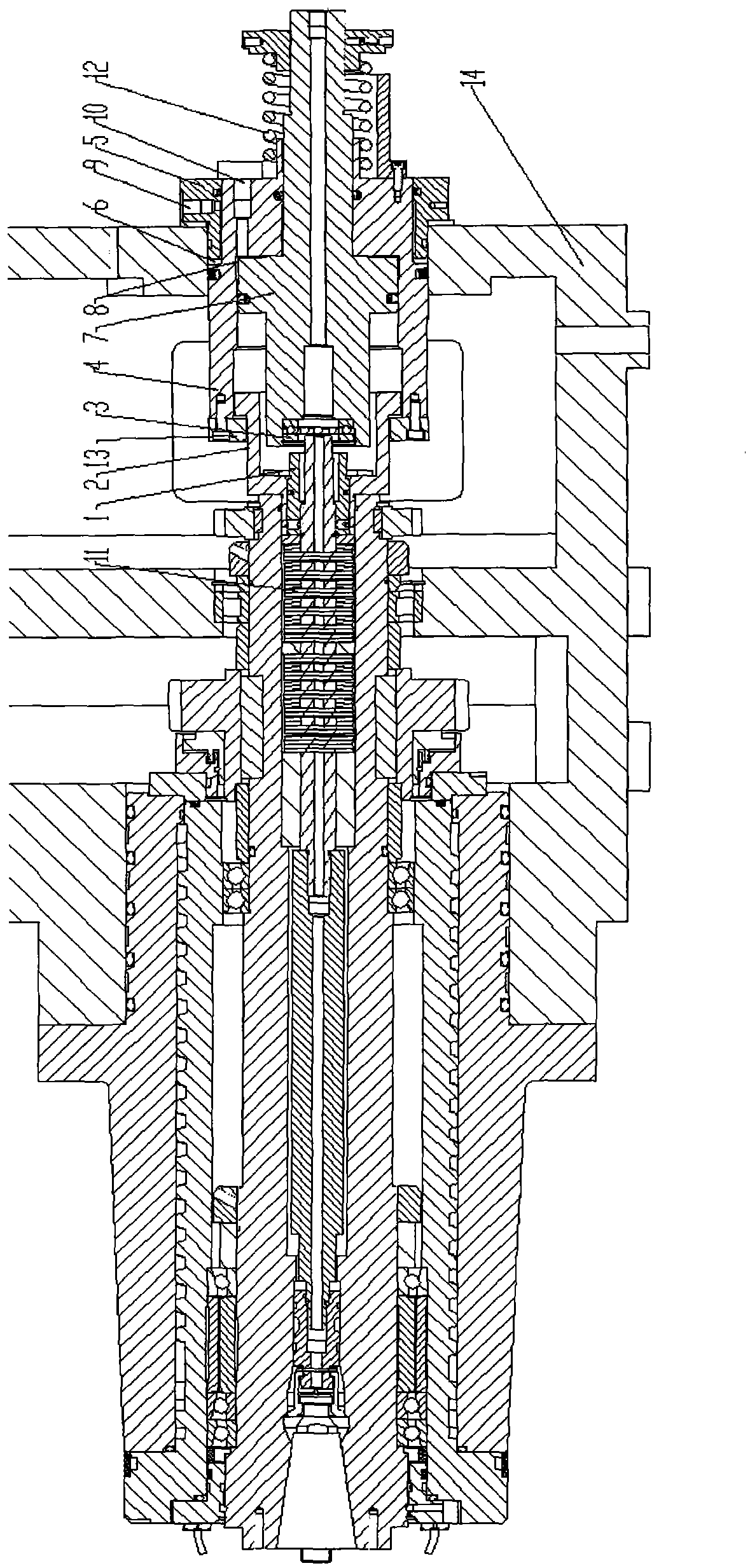

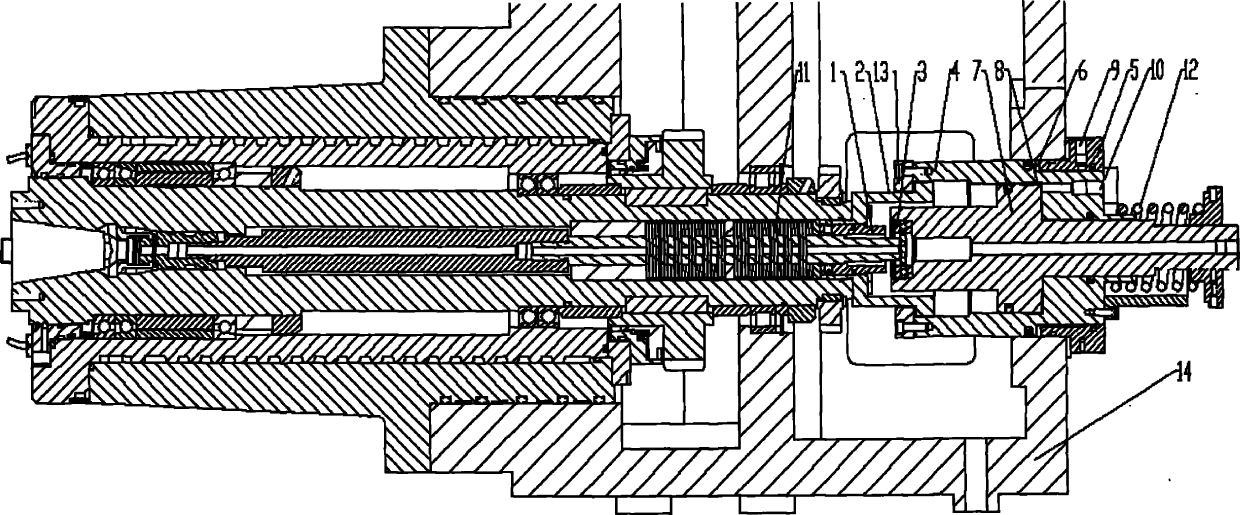

[0009] The structure of the spindle tool unloading mechanism, such as figure 1 As shown, it is characterized in that a gland 2 for unloading is fixed on the rear end of the main shaft, the nut 1 is fixed on the broach rod, the thrust bearing 3 of the loosening structure is fixed on the front end of the piston 7, and the piston 7 is placed in the cylinder 4 , the unloading plate 13 fixed with the cylinder body 4 is placed on the upper surface of the boss of the gland 2 to form an overlap, the cylinder liner 5 is fixedly installed on the headstock 14, and is in the same installation hole of the unloading mechanism as the cylinder body 4 . The unloading mechanism mounting hole and the spindle mounting hole are processed on the spindle box 14; the cylinder body 4, the cylinder liner 5 and the unloading mechanism mounting hole on the spindle box 14 jointly form an anti-closed oil chamber 6, and the outer circumference of the tail end of the piston 7 is connected to the cylinder bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com